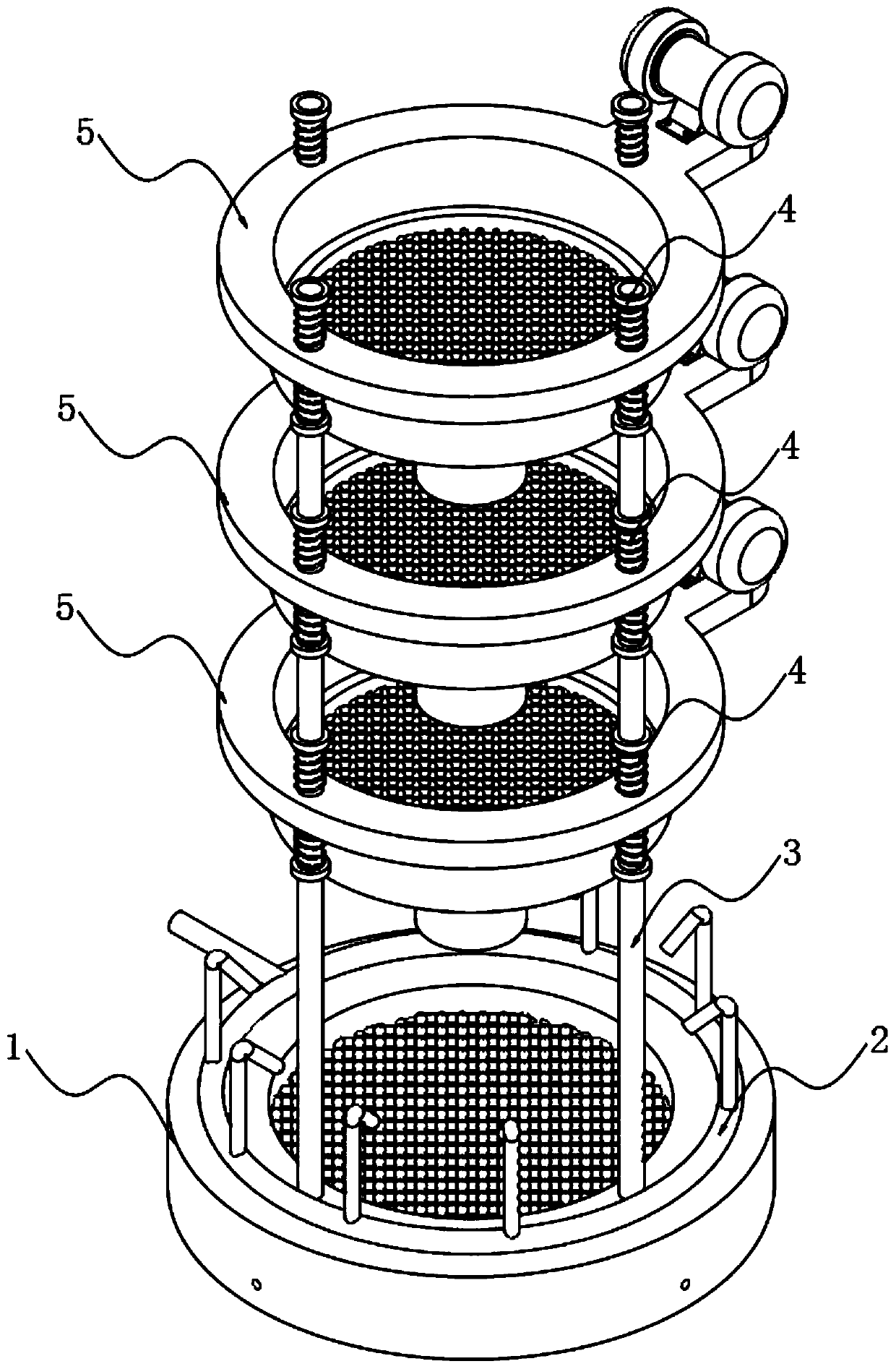

Multifunctional ore dressing machine

A kind of concentrator, multi-functional technology, applied in the direction of using liquid cleaning method, solid separation, filtering and screening, etc., can solve the problem of low efficiency of screening function, achieve the effect of solving low efficiency of screening function, easy to clean, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

