Motor vehicle-tank assembly having filter body that enhances withdrawal reliability, and such filter body

A filter, motor vehicle technology, applied in the direction of fixed filter element filter, filtration separation, vehicle parts, etc., can solve the problem of not being able to continuously guarantee extraction and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

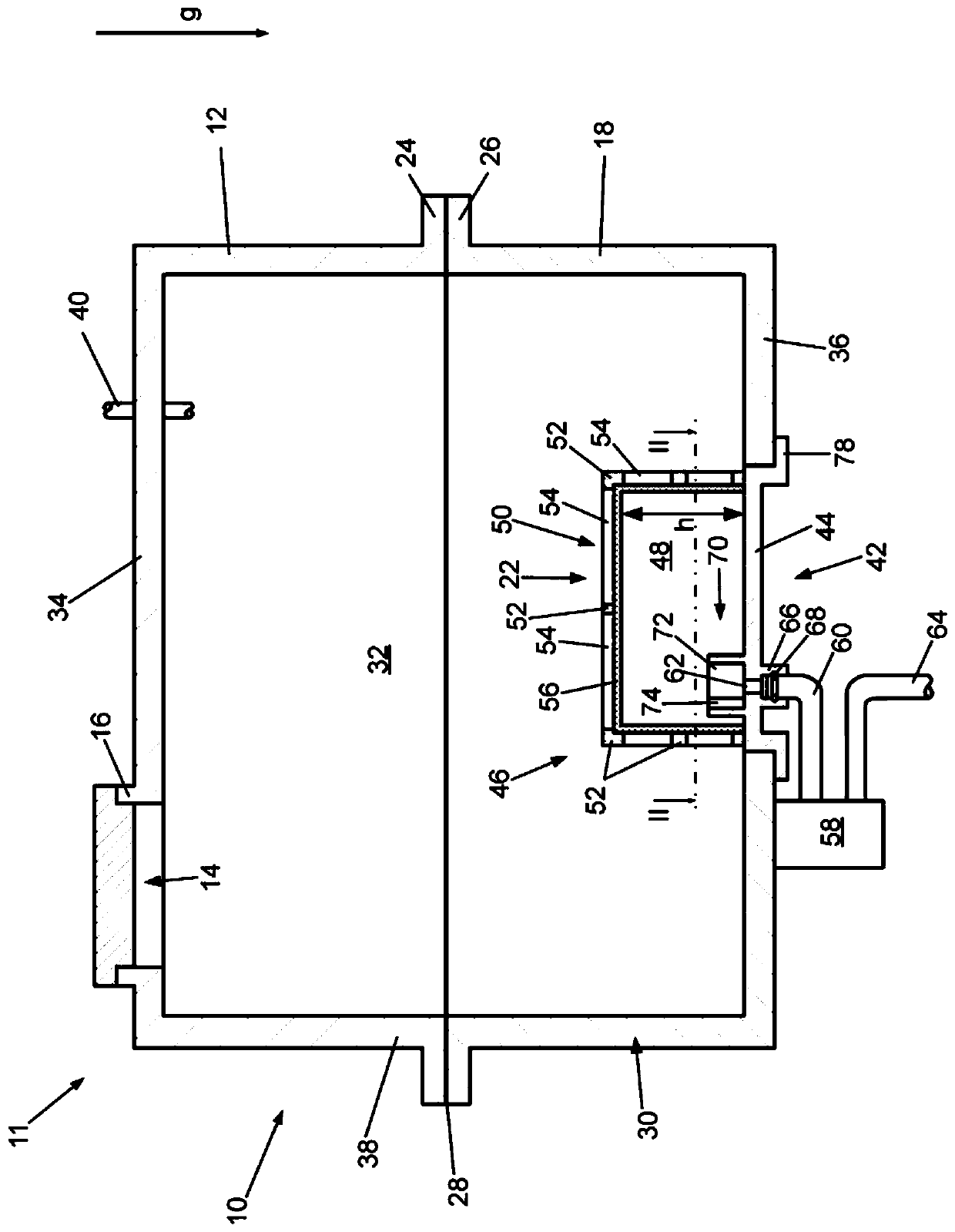

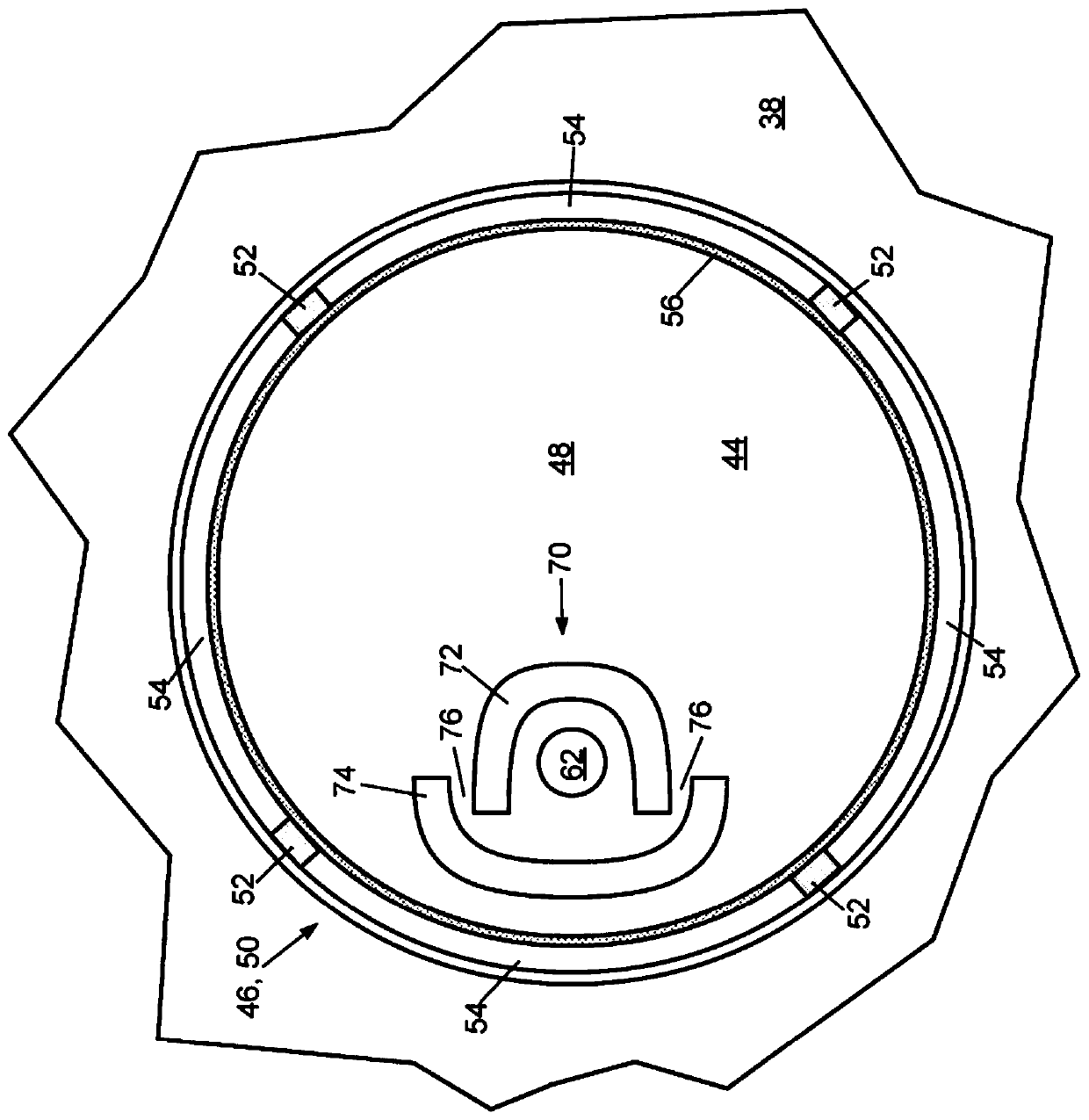

[0034] exist figure 1 Here, the liquid tank of the motor vehicle-tank assembly 11 according to the present invention is denoted as a whole by 10 . The liquid tank 10 preferably includes an upper shell part 12 having a filling opening 14 with a flanged edge 16 surrounding the filling opening 14 . A filling line can be connected to the flange edge 16, e.g. figure 1 Fill tube not shown. The filling opening 14 , or if a filling line is present, can preferably be closed by a cover 17 .

[0035] The liquid tank 10 also includes a lower housing part 18 which has a mounting opening 20 with a filter body 22 which is inserted into the mounting opening 20 and closes it.

[0036] The upper shell part 12 and the lower shell part 18 are preferably joined to each other, eg glued or welded, along respective circumferential joint flanges 24 and 26 . Joint flanges 24 and 26 meet along joint surface 28, which is preferably planar.

[0037] The tank 10 has a tank shell 30 which encloses a ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com