Method suitable for industrial image detection

An image detection and industrial technology, applied in the field of industrial image detection system, can solve the problems of complex collection of industrial product images and inability to obtain complete and clear images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

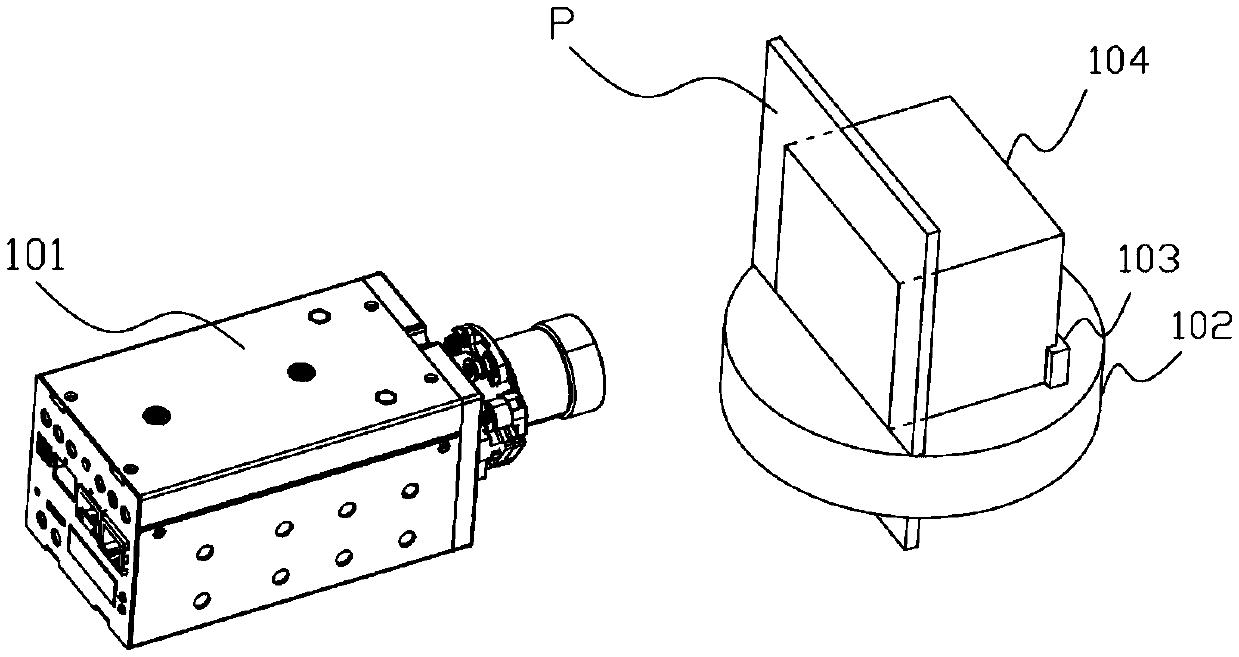

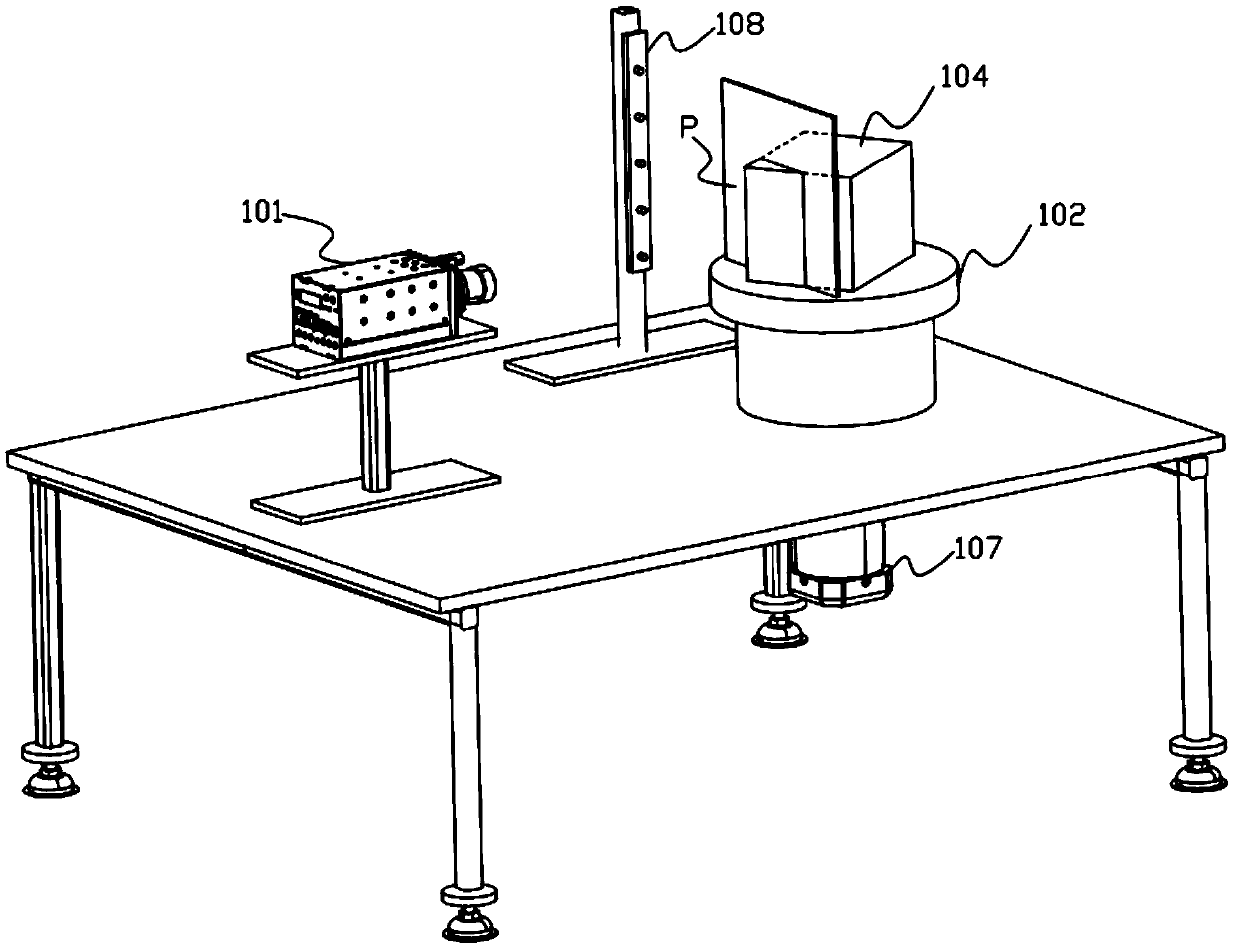

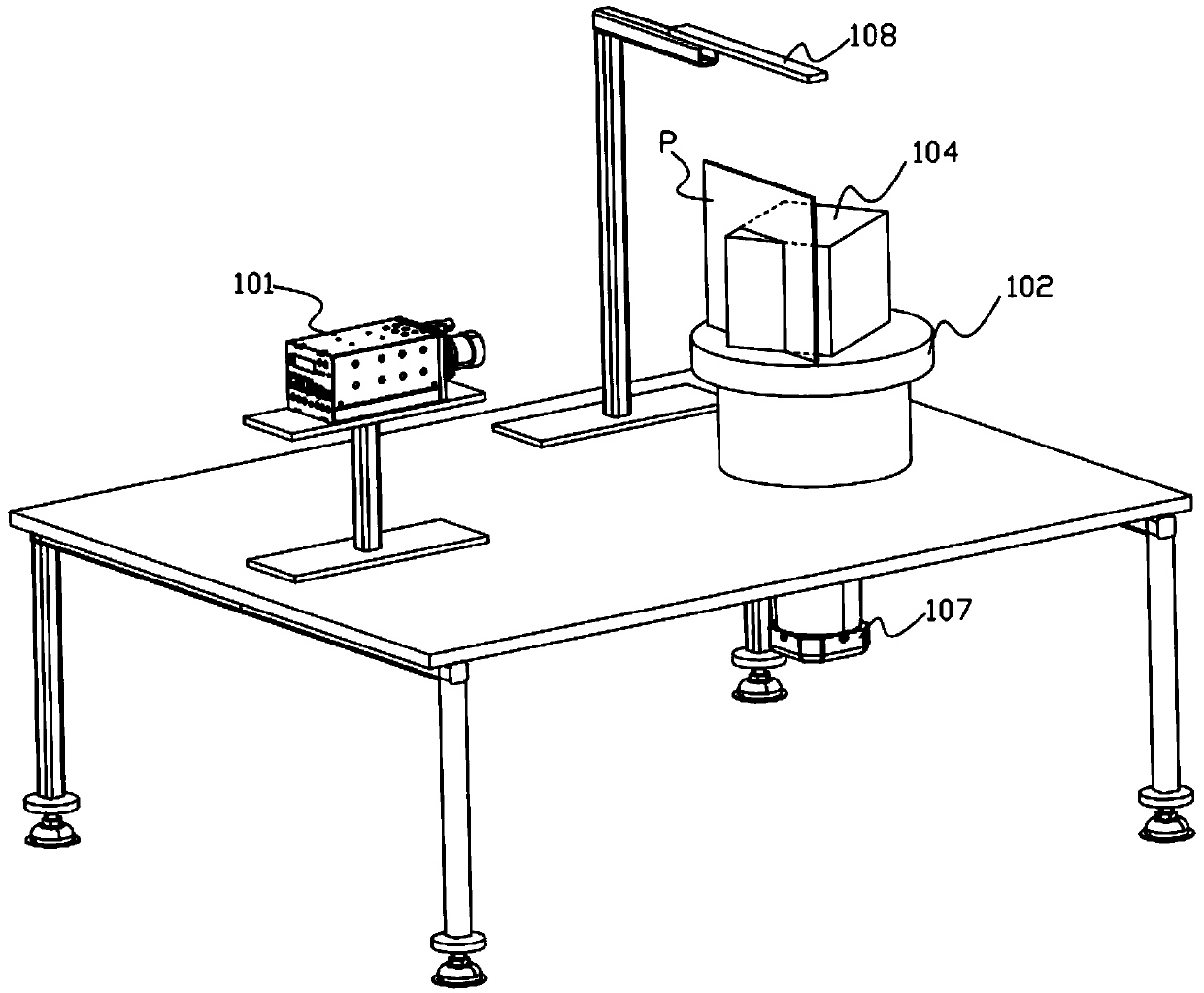

[0033] Clear imaging surface P

[0034] For an image acquisition device, such as a camera, video camera, scanner, etc., it can be known from optical principles that if the physical conditions such as the type and position of optical and electronic components in the image acquisition device are not changed, the distance and range that the camera can clearly image are often fixed. of.

[0035] Such as Figures 1A-1C As shown, the area that can be clearly photographed by the camera 101 is defined as the clear imaging plane P. Generally speaking, the shape of the clear imaging surface P depends on the hardware of the camera 101, especially the shape of the image sensor, Figures 1A-1C The example in FIG. 2 is drawn as a rectangle for illustration only, in fact, the clear imaging surface P can be in any shape. The size of the clear imaging plane P and its distance and angle from the camera 101 are determined by the relative relationship between the lens and the image sensor.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com