Formation testing and sampling dual-packer

A formation testing and packer technology, applied in sealing/isolation, measurement, wellbore/well components, etc., can solve the problems of high testing cost, small pressure testing and sampling area, formation pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the structure and advantages of the double packer of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings. It should be pointed out that the implemented schemes and features of the present invention are not limited to the present invention, and any modifications and changes in specific implementations by those skilled in the art are still within the protection scope of the patent of the present invention.

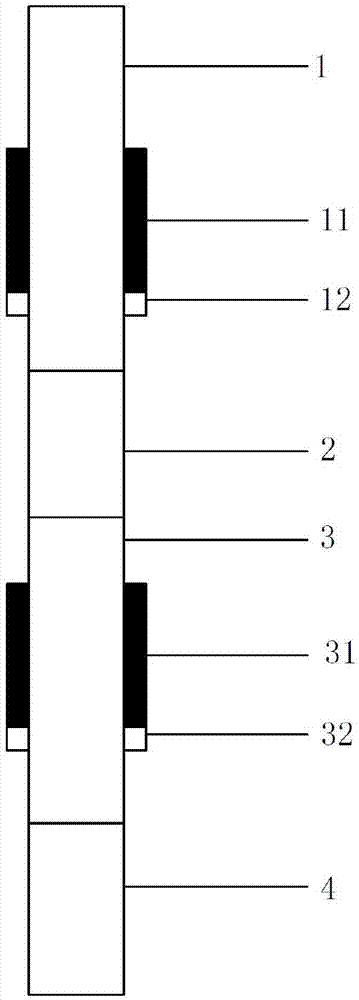

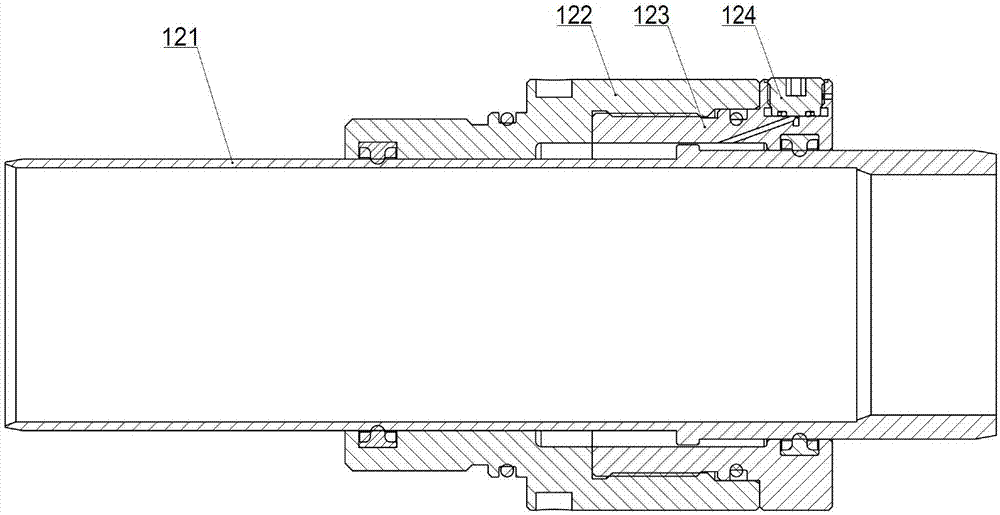

[0021] Such as figure 1 As shown, the double packer for formation testing and sampling of the present invention mainly includes: a first packer 1, an automatic recovery arm 12, a spacer nipple (optional) 2, a second packer 3, an automatic recovery arm 32, a hydraulic control paragraph 4.

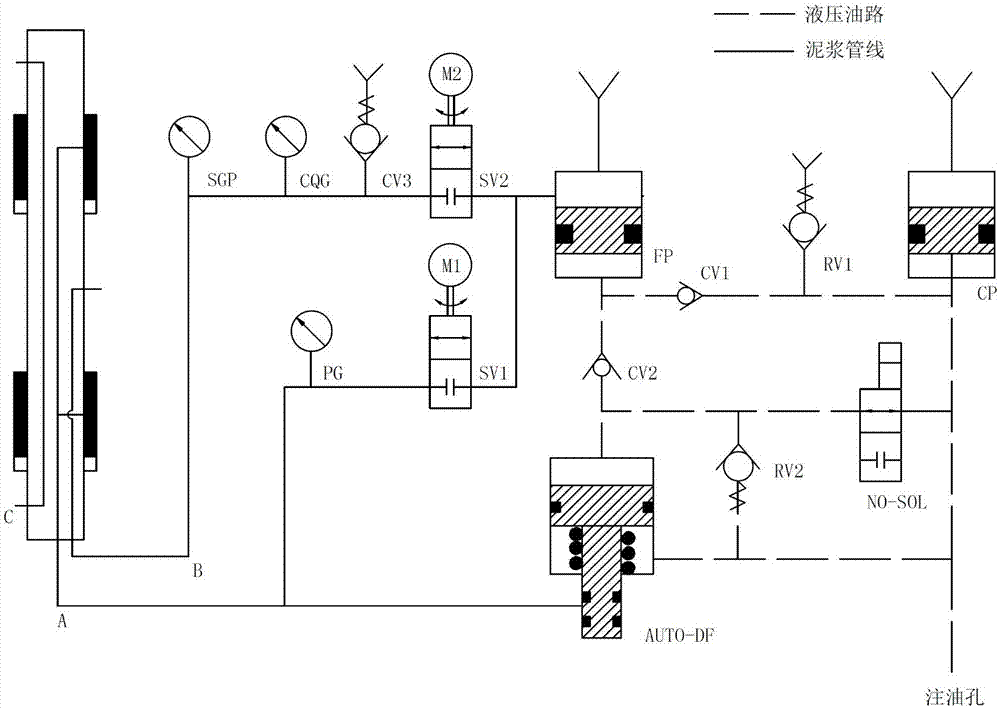

[0022] The first packer 1 is equipped with an expandable packer rubber tube 11, and an expansion line A for expanding the rubber tube is arranged inside, and a bypass for balancing the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com