Device and method for cutting the pile yarns to be woven in an axminster weaving machine

A cutting device and yarn technology, applied in the direction of looms, flannelette looms, textiles and papermaking, etc., to achieve the effects of eliminating regrinding costs and use costs, uniform pile surface, and good cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

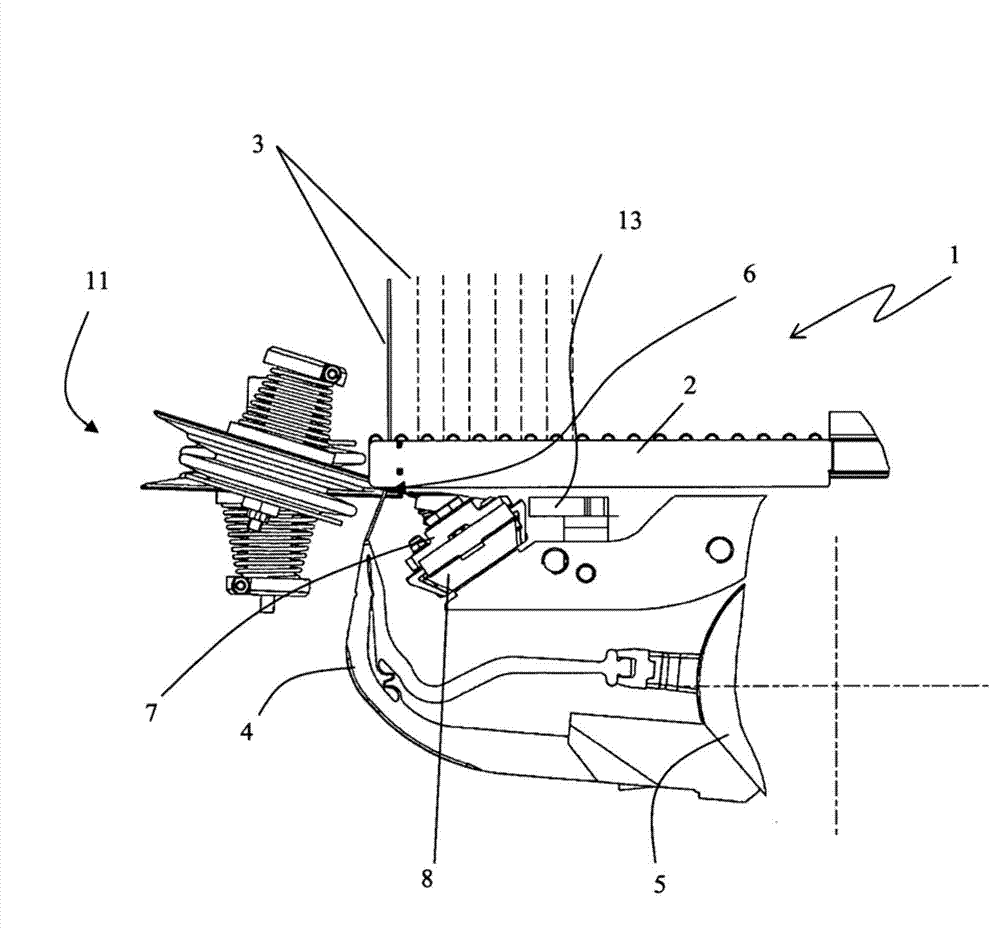

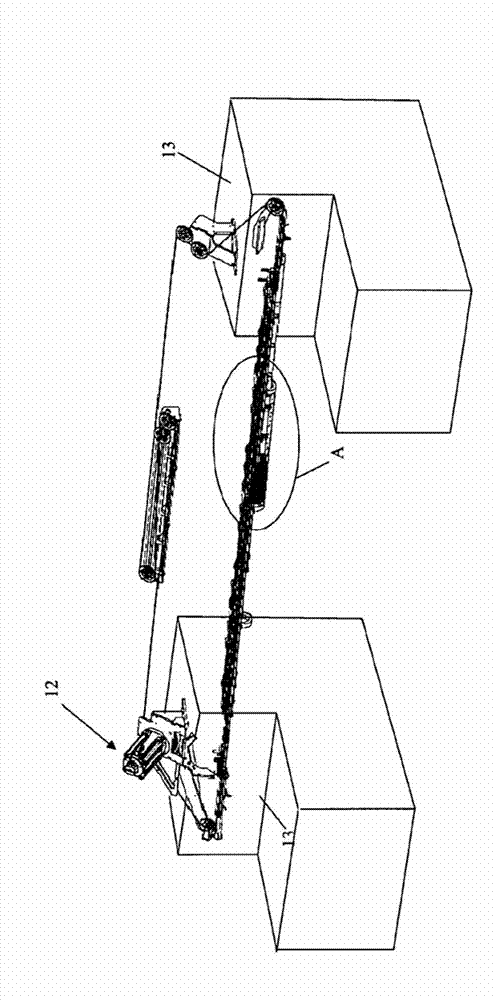

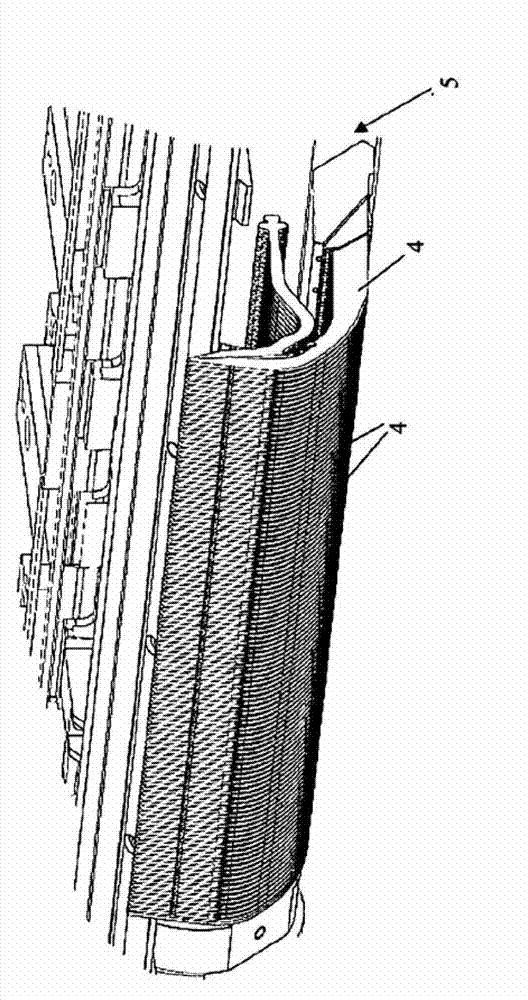

[0043] The invention concerns the removal of pile yarns from a pile yarn selection system 1 provided with a pile yarn selection system 1 (see figure 1 Pile yarn stock cut-off on Axminster (Axminster) loom of ), wherein pile yarn loader 2 is controlled to provide pile yarn 3 to pile yarn gripper 4, so The pile yarn gripper 4 is arranged on the gripper bar 5 and grips selected pile yarns to draw them to the pile yarn loader over the entire tuft length according to the fabric to be manufactured. outside. Preferably, the pile yarn 3 is cut by means of a single cutting blade 6 moving at least across the entire weaving width.

[0044] The cutting blade 6 is arranged on cutting means, such as a blade carriage 7 moving along one or more guide means 8 . In one movement, the blade 6 cuts off all the yarns that have been gripped by the pile yarn gripper and pulls them out of the pile yarn loader according to the desired tuft length. This is necessary because the cut pile yarns are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com