Electric melting pipe with non-metal pipeline leakage monitoring function and machining method thereof

A technology for electrofusion pipe fittings and pipeline leakage, which is applied in the directions of pipes/pipe joints/pipe fittings, piping systems, and piping connection arrangements, etc., which can solve the problems of high construction cost, unsuitable acoustic detection technology for non-metallic pipes, and large noise interference. , to achieve the effect of reducing the ease of manufacturing, testing methods, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

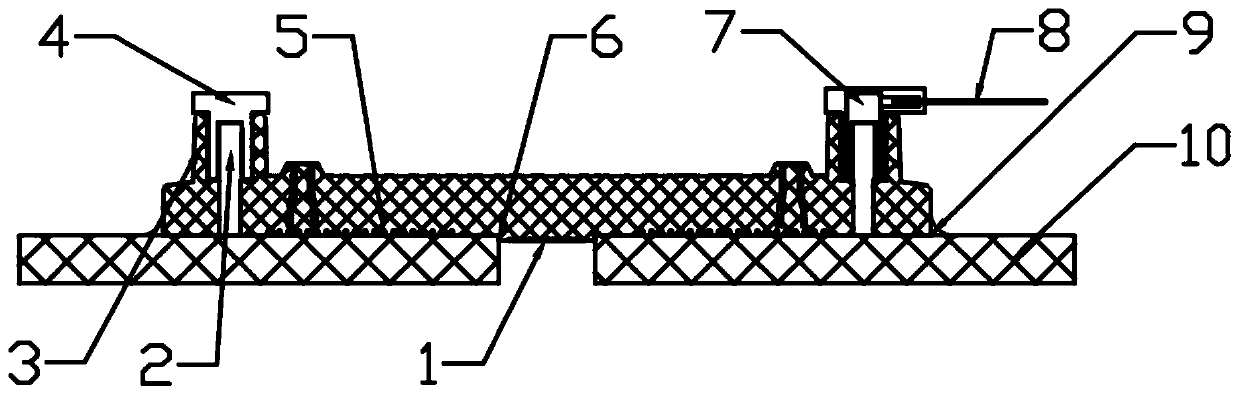

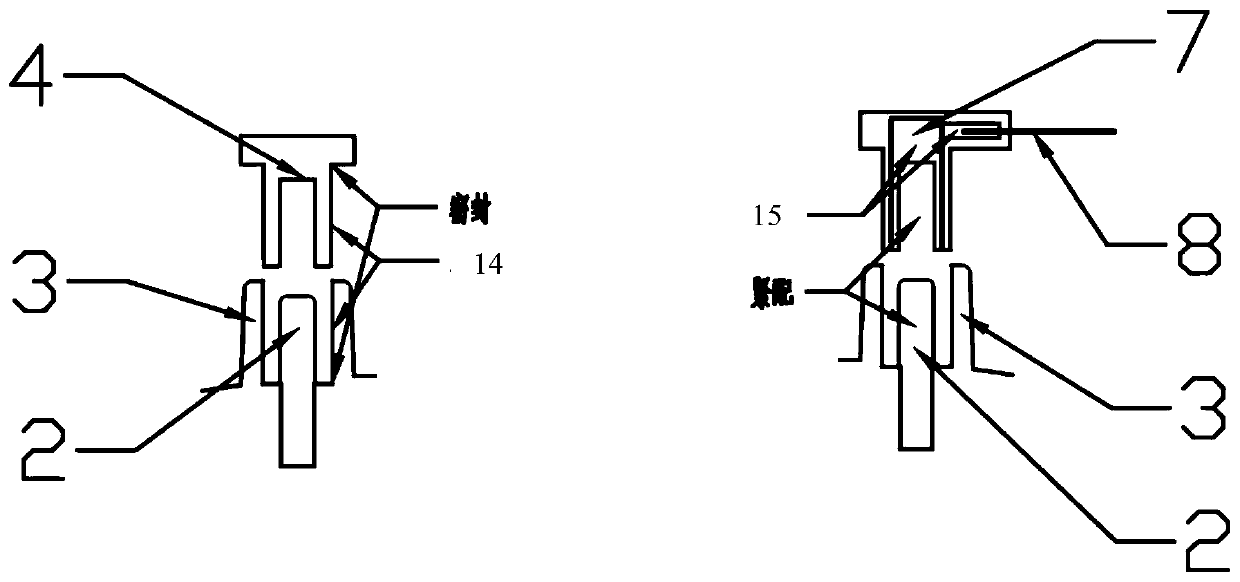

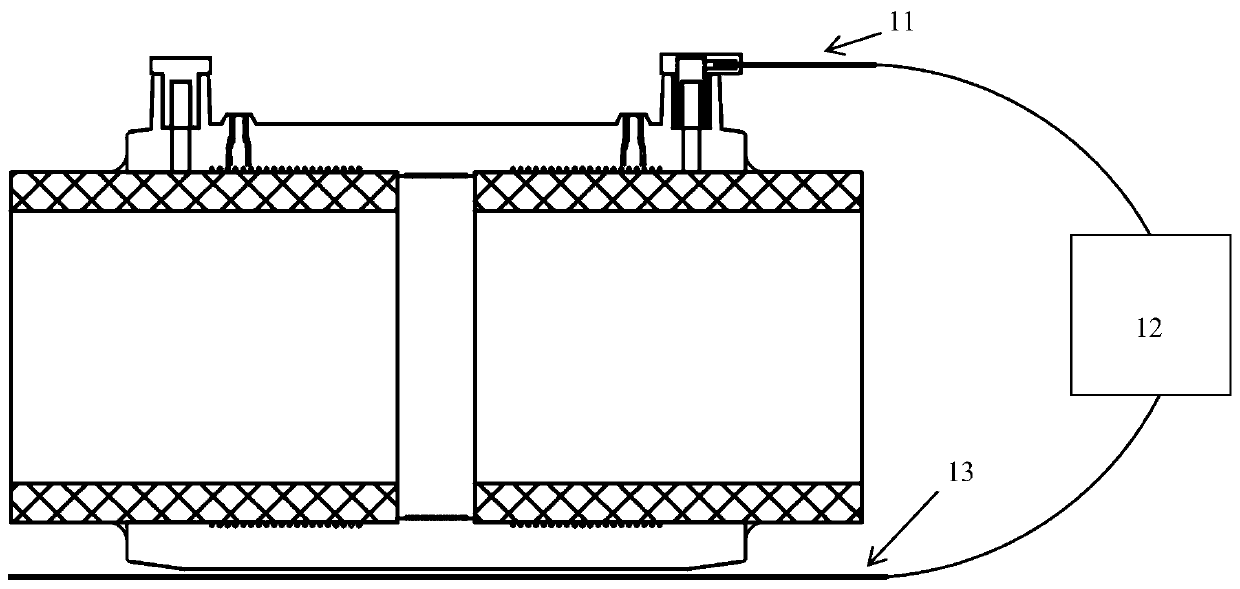

[0033] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034]In the present invention, the electric fusion pipe fitting with non-metallic pipeline leakage monitoring function includes a resistance wire 5 arranged inside the electric fusion pipe fitting for welding, and two terminal posts 2 made of metal are arranged on the outside of the electric fusion pipe fitting. The bottom end is respectively connected to both ends of the resistance wire 5; the terminal post 2 is set in a tubular sheath 3 made of insulating material, and the two sheaths 3 are respectively equipped with seals (complete seal 4 and seal 7 providing wiring seal);

[0035] The resistance wire 5 circles along the circumference of the electrofusion pipe to form two connected heating areas; the middle part used to communicate with the two heating areas is exposed in the inner cavity of the electrofusion pipe as the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com