A method of using a station material distribution device

A station and equipment technology, which is applied in the field of station material distribution equipment, can solve the problems of being mixed in one basket at the same time, the parts are disorderly, and the assembly efficiency is low, so as to achieve the effects of high assembly efficiency, improved work efficiency, and flexible material distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

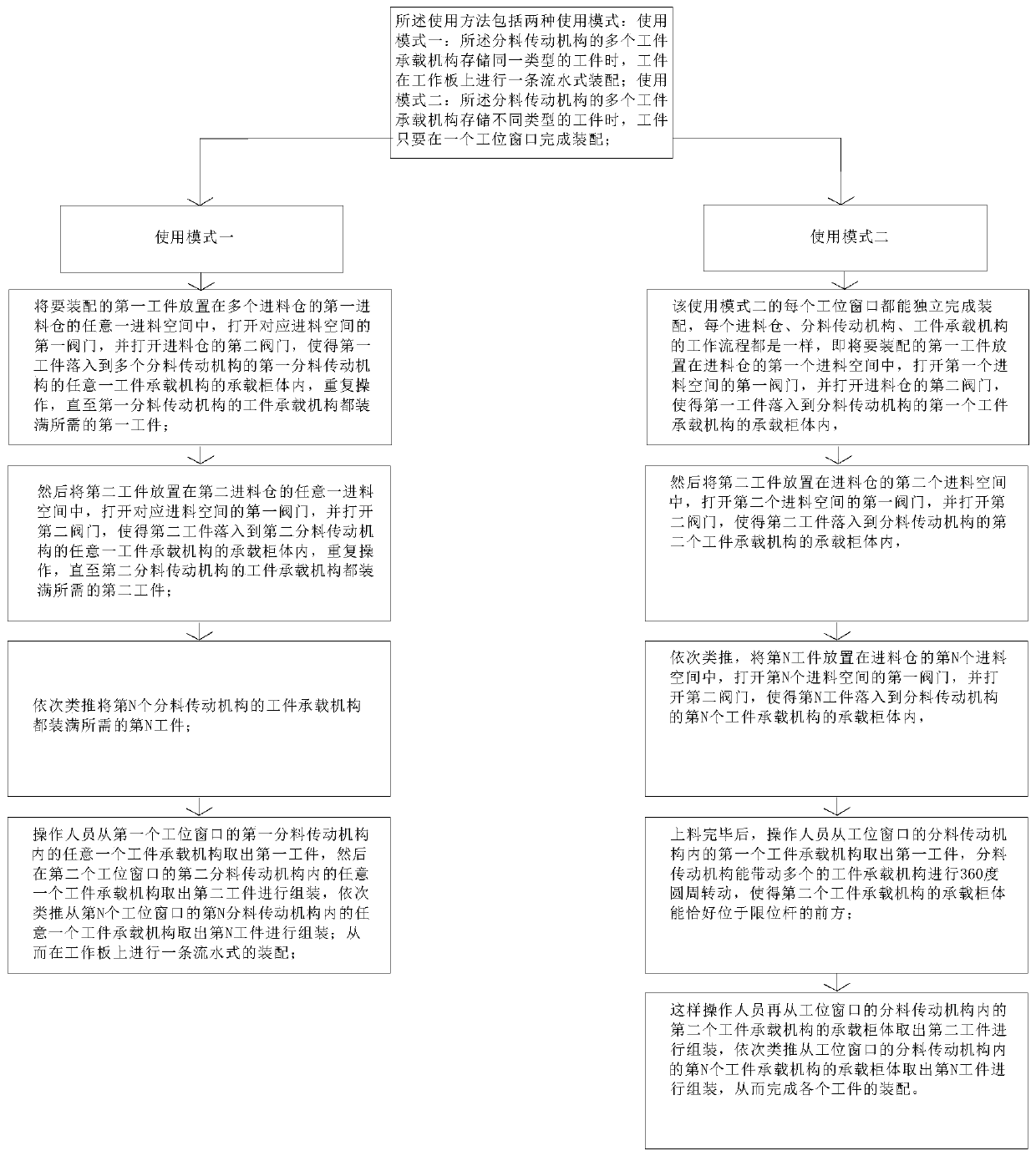

