Multi-stage pump middle section double-impeller slope flow channel

A double-impeller, multi-stage pump technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of small flow and low power, and achieve the effect of increasing kinetic energy and improving water delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

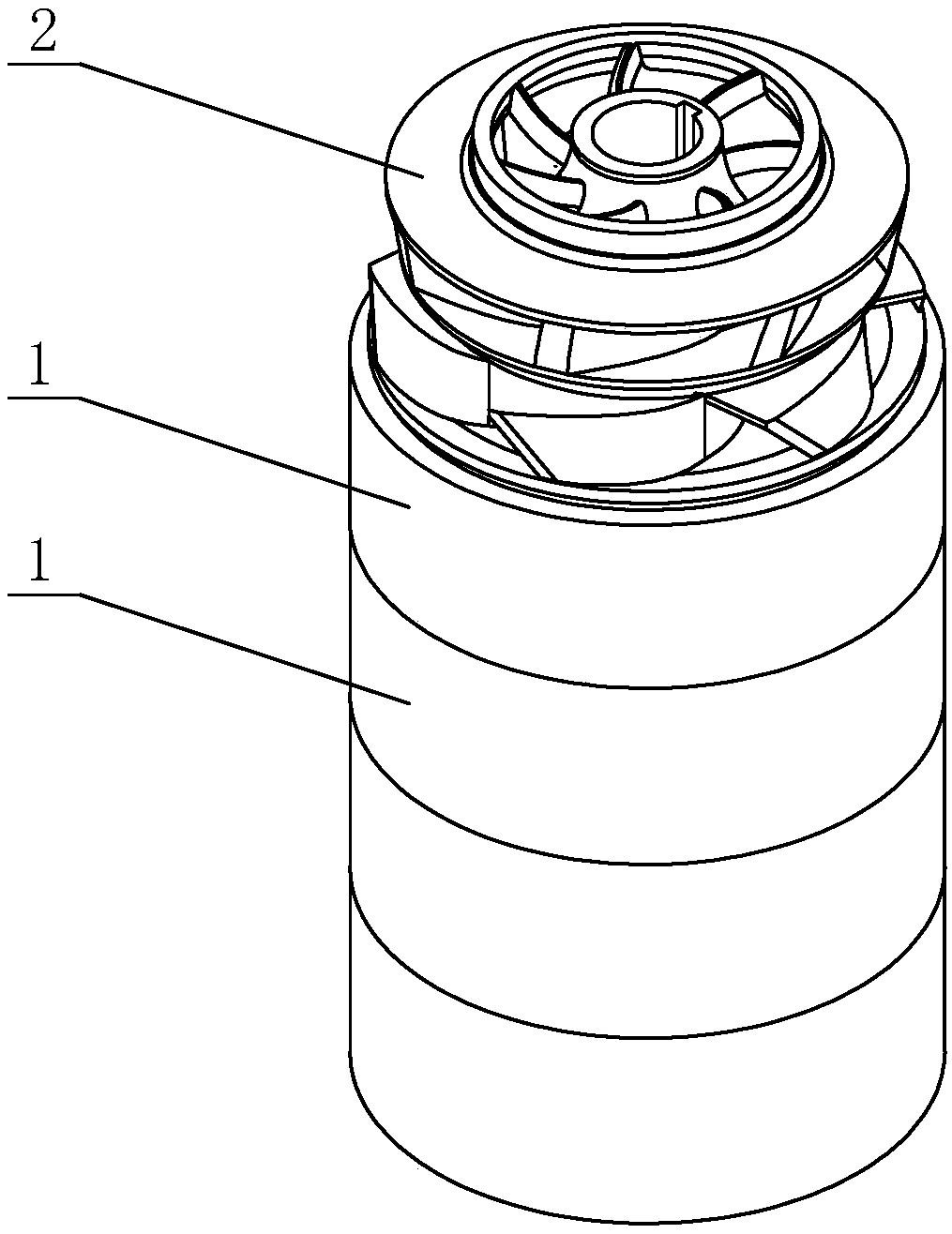

[0040] Such as figure 1 As shown, the double-impeller slope flow channel in the middle section of the multi-stage pump includes a plurality of water guide assemblies that are plugged and matched with each other. In use, the impeller rotates so that the water flows in one direction through the plurality of mid-section guide vanes, thereby pumping the water.

