Printing process of flame-retardant fabric with high content of aramid fibers

A technology of flame-retardant fabrics and high aramid fibers, applied in the field of textile printing and dyeing, to achieve the effects of improving economic benefits, reducing production costs, and solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

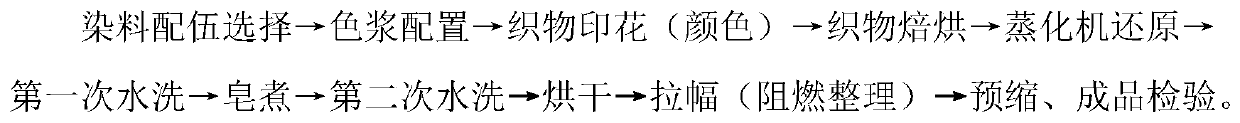

[0024] given in the present invention figure 1 In the method steps, take 14*14 flame-retardant viscose / aramid (30D) thickened woodland camouflage plaid as an example; the specific method steps are as follows:

[0025] 1. Dye compatibility selection: Through the color dithering of the laboratory sample, respectively select vat dyes, paints and auxiliary agents to configure the color paste of each color spot for printing. The selected vat dyes are: vat black GM, vat blue VB, vat red F3B, Reduced Khaki 2G, Reduced Blue CLF, Reduced Brown BR, Reduced Yellow 3RT, Reduced Olive T, Industry Olive Green B, the selected paints are: Paint Black T-**, Paint Zhangqing T-**, Paint Medium Yellow T-**, paint red T-E, paint green T-**, additives include printing super soft adhesive WH, adhesive WH-3, chemical paste KG-1, thickener KG-301 and tap water ;

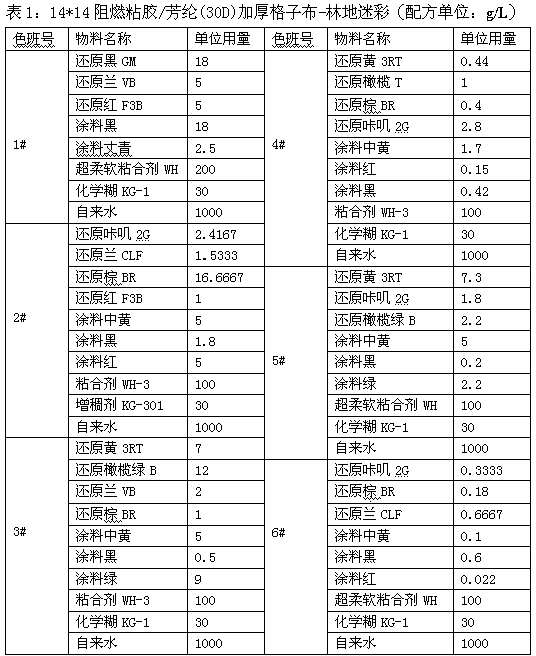

[0026] 2. See Table 1 below for the color matching formula of each color spot configured:

[0027]

[0028] 3. According to the types...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com