Modular street lamp

A technology for street lamps and lamp holders, applied in the field of modular street lamps, which can solve problems such as high power consumption, low service life of street lamps, and burnt substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

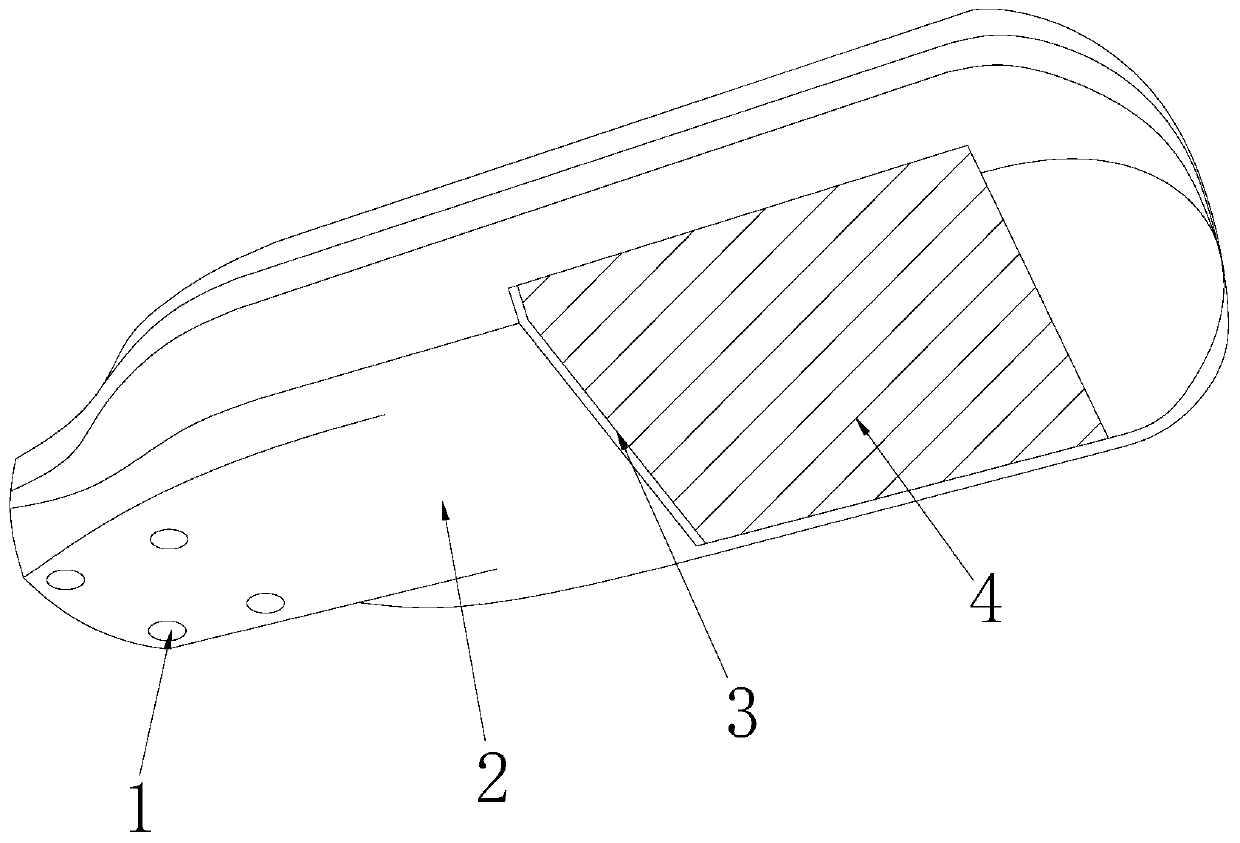

[0025] see Figure 1-Figure 7 , the present invention provides a modular street lamp, the structure of which includes a mounting hole 1, a lamp cap 2, a composite lighting fixture 3, and a light-transmitting plate 4. There are four mounting holes 1, and the mounting hole 1 is installed on the working lamp cap 2 away from At the position of the light-transmitting plate 4, the mounting hole 1 penetrates the lamp holder 2, the light-transmitting plate 4 is rectangular, and a composite lighting fixture 3 is arranged inside the light-transmitting plate 4, and the composite lighting fixture 3 is installed on Inside the lamp holder 2;

