Busbarless crystalline silicon cell and its application

A crystalline silicon cell and cell technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as cell area waste, avoid waste, reduce shading area, and increase power generation per unit area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

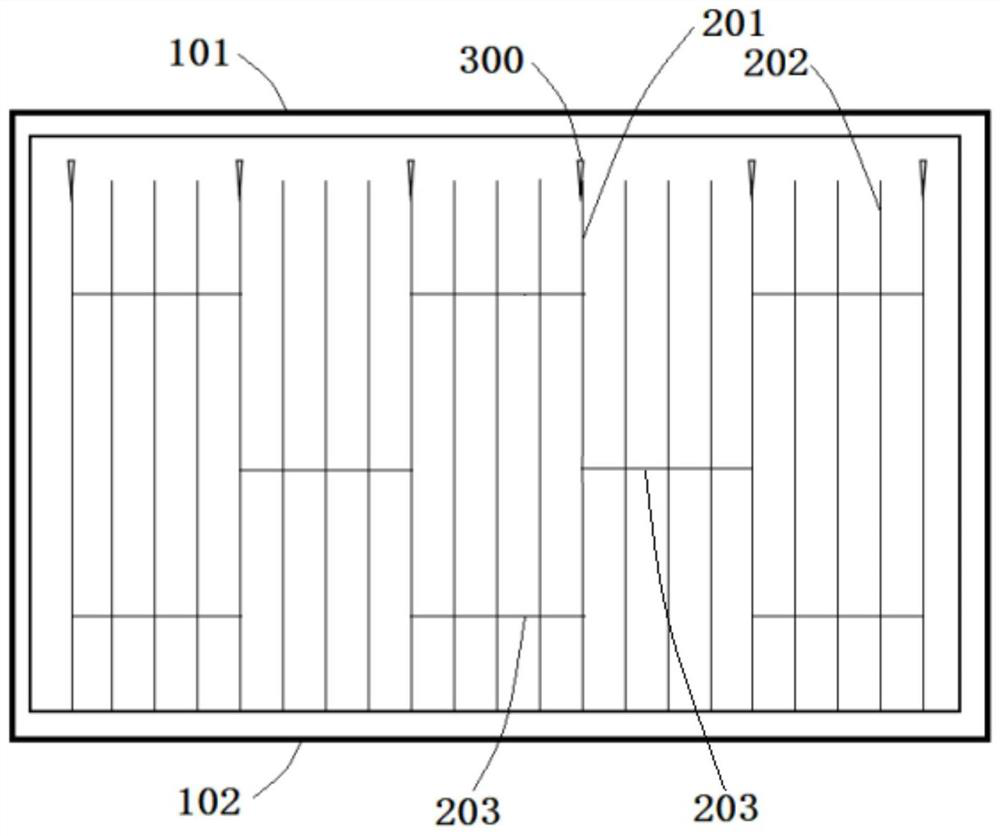

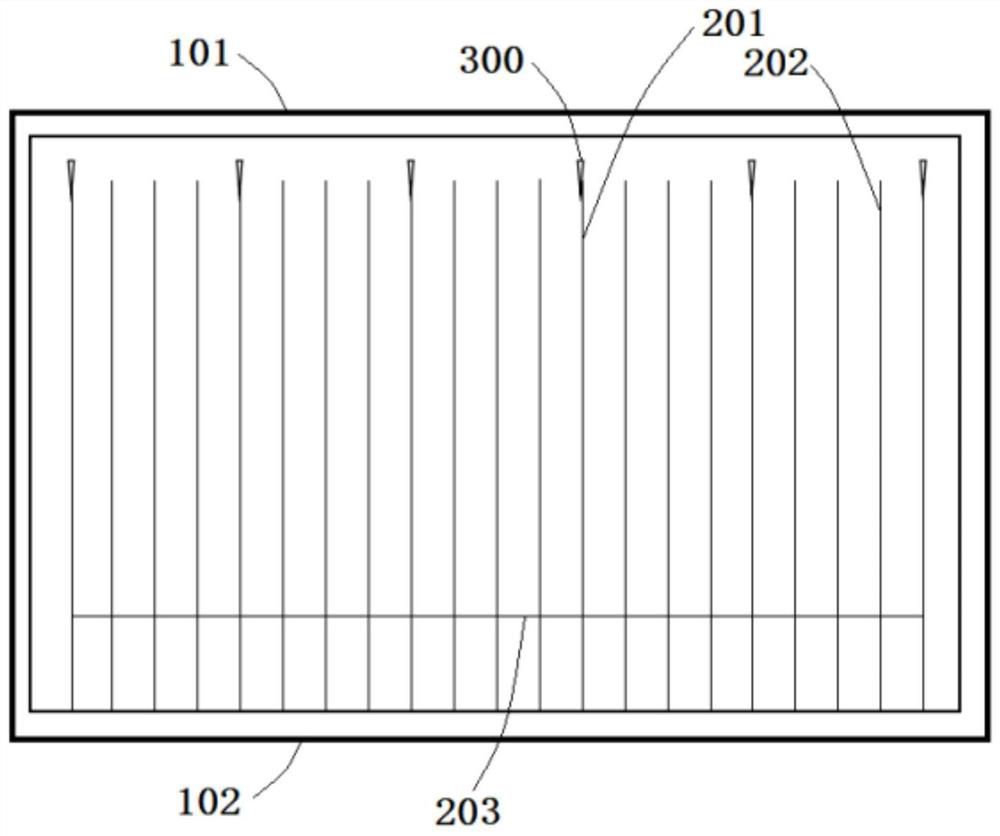

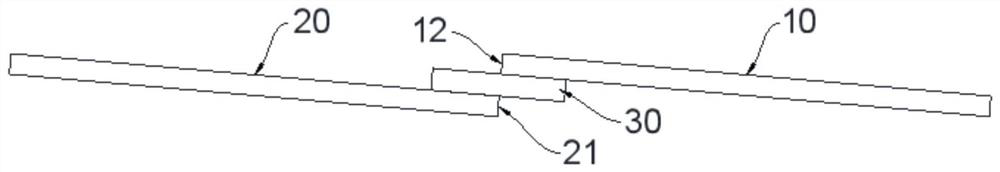

[0031] Such as figure 1 and figure 2 As shown, the present invention provides a busbar-free crystalline silicon battery sheet, which is rectangular as a whole, and the battery sheet includes a pair of sides parallel to each other: the first side line 101 and the second side line 102; the first side line 101 and the second side line 102 The second side line 102 is the long side of the battery sheet; the four corners of the battery sheet are right angles (the four corners of the battery sheet can also be rounded); the back of the battery sheet is provided with a back electrode;

[0032] The front of the battery sheet is provided with a plurality of first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com