LED lamp bead with reflection cup

A technology of LED lamp beads and reflector cups, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of accelerated aging of LED chips 02, low light efficiency of LED lamp beads, and high temperature of LED lamp beads, so as to reduce temperature and increase Heat sink and heat dissipation area, the effect of improving the light output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the features, technical means, specific objectives and functions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

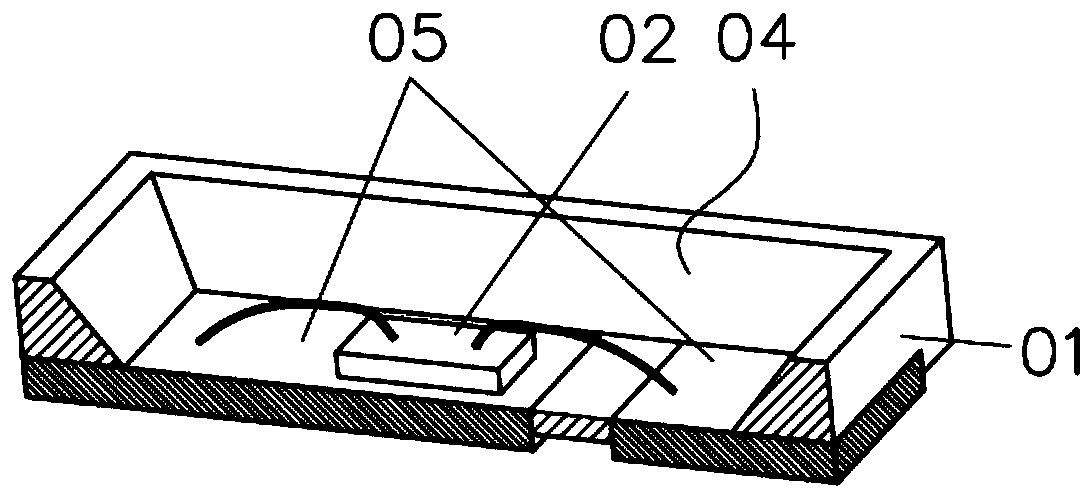

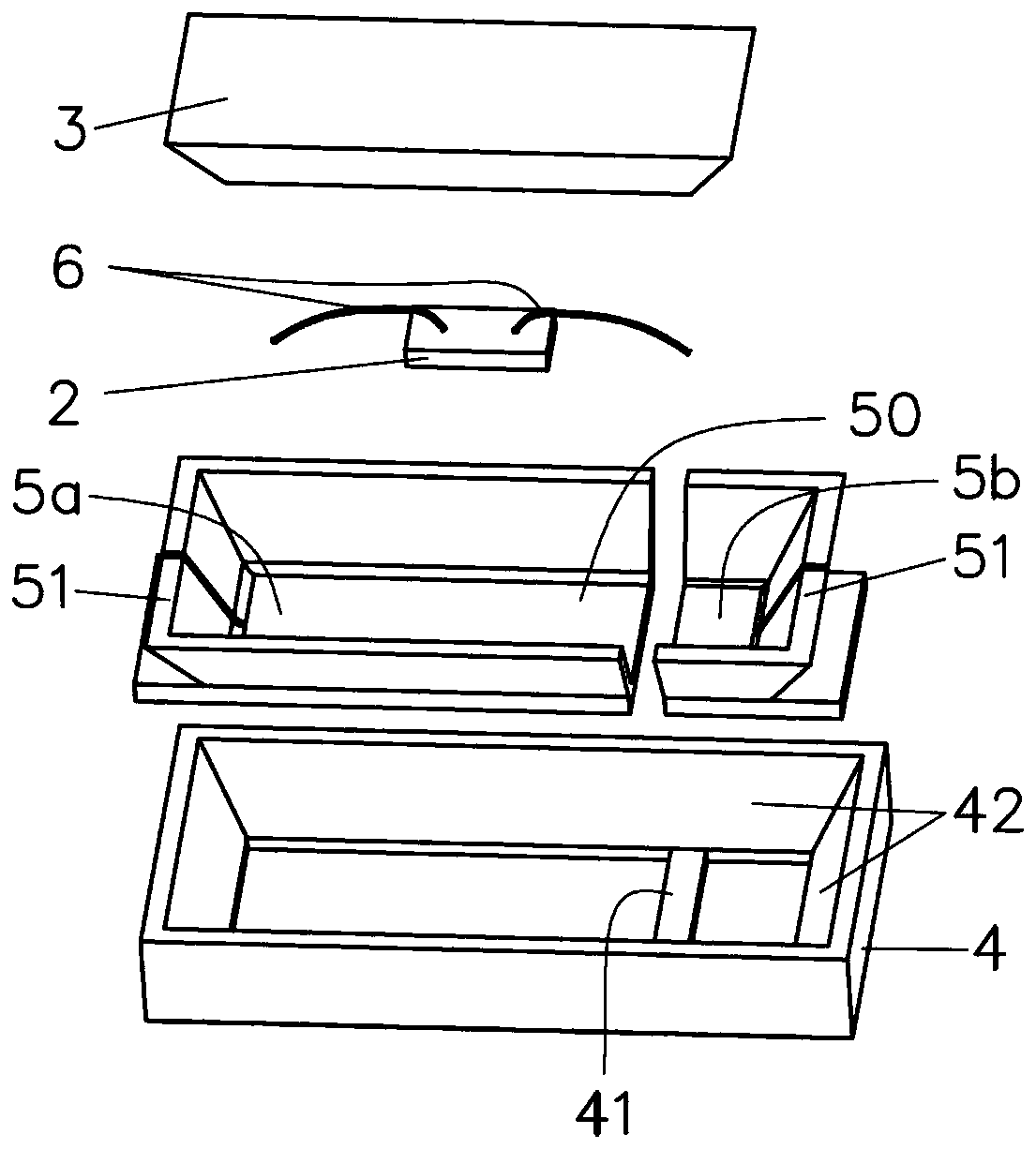

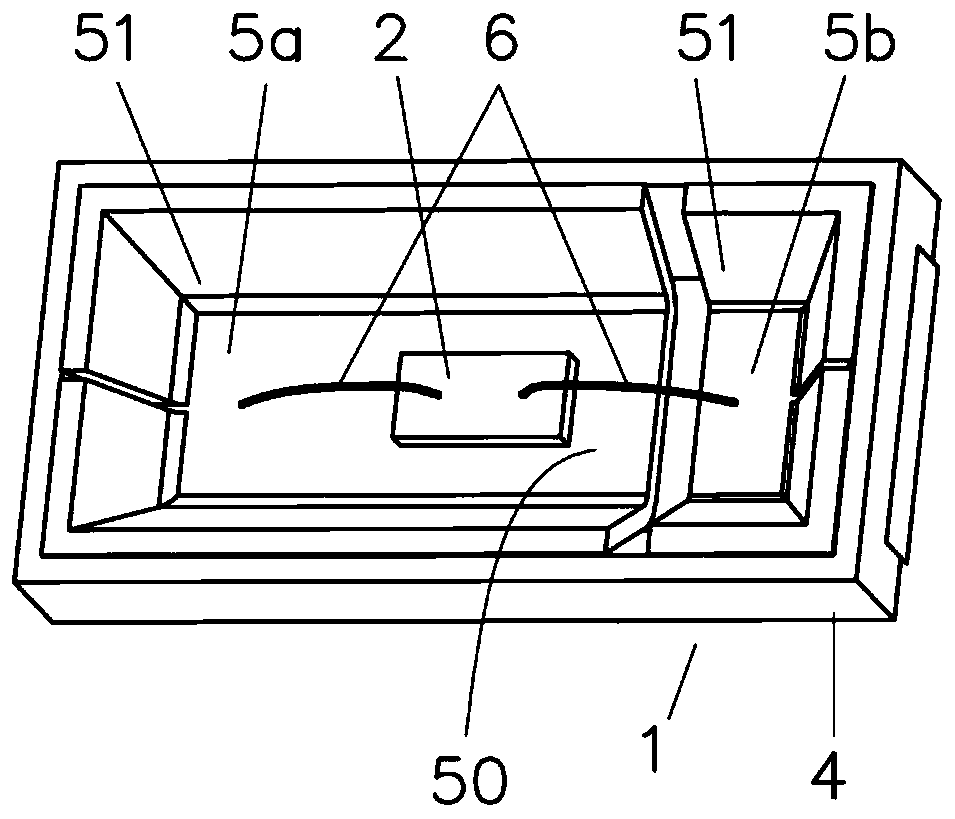

[0011] refer to figure 2 , image 3 and Figure 4 . An LED lamp bead with a reflective cup includes a bracket 1, an LED chip 2 installed in the bracket 1, and a resin 3 covering the LED chip 2. The bracket 1 includes an injection-molded cup 4 and positive and negative pads 5 a / 5 b disposed in the cup 4 . The cup bowl 4 includes a bottom wall 41 , and a horn-shaped side wall 42 is formed around the bottom wall 41 . Both or one of the positive and negative pads 5a / 5b is provided with a reflective portion 51 extending along the side wall 42 and attached to the side wall 42 . When one of the positive and negative pads 5a / 5b is provided with a reflective portion 51, the reflective portion 51 constitutes a half h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com