A two-stage desert sand filter and its wastewater treatment method

A technology for wastewater treatment and sand filter, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, difficult loading and unloading of packing, complicated maintenance, etc. The effect of operating costs, reducing capital investment costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

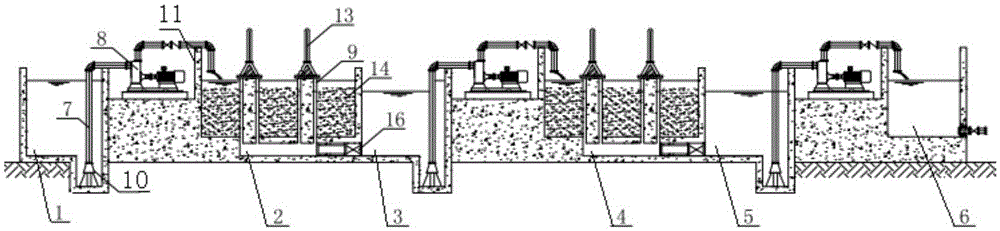

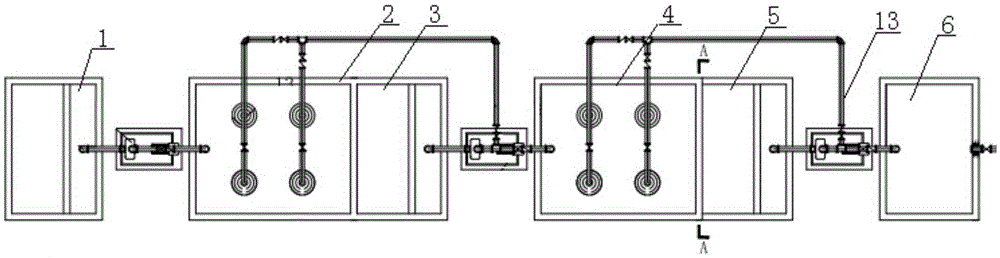

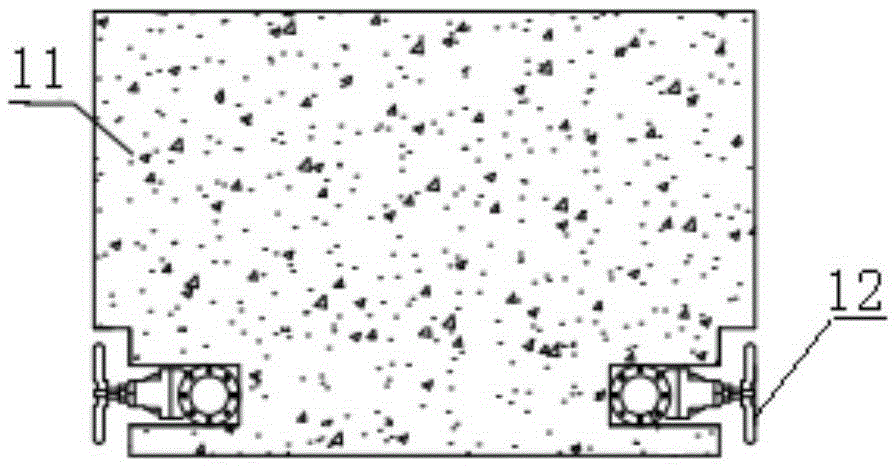

[0039] Such as figure 1 , 2 , a two-stage desert sand filter, which includes a regulating pool 1, a first-level desert sand filter 2, a first-level water storage tank 3, a second-level desert sand filter 4, a second-level water storage tank 5 and a third-level water storage tank 6 connected in sequence ; The bottom of the adjustment pool 1 is provided with a water absorption bell mouth 10 connected to the lifting pipeline 7, and the lifting pipeline 7 lifts the waste water to the first-level desert sand filter tank 2 through the lifting pump 8; the first-level desert sand filter tank 2 is provided with a filter material 14 and filter column 9; the structure of the primary storage tank 3 is the same as that of the regulating tank 1, the structure of the secondary desert sand filter 4 is the same as that of the desert sand filter 2, and the bottom of the primary storage tank 3 is provided with a connection with the lifting pipe 7 The water-absorbing bell mouth 10, the lifting p...

Embodiment 2

[0049] In this embodiment, based on the two-stage desert sand filter in the above-mentioned embodiment 1, the following effluents are treated for wastewater. A degreasing phosphating wastewater (COD: 160-180mg / L, phosphate (calculated as P): 84-108mg / L, pH value: 4.2-5.1, petroleum: 163-215mg / L, Zn + : 35-40mg / L) After chemical precipitation, flocculation and air flotation, the effluent water quality is COD: 72-81mg / L, phosphate (calculated as P): 6.6-10.8mg / L, pH value: 4.9-5.8, petroleum Class: 12-23mg / L, Zn + : 4.7-6.2mg / L,

[0050] This embodiment is based on the wastewater treatment method of the above-mentioned embodiment 1, and the basic operating parameters: the daily treatment water volume Q is 3000m 3 / d; filter material layer height H 1 1.1m (1.0≤H 1 ≤1.5m); water depth H on the sand surface 2 is 1.5 (1.0≤H 2 ≤1.5m); super high H 3 0.6m (0.6≤H 3 ≤0.8m); wall thickness H 4 is 0.2(0.2≤H 4 ≤0.3m); the height of the water channel H 5 is 0.5 (0.4≤H 5 ≤0.8); w...

Embodiment 3

[0053] In this embodiment, based on the two-stage desert sand filter in the above-mentioned embodiment 1, the following effluents are treated for wastewater. A printing and dyeing wastewater (COD Cr : 1150-1250mg / L, BOD 5 : 210-260mg / L, chromaticity: 400-500 times, pH value: 9.2-11.6, SS: 1800-2200) after suspending and attaching biological anaerobic-aerobic-micro-flocculation treatment, the effluent water quality is COD Cr : 150-360mg / L, BOD 5 : 70-80mg / L, chromaticity: 100-140 times, pH value: 8.5-9.4, SS: 200-400,

[0054] This embodiment is based on the wastewater treatment method of the above-mentioned embodiment 1, and the basic operating parameters: the daily treatment water volume Q is 3000m 3 / d; filter material layer height H 1 1.5m (1.0≤H 1 ≤1.5m); water depth H on the sand surface 2 1.1m (1.0≤H 2 ≤1.5m); super high H 3 0.8m (0.6≤H 3 ≤0.8m); wall thickness H 4 is 0.3(0.2≤H 4 ≤0.3m); the height of the water channel H 5 is 0.8 (0.4≤H 5 ≤0.8); water backwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com