Ultra-short accessible type hydraulic packer

A packer, a desirable technology, applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of processing, assembly, testing, inconvenient use and transportation, difficult operation, complicated operation, etc. , to save production and later maintenance costs, facilitate transportation and use, and simplify the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

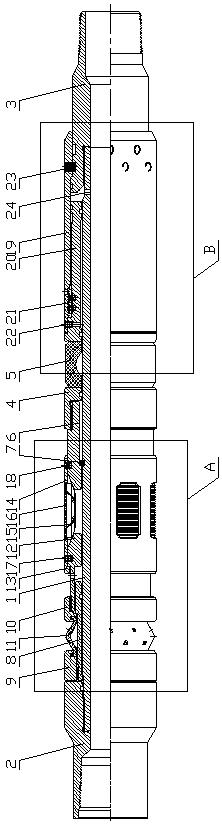

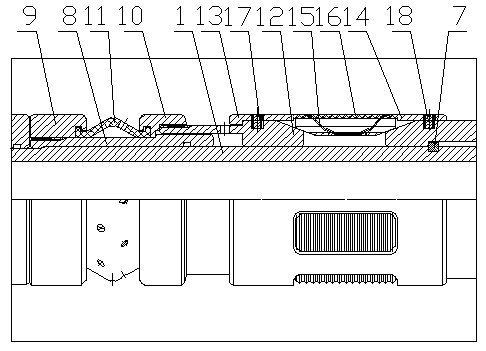

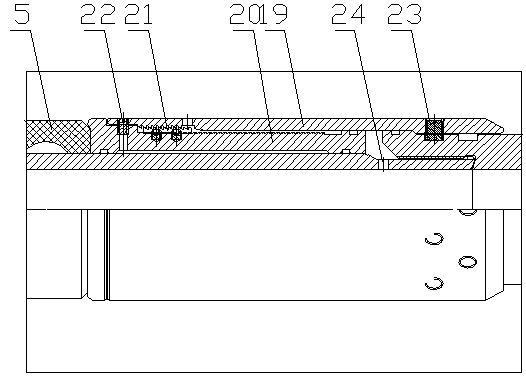

[0029] The ultra-short removable hydraulic packer includes a center pipe 1 , an upper joint 2 and a lower joint 3 , one end of the central pipe 1 is threaded with the upper joint 2 , and the other end of the central pipe 1 is threaded with the lower joint 3 . The middle part of the central tube 1 between the upper joint 2 and the lower joint 3 is installed with a rubber cylinder 5 and a lower vertebral body 6 through a guide ring 4; the guide ring 4 is connected to the rubber cylinder 5; Threaded connection, an upper limit ring 7 is arranged between the lower vertebral body 6 and the central tube 1 to limit the lower vertebral body 6 to move leftward along the central tube 1 .

[0030] The central pipe 1 on the side of the upper joint 2 is equipped with an upward moving ring 9 and a downward moving ring 10 through the connecting ring 8. The central pipe 1 is a variable diameter body. The connecting ring 8 can be axially limited by cooperating with the end surface of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com