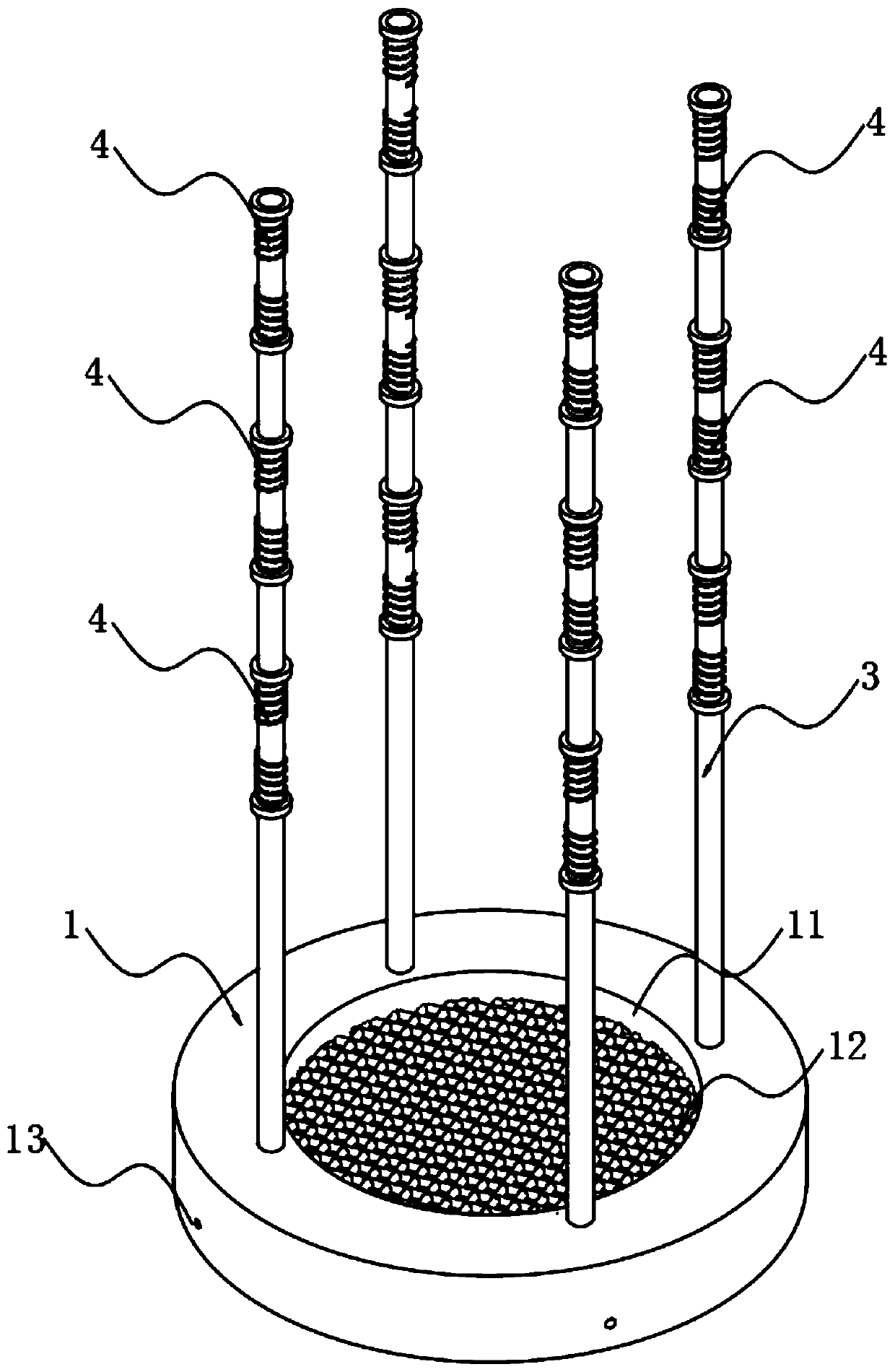

[0024] A multifunctional concentrator, such as figure 2 Shown, including base 1. Specifically, a cleaning cavity 11 is opened on the top surface of the base 1 , and a filter screen 12 is embedded on the inner wall of the cleaning cavity 11 .

