A kind of microfluidic chip reagent ultrasonic mixing method

A microfluidic chip and ultrasonic technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of undisclosed microfluidic chip pretreatment, etc., to reduce reagent residue or loss, The effect of improving the utilization rate and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

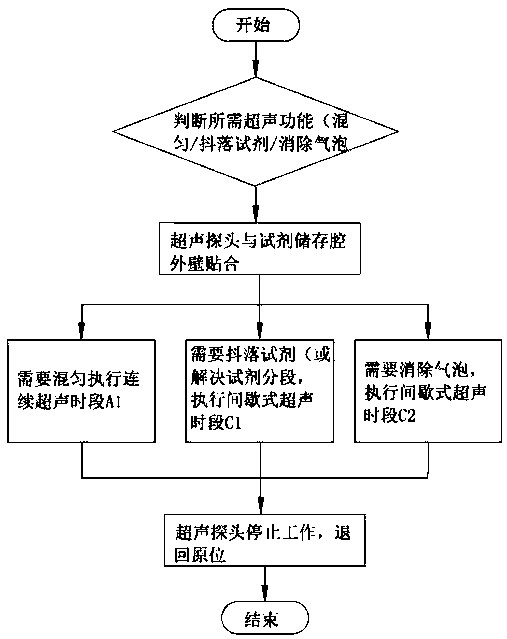

Method used

Image

Examples

Embodiment 1

[0056] Magnetic bead suspensions are used in chemiluminescent immunoassays or molecular diagnostic nucleic acid extraction processes. Although the types and particle sizes of magnetic beads are different, they are all composed of solid magnetic bead particles and diluents. After being stored in the chip, Sedimentation occurs on standing (eg figure 2 shown). If the deposited magnetic bead suspension participates in related reactions, the stability and reliability of the test results will be seriously affected. Therefore, in order to ensure accurate and reliable test results, the magnetic bead suspension must be mixed before use to resuspend and disperse the magnetic beads evenly. Therefore, it is necessary to perform continuous ultrasonic period A' to fully mix the magnetic beads; in addition, the magnetic bead liquid may splash on the plunger during the execution of A', causing the plunger to stick to a small section of reagent, which needs to be shaken back to the bottom aga...

Embodiment 2

[0077] Microfluidic chips will inevitably be bumped or even turned upside down during transportation, and a small amount of air bubbles may be mixed in the reagents. Due to the small diameter of the reagent storage chamber, a small piece of reagent may be attached to the plunger, and the liquid column may be stratified up and down (such as Figure 4 As shown), the reagent cannot fall back to the bottom of the reagent storage chamber smoothly only by its own gravity. The existence of air bubbles in the reagent or the problem of reagent segmentation may cause inaccurate volumes of reagents added to the reaction area, or it is necessary to add more reagents to the reagent storage chamber to reduce air, resulting in waste of reagents, reduced reagent utilization, and significantly increased testing costs. Because the reagent itself is a homogeneous solution in this example, it is not necessary to perform the continuous ultrasonic period A' for vigorous mixing, and only need to per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com