Method of dealing with goaf by ultra-deep hole blasting in open-pit mine

A goaf and ultra-deep hole technology, which is used in blasting, earth-moving drilling, and discharging machinery, etc., can solve the problems of narrowing the mining area, limiting the production capacity of open-pit mines, and increasing the difficulty of detecting and processing gobs. The effect of improving mine production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

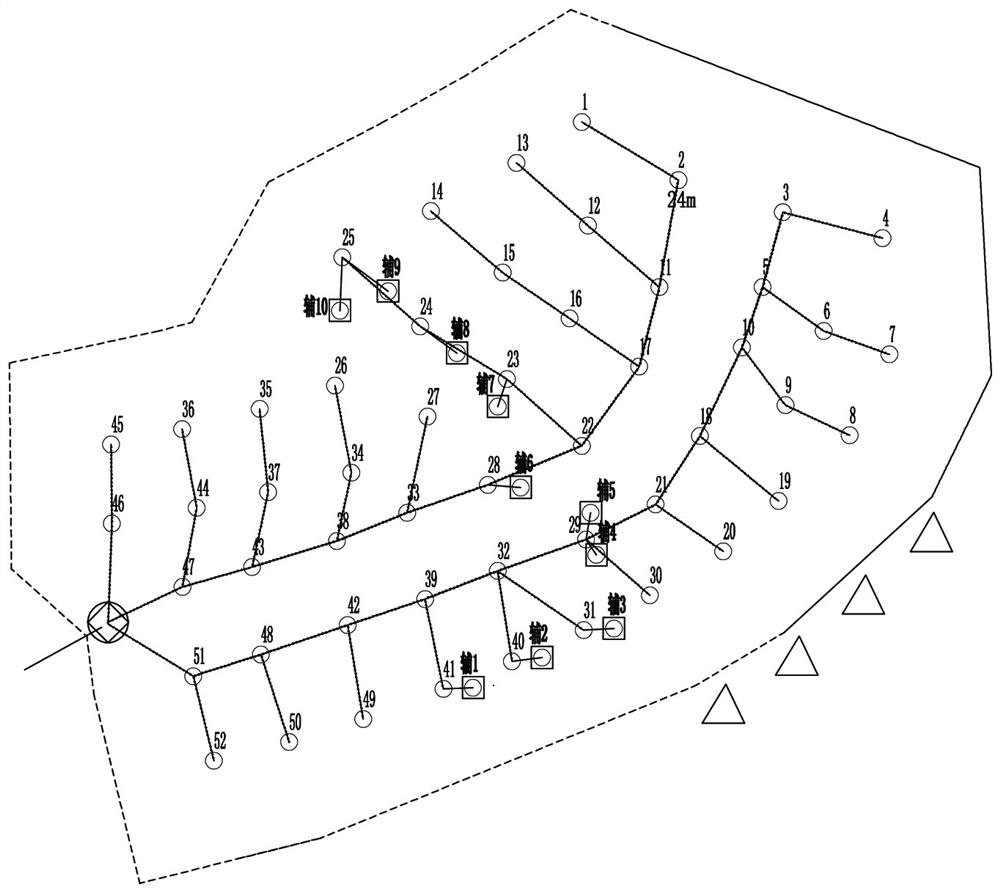

[0041] In the Dalazi mining area of Gongchangling Open-pit Iron Mine of Anshan Iron and Steel Co., Ltd., as the mining depth decreased, when mining the 288m level south side, the three-dimensional detection of the inside of the goaf was carried out through geological drilling combined with a three-dimensional laser detection system. There are two super-large goafs in this area, about 110m long from east to west, and about 50m long from north to south. ore pillars, resulting in the suspension of ore production in the Dalazi mining area. Such complex goafs are rare in domestic open-pit mines, and our mine has no practical experience in dealing with similar goafs.

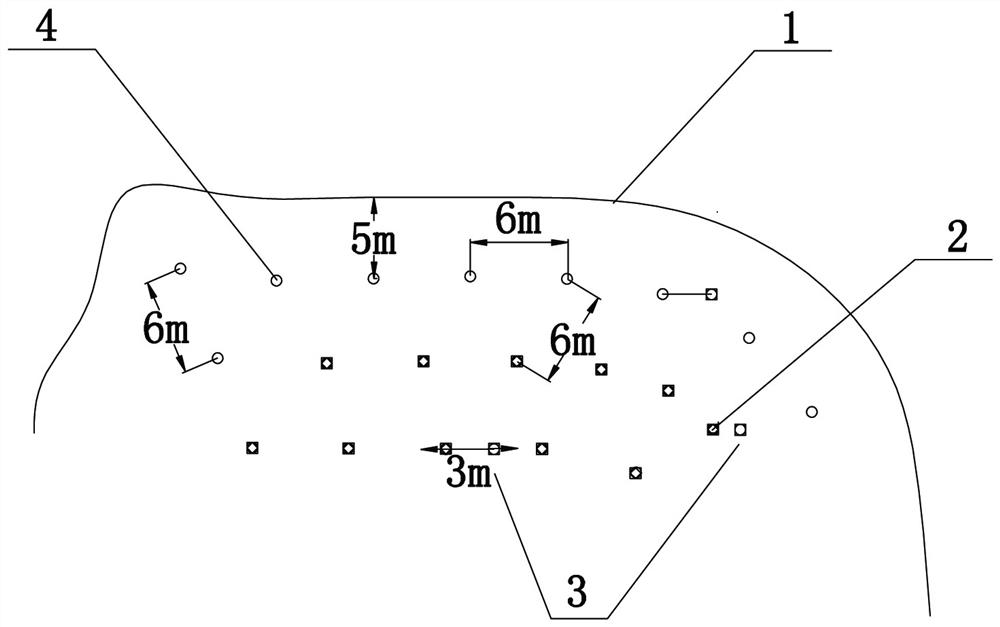

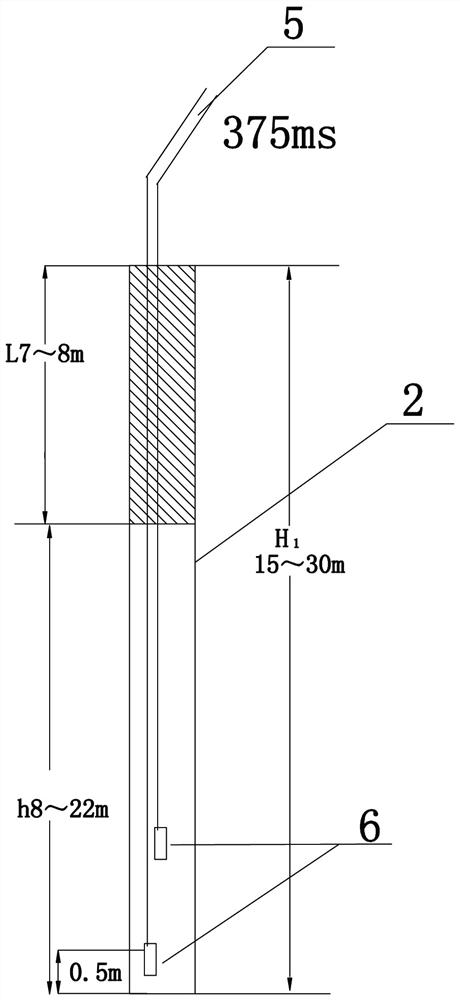

[0042] Such as Figure 7 As shown, the entire void area is divided into three explosion areas for treatment. The shaded areas I, II, and III in the figure are each an explosion area, and the thickness of the roof is small, the height of the void area is large, the slope is steep, and the filling effect is selected....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com