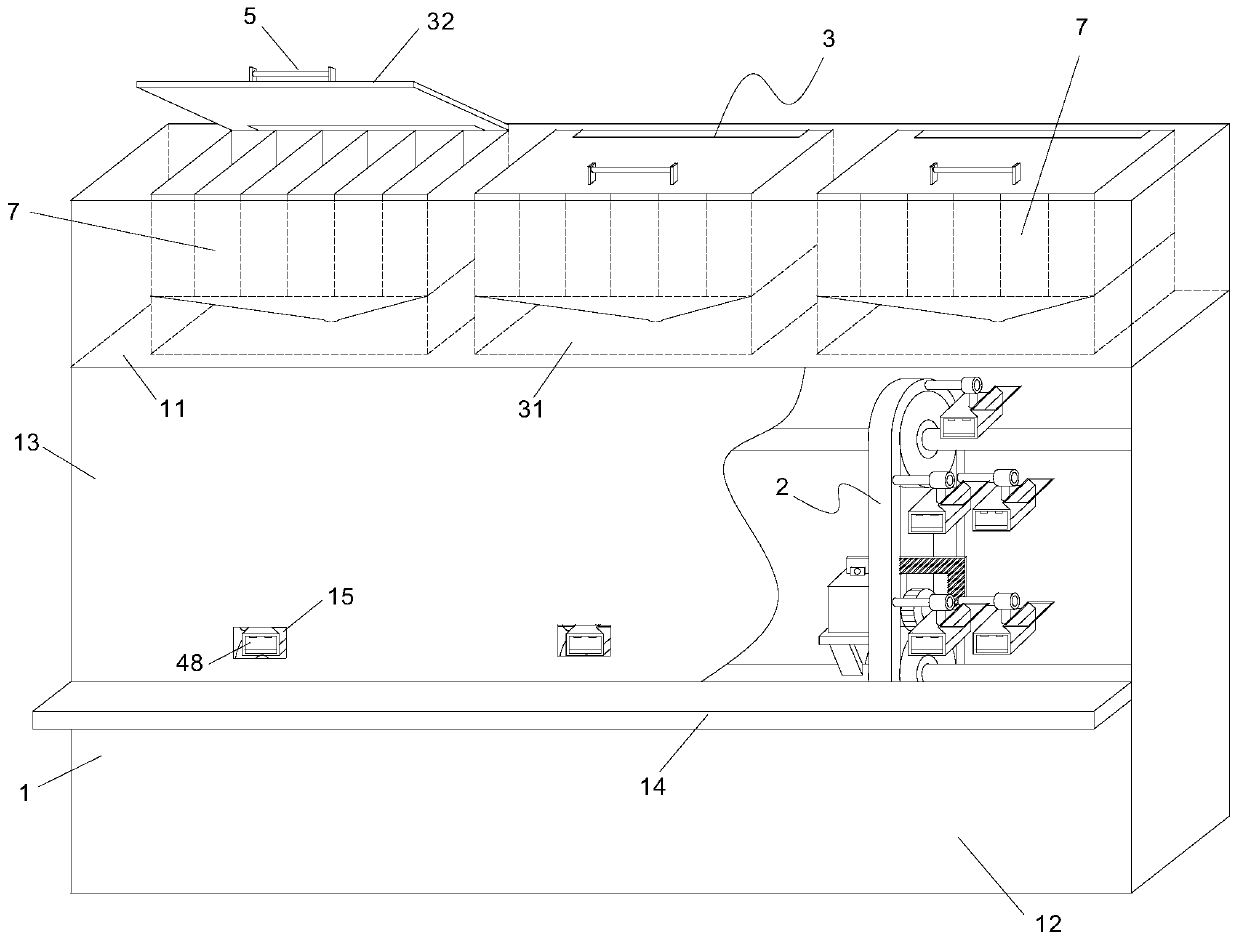

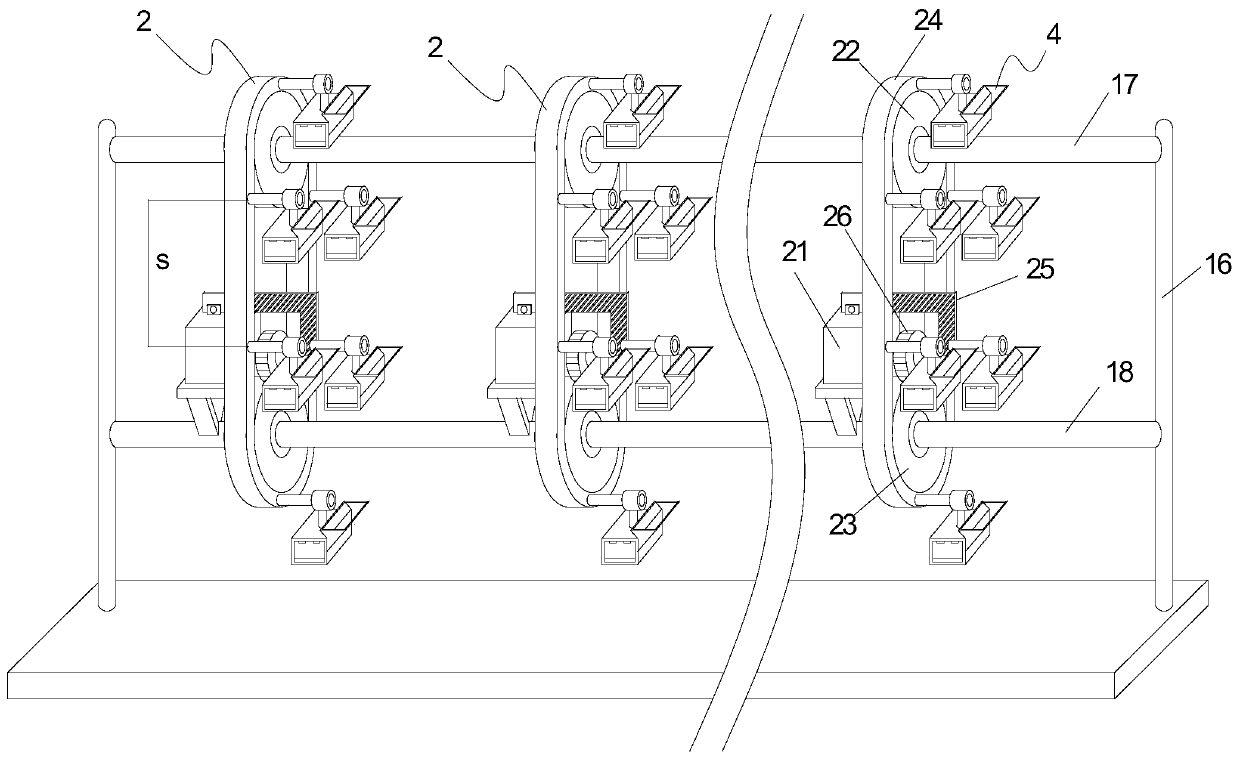

[0026] see Figure 1 to Figure 6 As shown, the present invention provides a method for using station material distribution equipment, including a material distribution workbench 1, a first partition 11 is arranged in the material distribution workbench 1, and the first partition 11 will The material distribution workbench is separated into a lower space 12 and an upper space 13, a work plate 14 is arranged on the front side wall of the material distribution workbench 1, and a plurality of station windows 15 are provided on the front side wall of the material distribution workbench 1 , the station window 15 is located above the work plate 14; in this way, the operator can operate on the station window of the work plate, and a support rod 16 is vertically arranged on both sides of the inner bottom plate of the material distribution workbench 1, The support rods 16 are l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com