Intelligent traction moving plate applied to erecting power transmission line

A power transmission line, intelligent technology, applied in the direction of overhead line/cable equipment, etc., can solve the problem of inconvenient use of running boards, and achieve the effect of saving space, convenient use, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

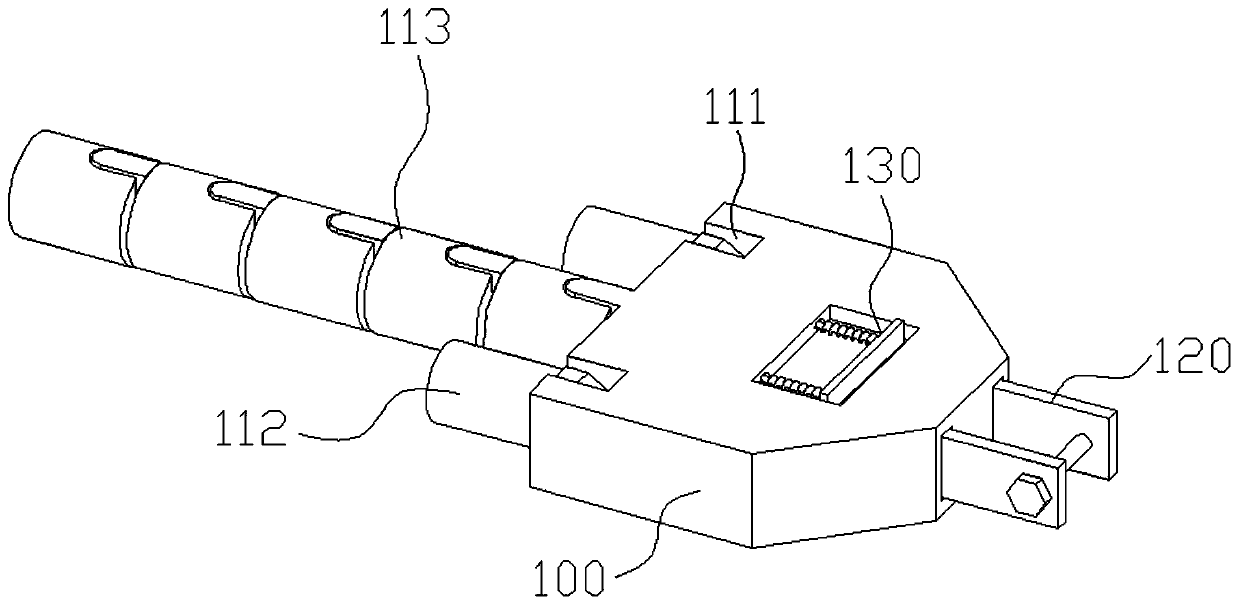

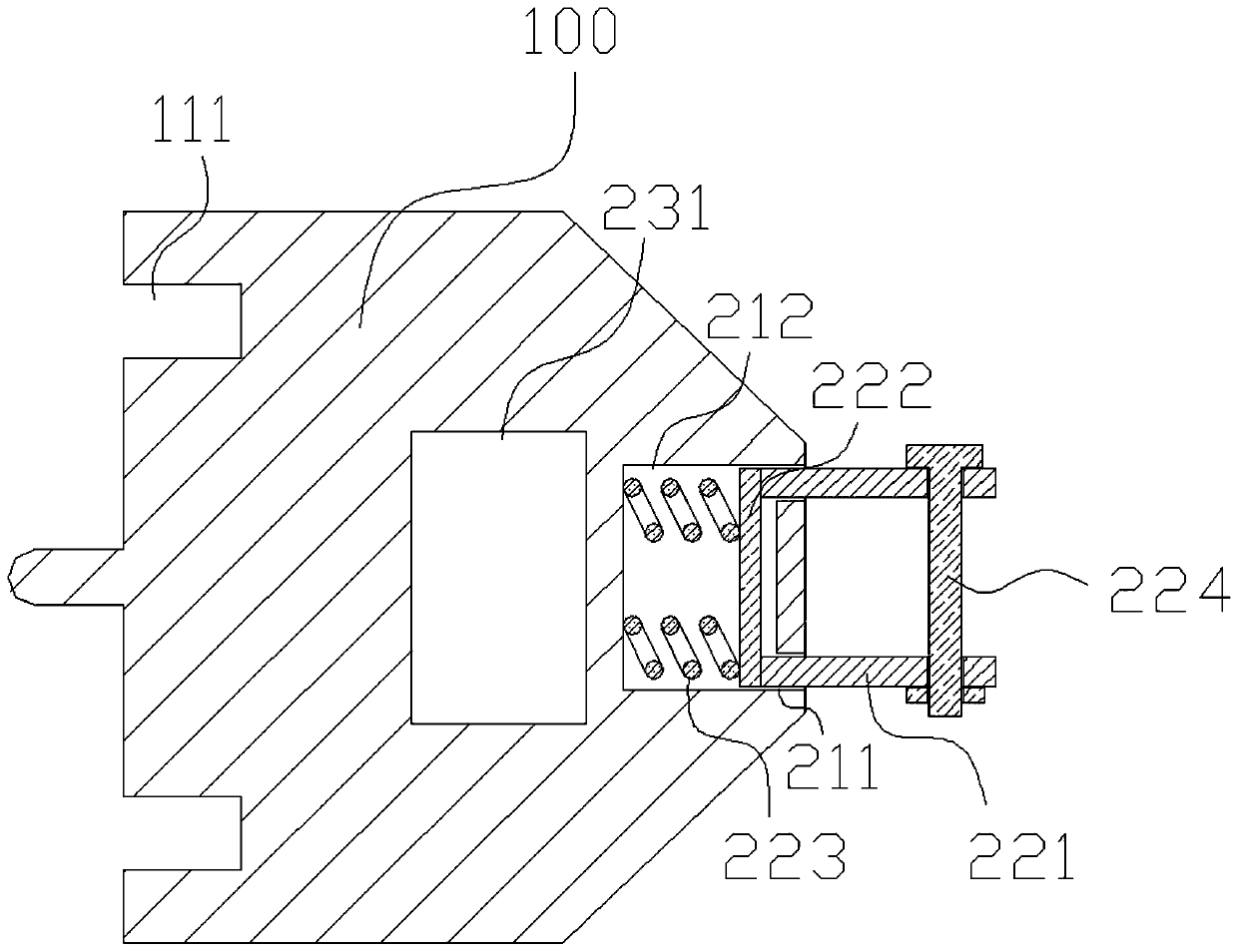

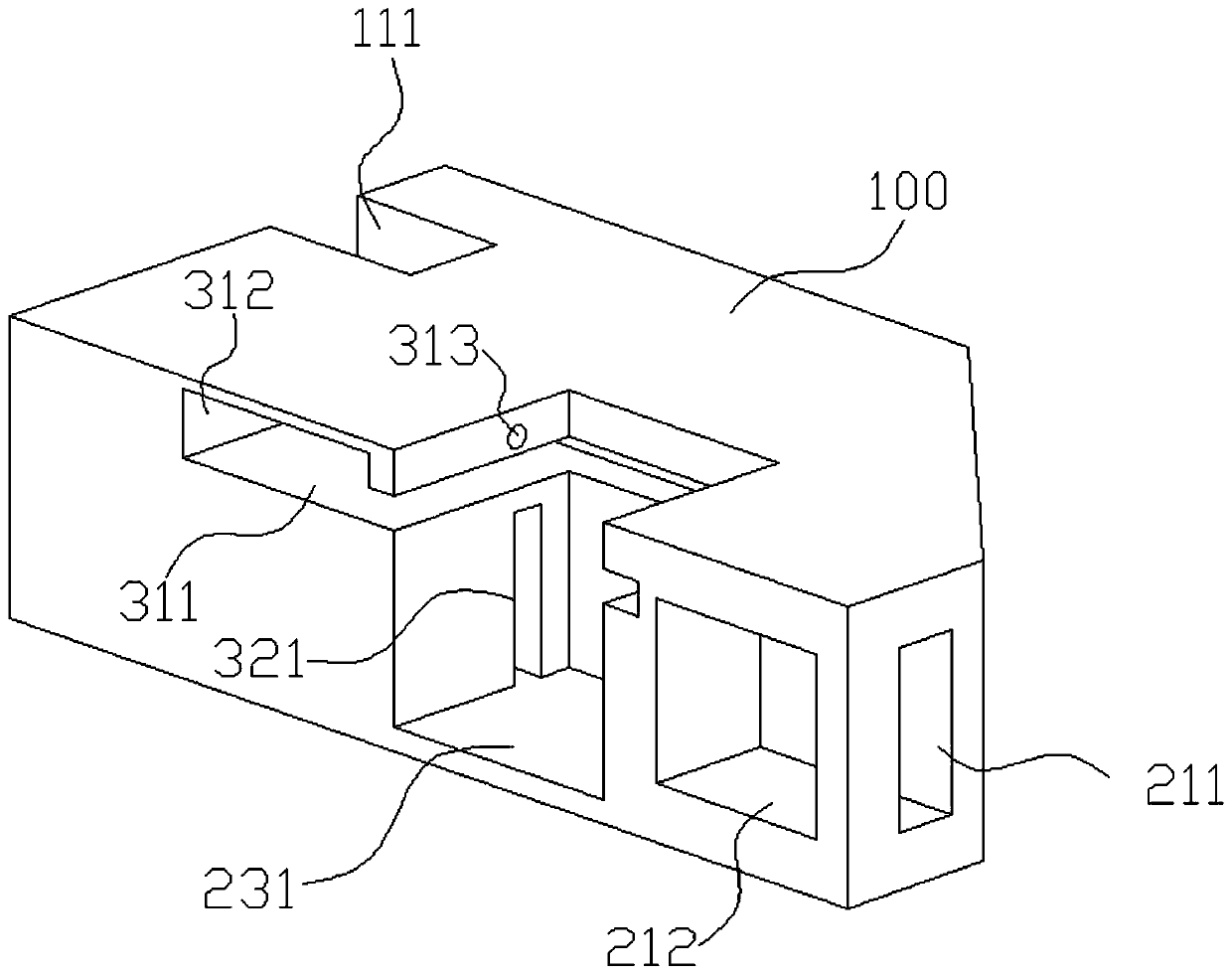

[0035] Such as Figure 1-8 As shown, this embodiment provides an intelligent traction walking board applied to erecting power transmission lines, which includes a walking board main body 100, and the left side of the walking board main body 100 is provided with snap-in slots 111 at the front and rear ends. A rotary connector 112 for connecting wires is hinged in the clamping groove 111. The right side of the walking board main body 100 and located at the front and rear ends are provided with movable grooves 211 along the left and right directions, and the walking board main body 100 is provided with communicating movable grooves The cavity 212 of 211; the right side of the walking plate main body 100 is provided with a traction mechanism 120 for connecting the traction line, the traction mechanism 120 includes a movable plate 221 located in the corresponding movable groove 211, and a movable plate 221 is connected between the movable plates 221 and is located in the cavity. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com