New energy vehicle shock-absorbing battery box

A technology for new energy vehicles and battery boxes, which is applied to battery pack parts, circuits, electrical components, etc. It can solve the problems of shortened battery life, loose battery wiring, and inconvenient use, so as to prolong the service life and effectively install , to ensure normal and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be further described below in conjunction with the accompanying drawings, but it is not used to limit the scope of the present invention.

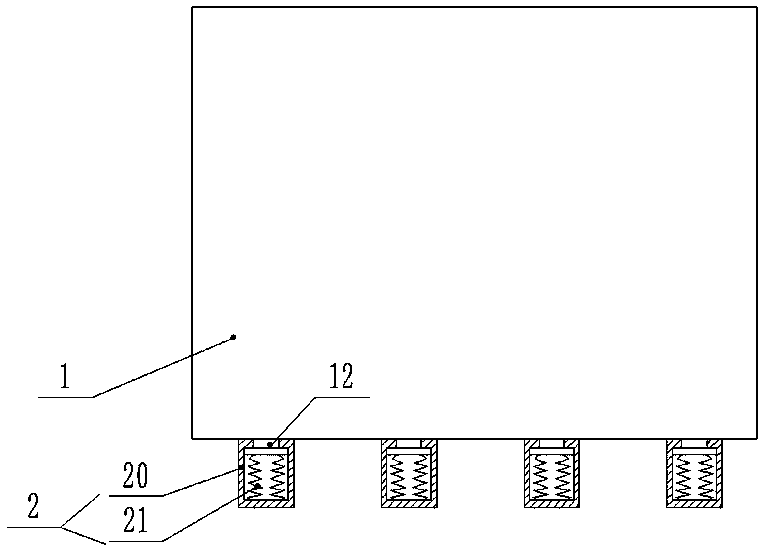

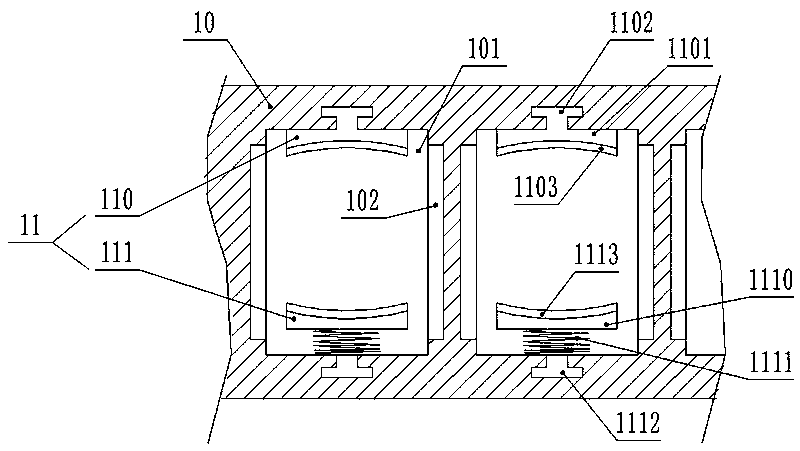

[0021] Such as figure 1 with 2 As shown, a shock-absorbing battery box for a new energy vehicle provided by the present invention includes a battery box body 1 and a shock-absorbing mechanism 2 installed at the bottom of the battery box body 1, and the shock-absorbing mechanism 2 includes a hollow rubber column 20 and A spring 21 located in the hollow rubber column 20, a connector 12 is provided under the battery box body 1, and the connector 12 extends into the hollow rubber column 20 to connect with the spring 21; The quantity of shock mechanism 2 is multiple.

[0022] The present invention realizes the shock absorbing function of the battery box body 1 through the shock absorbing mechanism 2, reduces the shock that the battery is subjected to during the running of the car, and weakens the impact of the shock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com