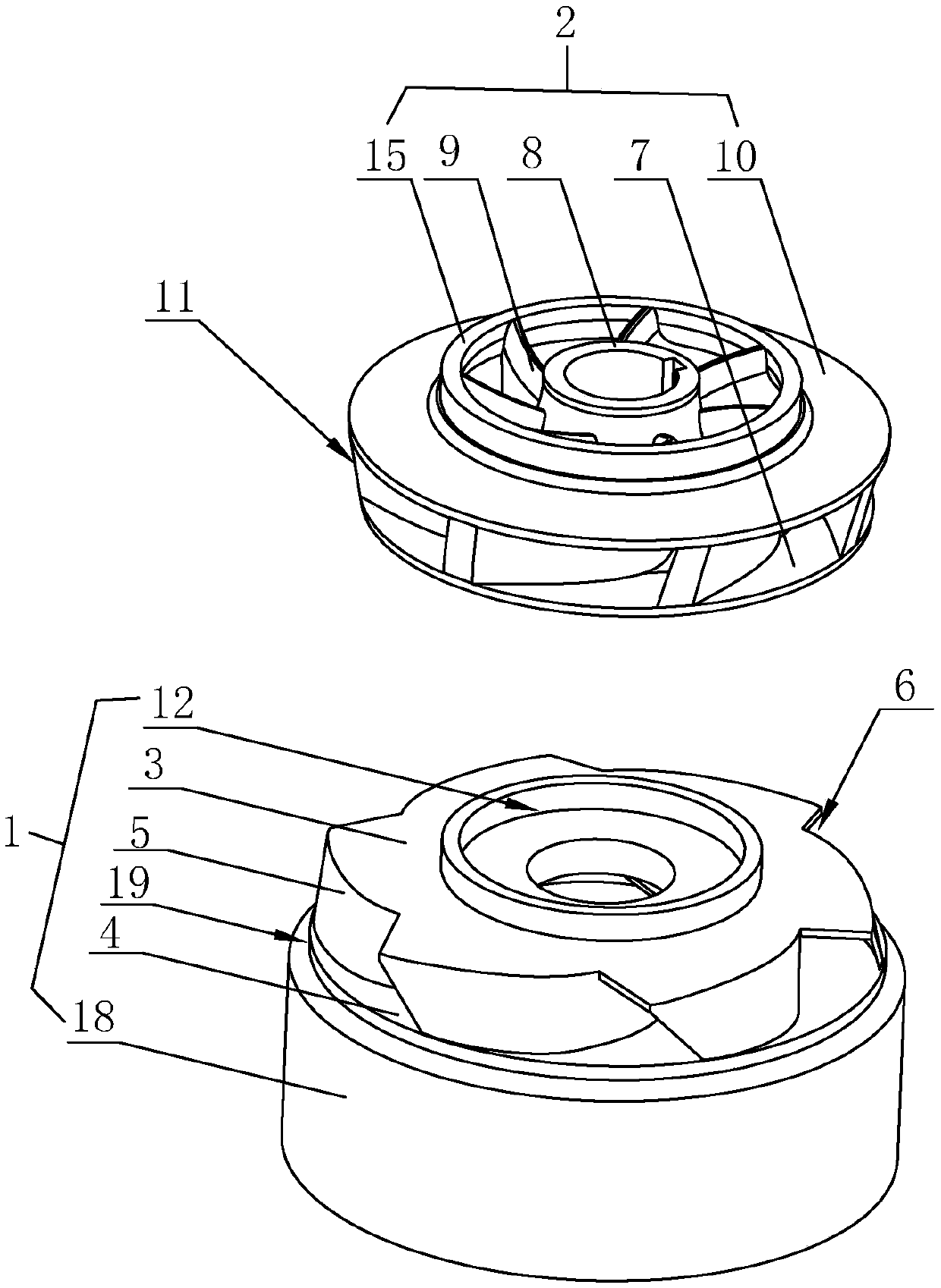

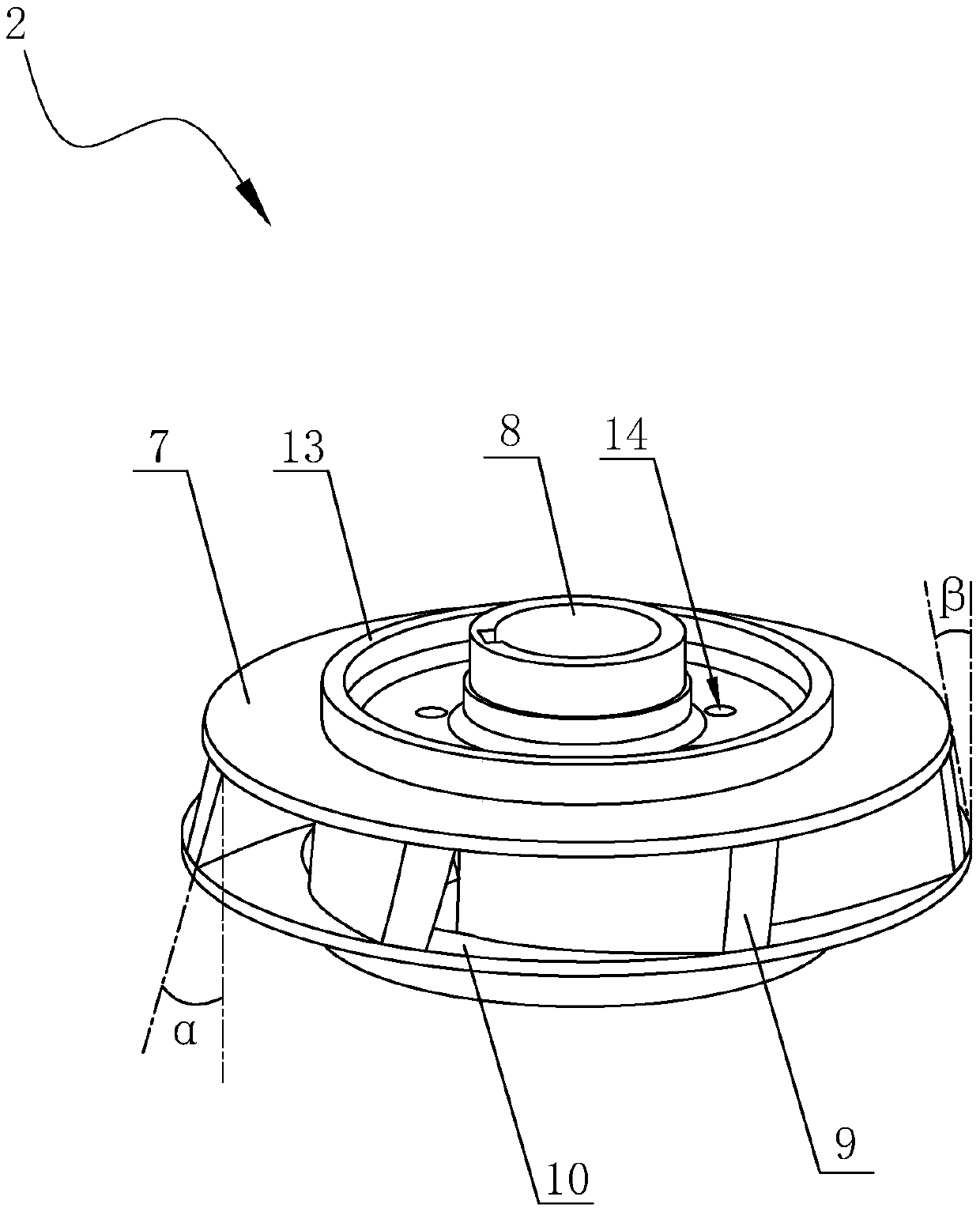

[0041] Such as figure 2 and Figure 4 As shown, the middle guide vane includes a front cover plate and a rear cover plate with circular surfaces, and a plurality of guide vanes are fixed in a spiral shape between the front cover plate and the rear cover plate, and the guide vanes are obliquely fixed on the front cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com