System and method for monitoring leakage of non-metal pipeline

A pipeline leakage, non-metallic technology, applied in the pipeline system, by detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of fast sound wave attenuation, large noise interference, and lack of leakage Monitoring technology and other issues, to achieve the effect of easy implementation, simple detection equipment, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

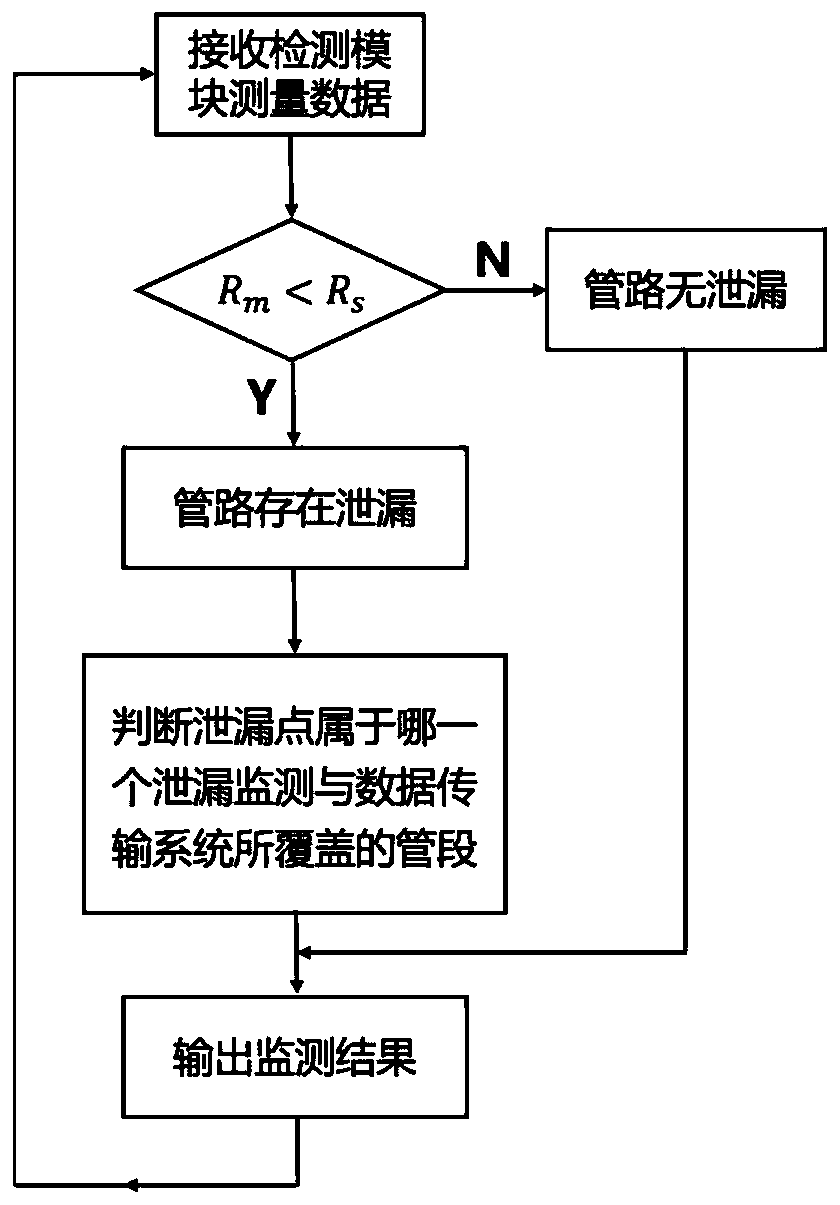

[0056] This implementation case implements monitoring according to the following steps:

