Low-strain measurement device for fixed pile foundation with grasping pile

A fixed, positioning device technology, used in infrastructure engineering, infrastructure testing, analysis of solids using sonic/ultrasonic/infrasonic waves, etc. Achieving good fixing effect and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

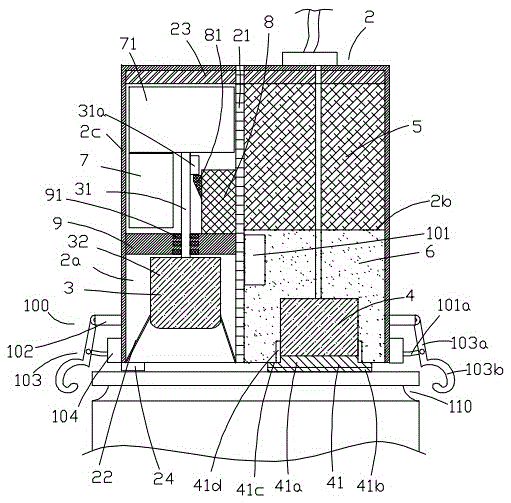

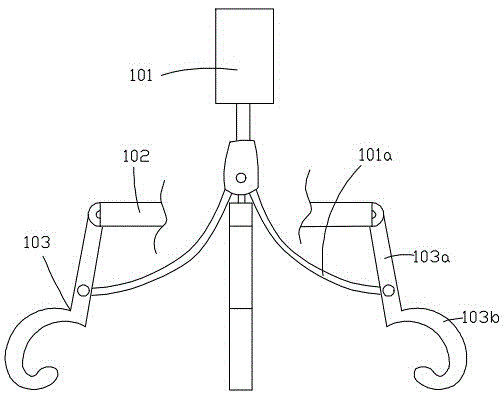

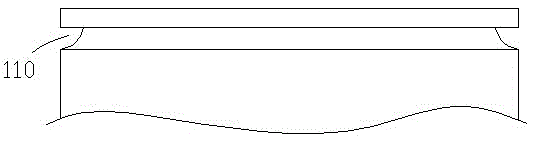

[0025] Figure 1 to Figure 7 Shown is the structural representation of the present invention.

[0026] The reference signs are: data processor 1, controller 11, stress wave generating and receiving device 2, left cavity 2a, right cavity 2b, housing 2c, waterproof interlayer 21, flexible water-proof membrane 22, glue layer 23. Balance foot 24, hammer 3, hammer handle 31, clamping block 31a, hammer head 32, stress wave receiving probe 4, pressure isolation block 41, pressure isolation hard layer 41a, adhesive glue layer 41b, sealing shoulder 41c, sealing ring 41d, counterweight 5, damping layer 6, driving motor 7, cylinder 71, gear block 8, locking protrusion 81, sealing flange 9, sealing floating ring 91, positioning device 100, push-pull motor 101 , a push-pull rope 101a, a protruding rod 102, a pile grabber 103, a grabbing rod 103a, a hook 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com