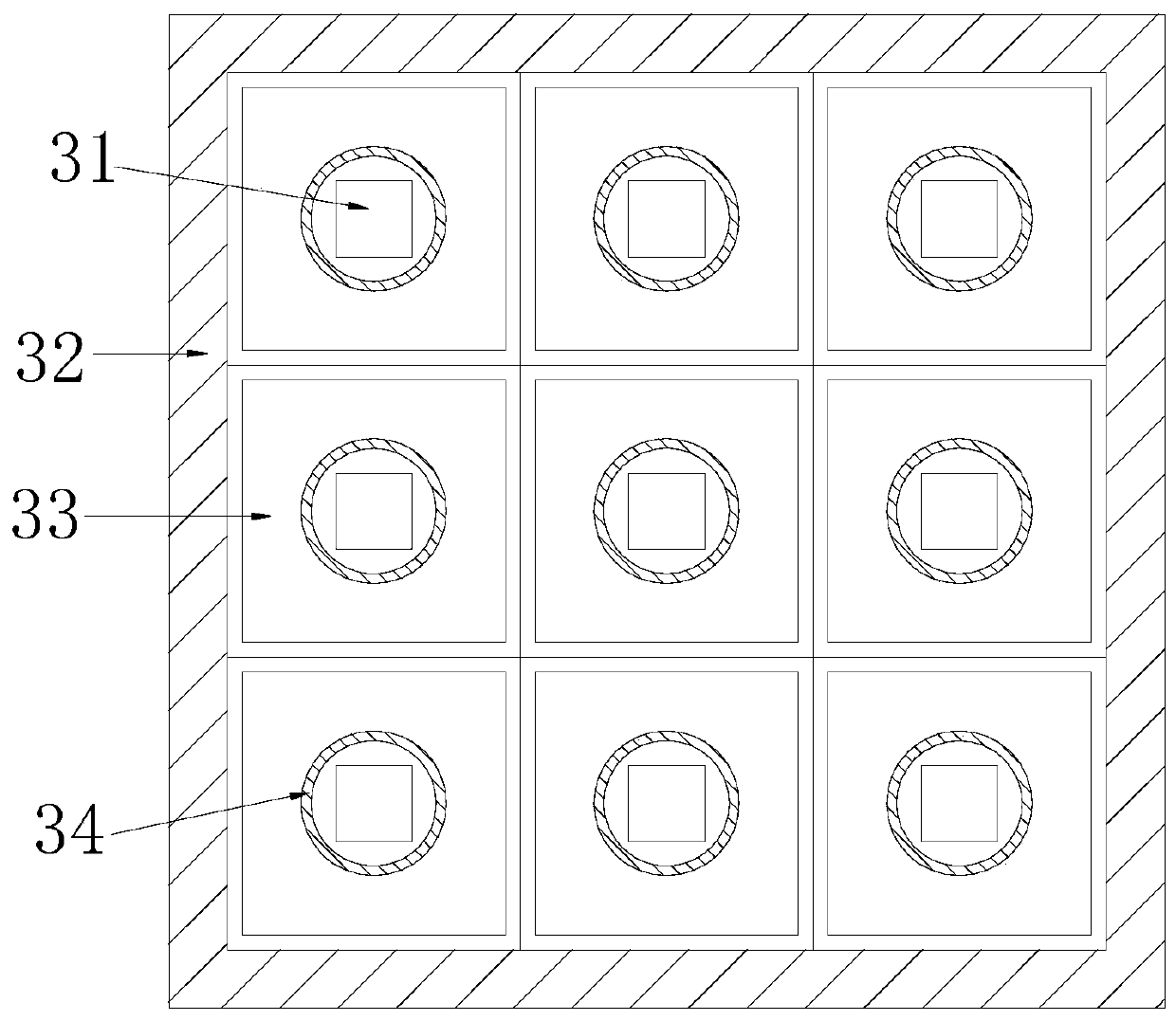

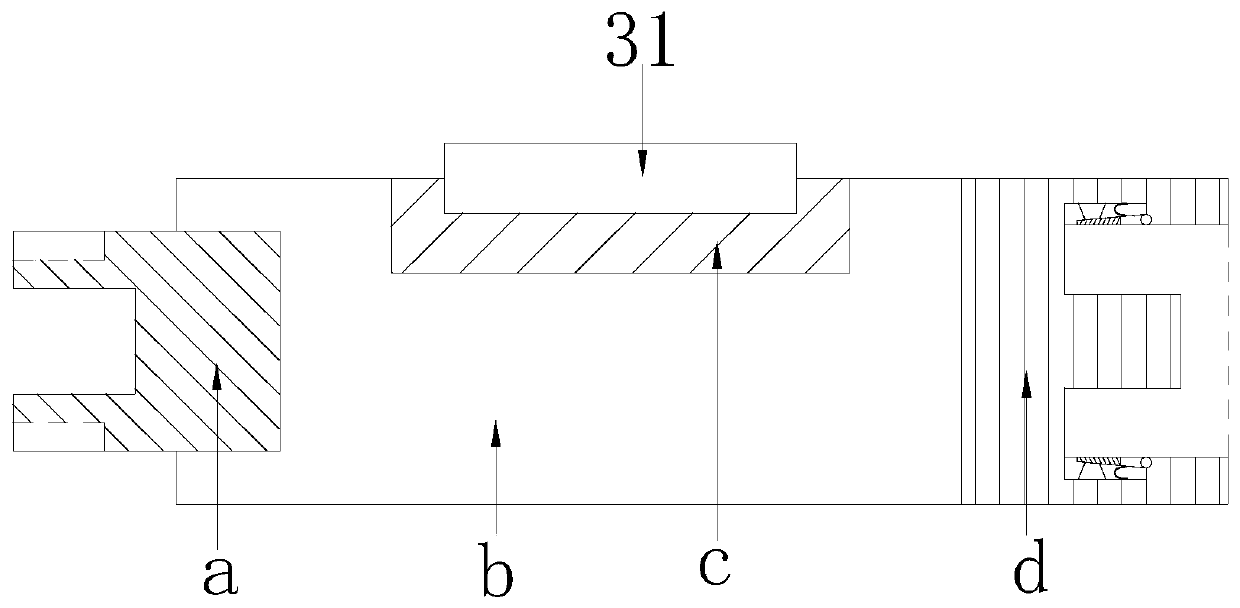

[0026] The composite lighting fixture 3 is composed of a lamp bead 31, a substrate installation groove 32, a composite substrate 33, and a lamp bead installation groove 34. The lamp bead 31 is installed in the lamp bead installation groove 34, and the lamp bead installation groove 34 is circular. Shape, the lamp bead installation groove 34 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com