Feeding amount adjusting device

A technology for adjusting device and feeding amount, applied in the directions of transportation and packaging, loading/unloading, etc., it can solve the problems of uneven material, uncertainty, unstable transport speed of belt conveyor, etc., and achieve convenient operation and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

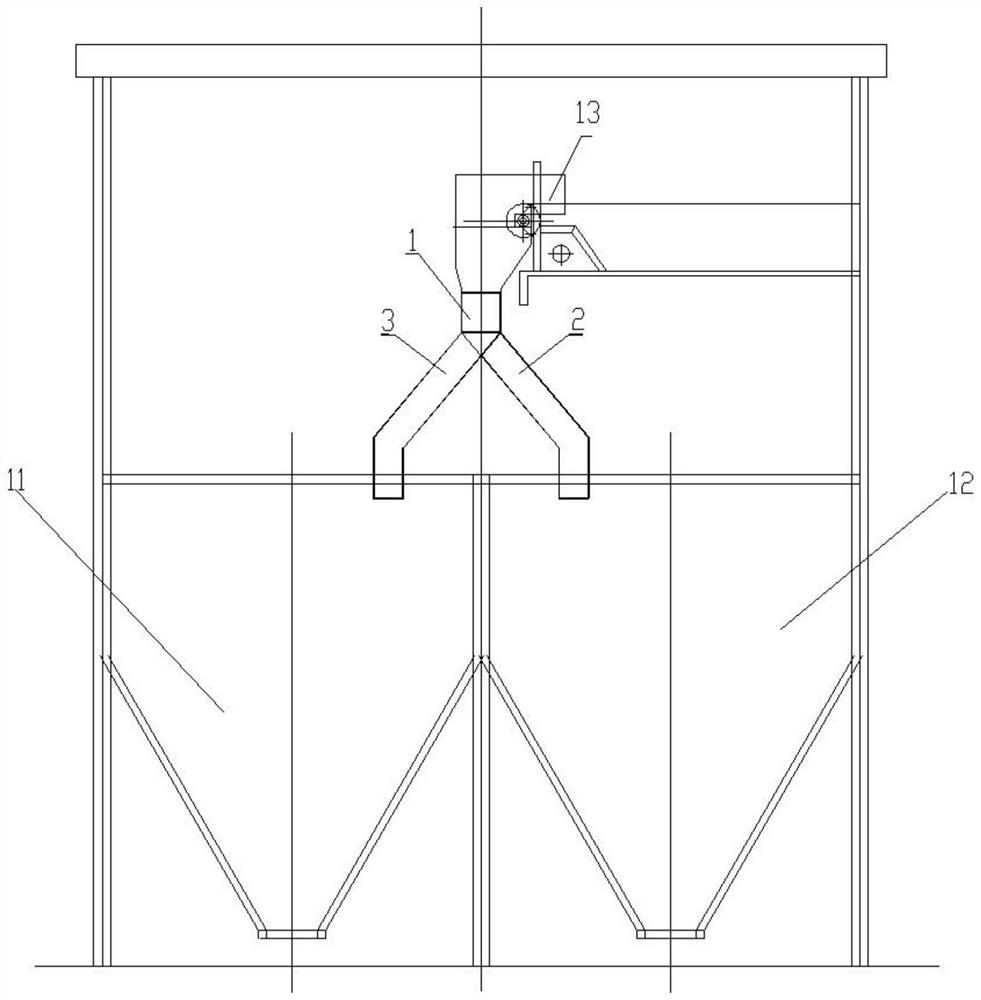

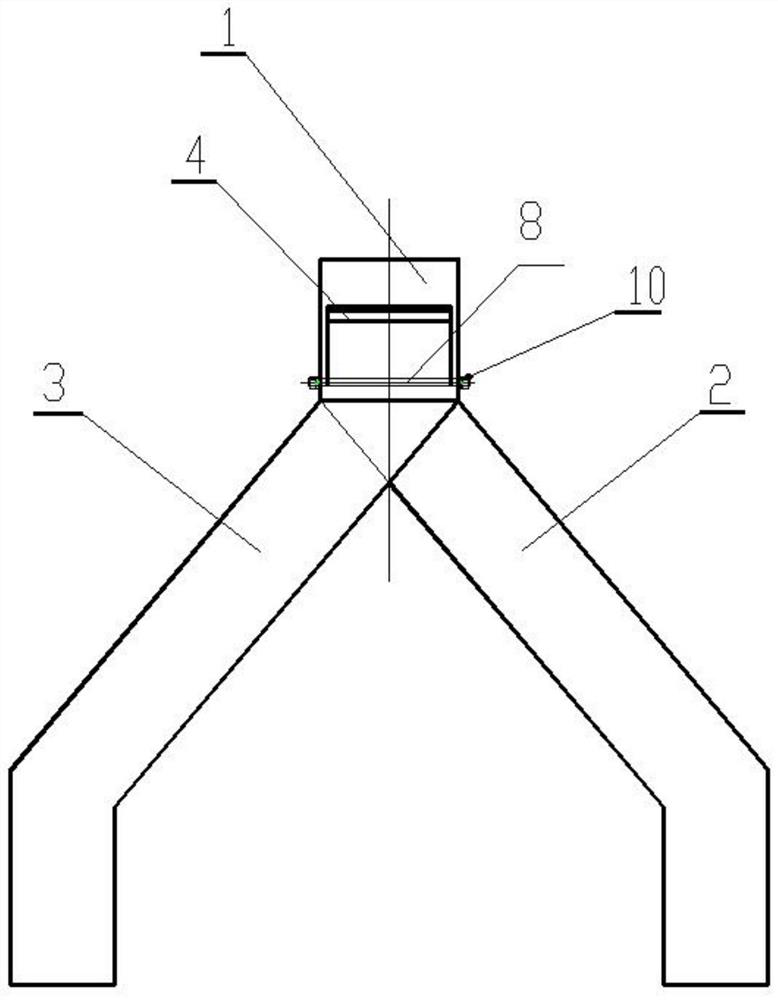

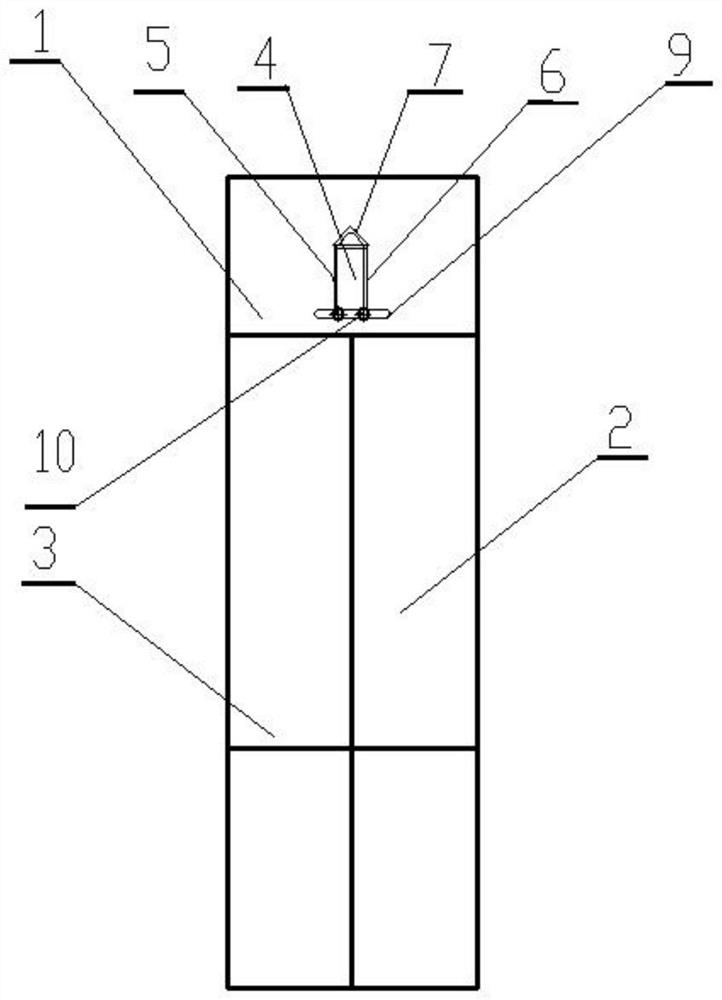

[0023] figure 1 It is a schematic structural diagram of a feed adjustment device according to Embodiment 1 of the present invention, figure 2 It is the left view of the feeding amount adjustment device according to Embodiment 1 of the present invention, image 3 It is a top view of the feed adjustment device according to Embodiment 1 of the present invention, Figure 4 It is a top view of the enlarged view of the feeding amount adjustment device according to Embodiment 2 of the present invention.

[0024] Such as figure 1 , 2 , 3, and 4, the present embodiment provides a feeding amount adjustment device, including a main feed pipe 1 and a first feed sub-pipe 2 and a second feed sub-pipe 3 connected side by side at the lower port of the feed main pipe 1. The material main pipe 1 is used to receive the material transported by the conveyor belt 13, and the first feed branch pipe 2 and the second feed branch pipe 3 are used to divide the material into two parts and feed them ...

Embodiment 2

[0031] This embodiment provides a feeding amount adjustment device. On the basis of Embodiment 1, the material distribution device 1 is not tightly connected with the feed main pipe, but the position of the material distribution device 1 is adjusted by a displacement motor so that the two materials The materials in the warehouse are equal or meet the requirements, and the position of the distributing device 1 is adjusted by the displacement motor, which is labor-saving and convenient, and improves the working efficiency.

[0032] The output shaft of the displacement motor is respectively connected with the two round steels 8 of the material distribution device 9. If the material needs to be equally divided into two feed pipes, start the moving motor to drive the round steel 8 to move, and adjust the material distribution device 1 to the middle position . If the first feed branch pipe 2 is required to feed more materials, the mobile motor can be started to drive the round steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com