Paste resin drying production control method

A production control method and paste resin technology, which are applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of latex foaming, low flow rate of atomizer and easy blockage, etc., to reduce foam and realize safe production operation. , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation

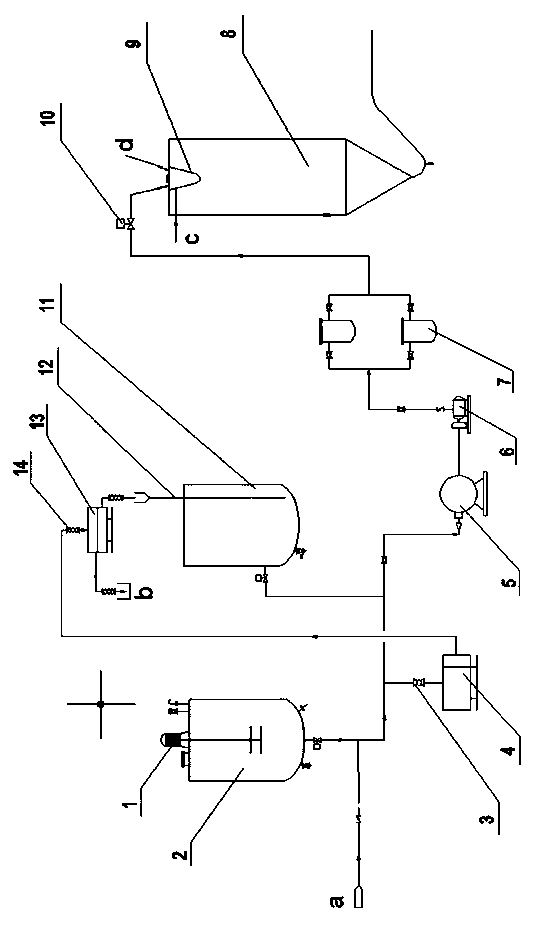

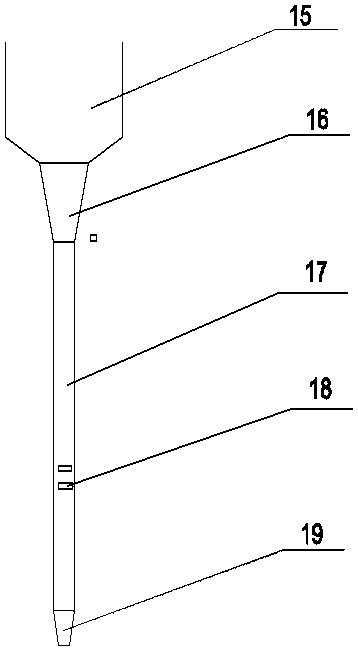

[0020] As shown in Figure 1-2, a paste resin drying production control method, including sequentially connected latex receiving tank (2), dump pump (4), vibration mechanism (13), middle tank (11), pulverizer ( 5), latex quantitative pump (6), filter (7), atomizer (9) and drying tower (8); the latex after the reaction in the polymerization process enters the latex receiving tank (2) and then is discharged by the pump (4) Drive into the vibrating mechanism (13), the sieved latex enters the middle tank (11), is further pulverized by the pulverizer (5), and then sent to the filter (7) by the latex quantitative pump (6) for filtration, and finally sent to the atomization The device (9) disperses the latex into small droplets for drying.

[0021] Another embodiment differs in that the vibrating mechanism (13) is a liquid vibrating screen.

[0022] Another embodiment is different in that the inlet and outlet of the vibrating mechanism (13) are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com