Method for predicting spontaneous combustion danger in gas extraction boreholes

A prediction method and gas drainage technology, which is applied in the direction of gas discharge, mining equipment, mining equipment, etc., can solve problems such as difficult to determine the weight of evaluation indicators, scrapping of boreholes, spontaneous combustion of boreholes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

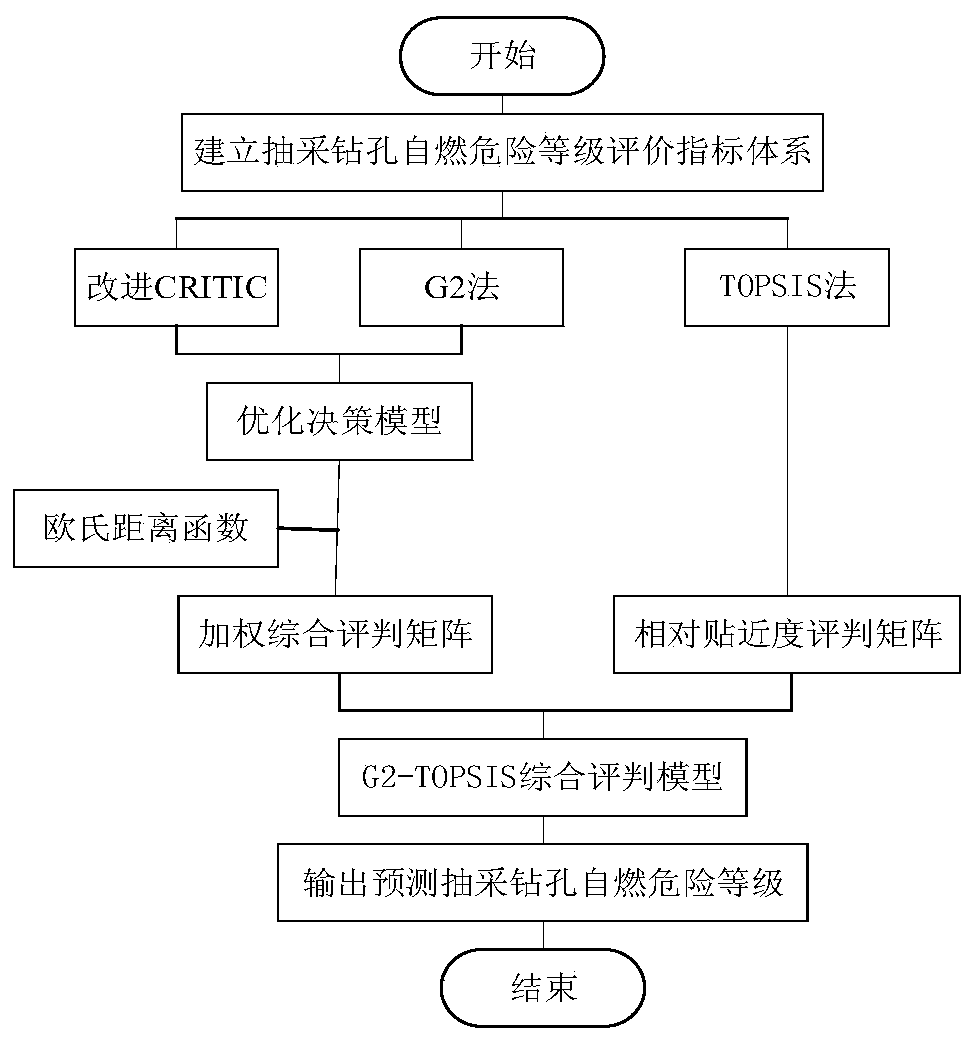

[0058] A method for predicting the risk of spontaneous combustion in gas drainage boreholes, such as figure 1 shown, including the following steps:

[0059] Step 1: The individual indicators of the spontaneous combustion hazard of the test point are the degree of coal carbonization and deterioration, the temperature difference between the redox ignition point of coal, the oxygen absorption capacity of coal, the unit temperature rise rate of CO, the geological structure, the buried depth of the coal seam, the thickness of the coal seam, the inclination angle of the coal seam, the intensity of air leakage, and the air leakage Duration, surrounding rock temperature, sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com