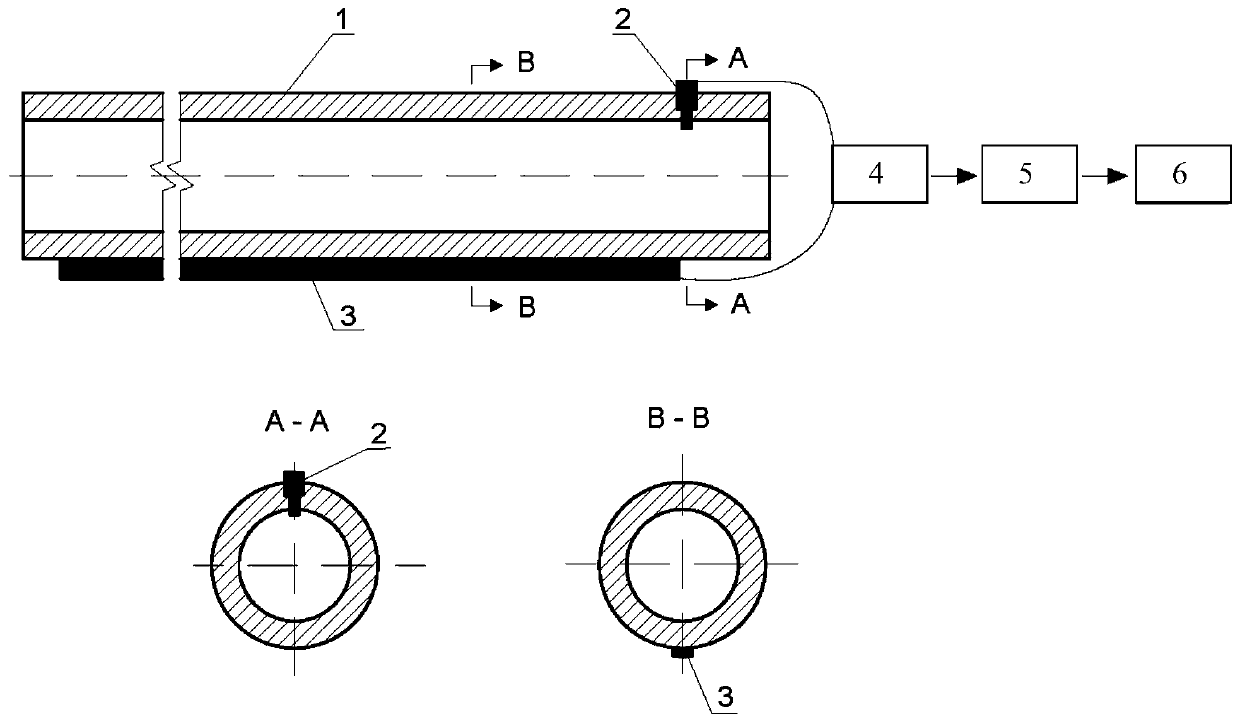

[0057] (1) According to figure 1 The monitoring electrodes and multimeters are arranged as shown, and the filling medium in the pipeline is water;

[0058] (2) When there is no leakage in the pipeline, use a multimeter (maximum measurement resistance 200MΩ) to measure the resistance value between the axial monitoring electrode 3 and the circumferential monitoring electrode 2. The measurement result shows that the resistance value exceeds the range, which is recorded as R 0 ;

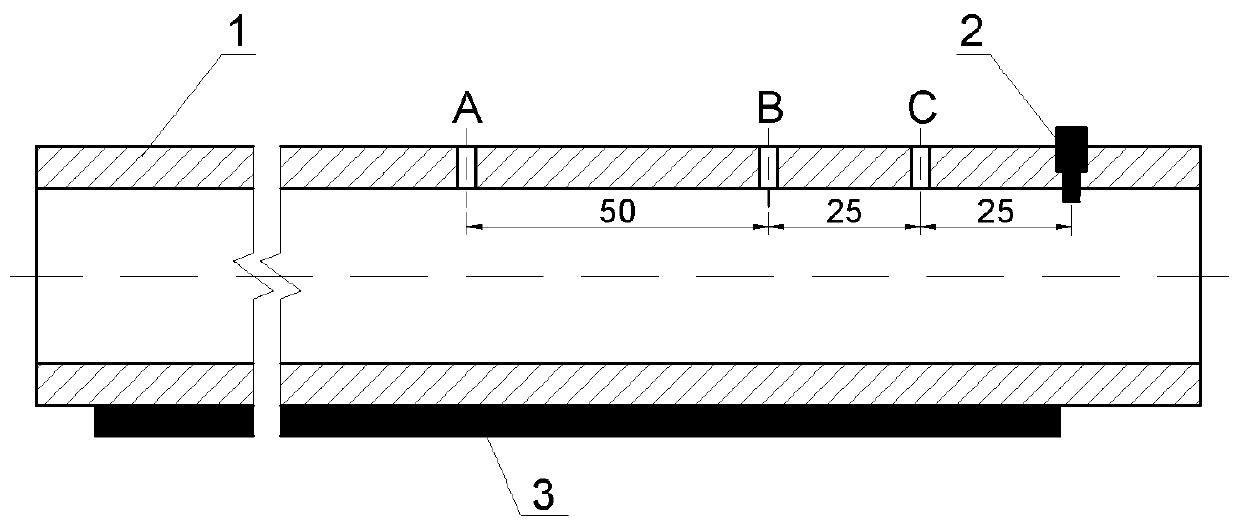

[0059] (3) if image 3 As shown, a hole A is drilled on the pipeline at a distance of 100cm from the circumferential monitoring electrode (the axial distance between point A and the circumferential monitoring electrode) to simulate pipeline leakage. At the lowermost axial monitoring electrode 3, the leaked water and the water in the pipeline will connect the axial monitoring electrode 3 and the circumferential mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com