[0025] In this embodiment, a plurality of drainage holes 13 are arranged in a circular and equidistant manner on the peripheral outer wall of the base 1 , and the drainage holes 13 communicate with the cleaning chamber 11 , and the drainage holes 13 are used to discharge waste water.

[0026] Further, the level of the drain hole 13 is lower than that of the filter screen 12 , and soil and waste water flow into the bottom of the cleaning chamber 11 through the filter screen 12 , so as to be discharged through the drain hole 13 .

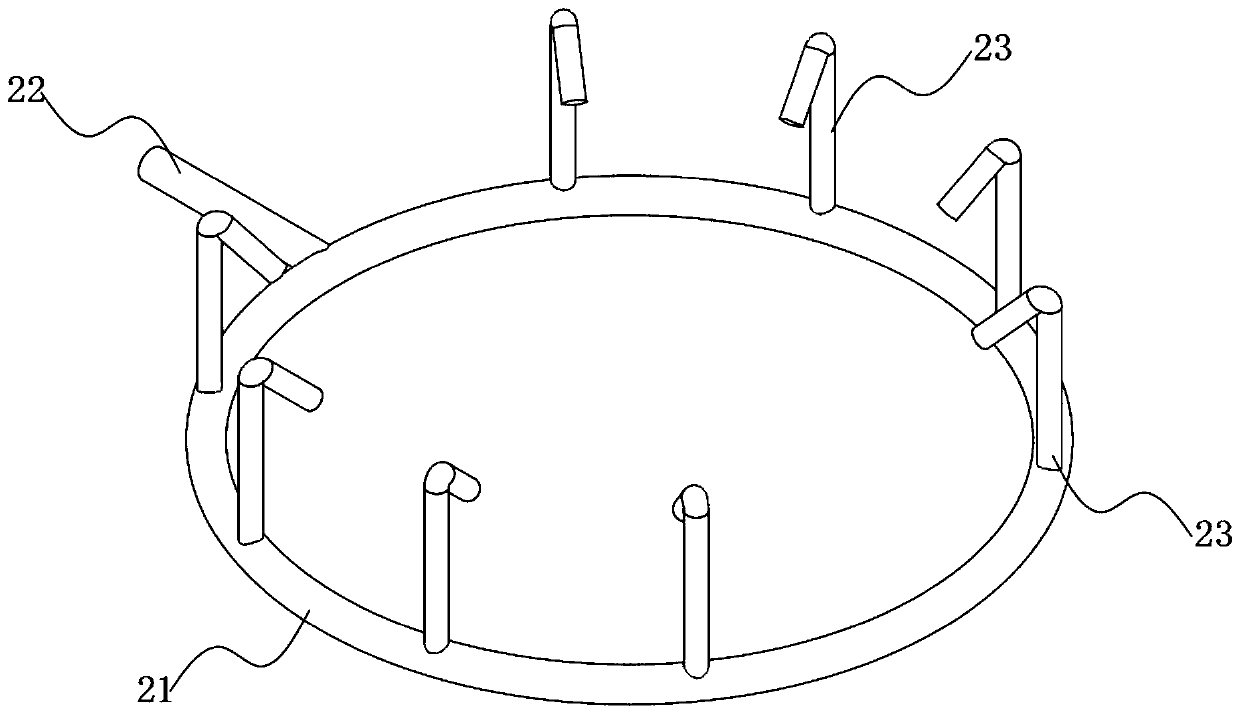

[0027] See image 3 , The top surface of the base 1 is provided with an ore washing mechanism 2. Specifically, the ore washing mechanism 2 includes an annular pipe 21 fixedly connected to the top surface of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap