Tire scanning detection system and tire scanning detection data integration acquisition method

A detection system and tire technology, applied in the direction of conveyor control devices, instruments, conveyors, etc., can solve the problems of unfavorable tire quality control, many operators, low production efficiency, etc., to solve the shortage of production space and improve the specification range , reduce the effect of the station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment the preparation method of the present invention is further described:

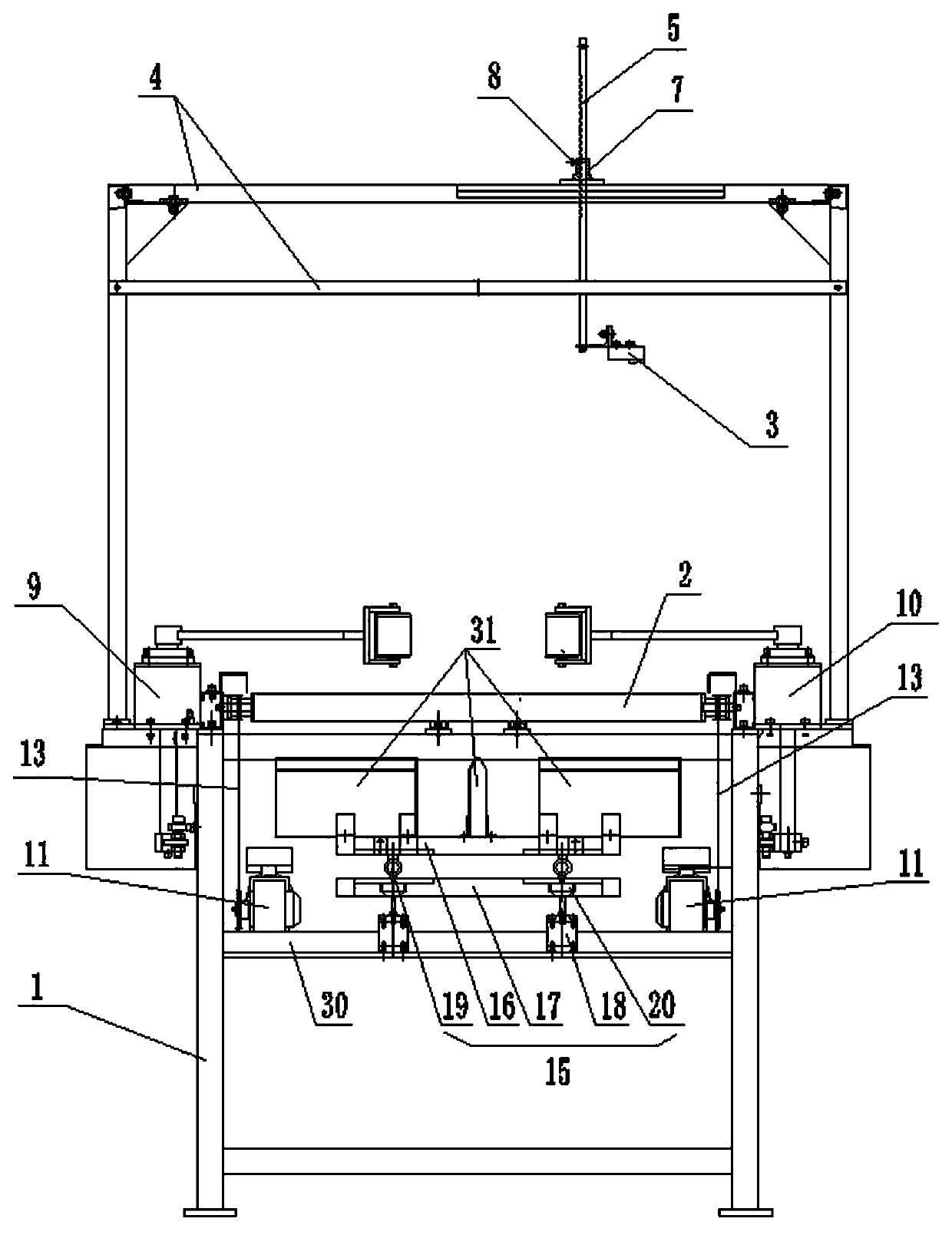

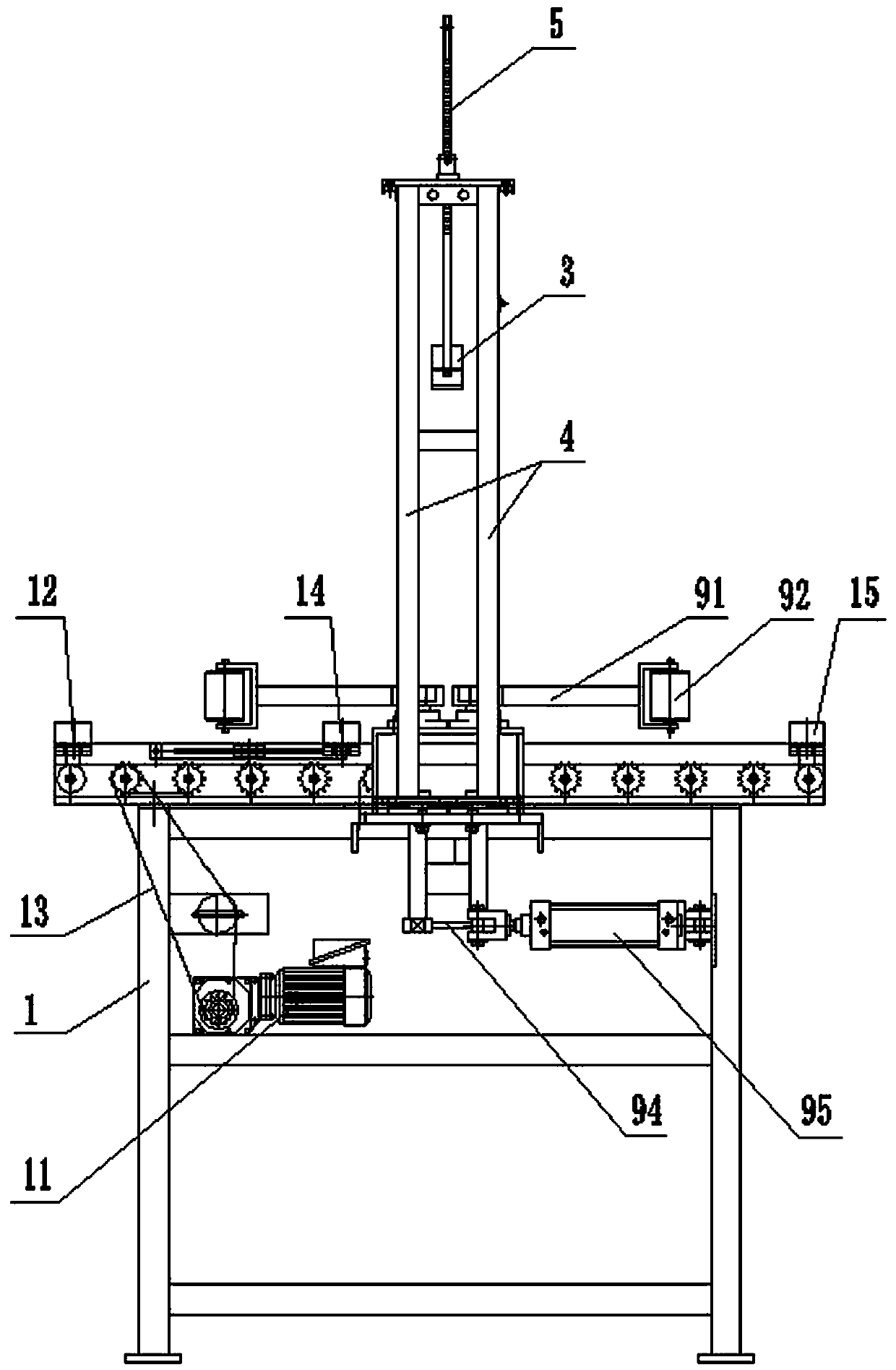

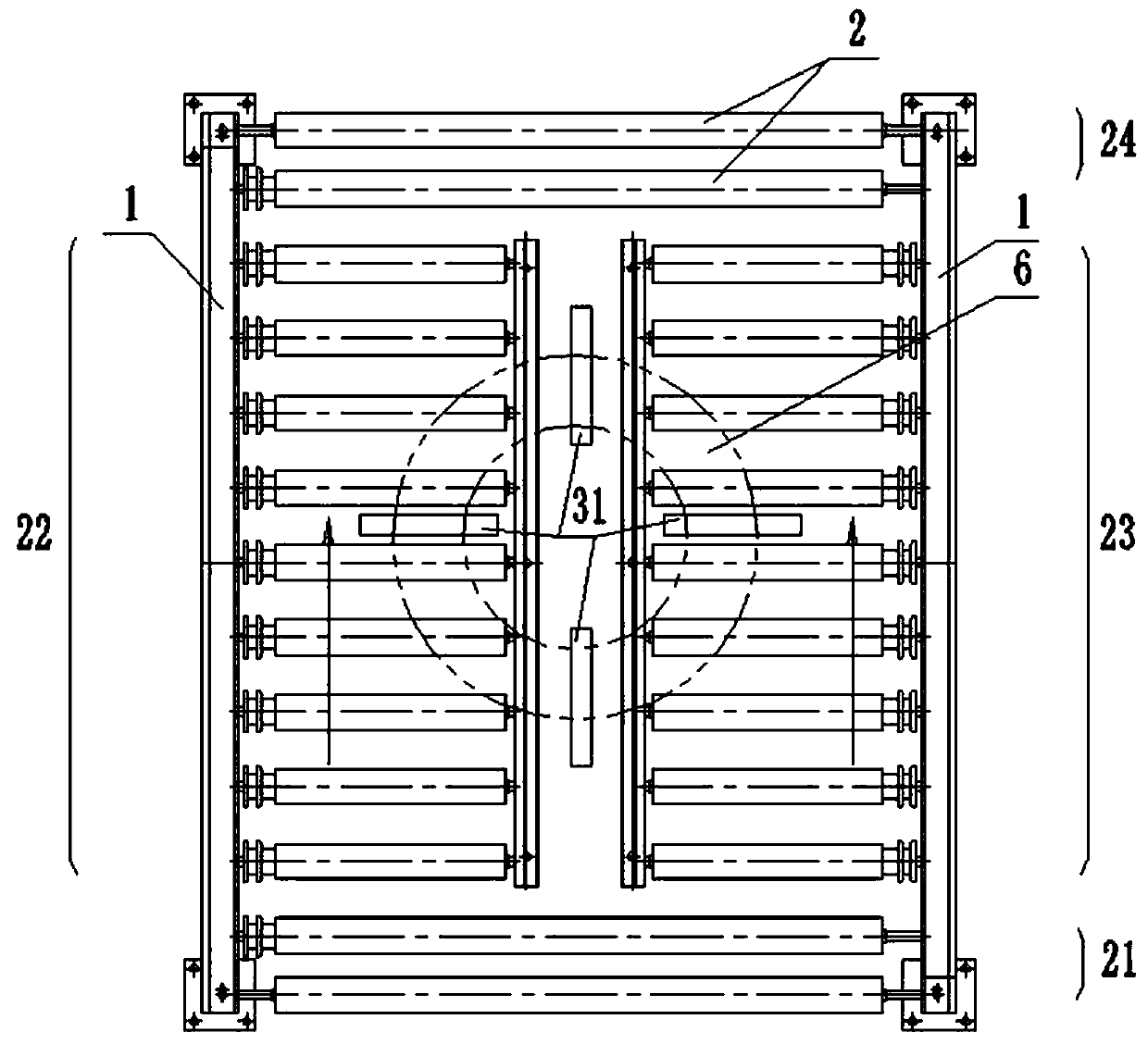

[0035] See figure 1 , figure 2, is a structural schematic diagram of an embodiment of the tire tracking detection system of the present invention, including a main frame 1, a conveying roller 2, a lifting driver 18, a load cell 19, a tire positioning frame 31, a code scanner 3, a code scanner bracket 4 and A controller (not shown), a number of conveying rollers 2 are arranged on the main frame 1, and the conveying rollers 2 are driven by a conveying roller motor 11 and a chain 13, and the code scanner bracket 4 is vertically centered on the main frame 1. A lifting rod 5 is provided between the bracket 4 and the code scanner 3, and the position of the lifting rod 5 relative to the code scanner bracket 4 can be adjusted in both horizontal and vertical dimensions. The code scanner 3 is located above the conveying roller 2 for The tire 6 on the delivery roller sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com