IGBT parallel driving adaptive circuit and circuit board

An adaptation circuit and parallel connection technology, applied in the direction of electrical components, output power conversion devices, etc., can solve problems such as large electrical stress, IGBT damage, device damage, etc., and achieve the effect of low cost and simple circuit structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

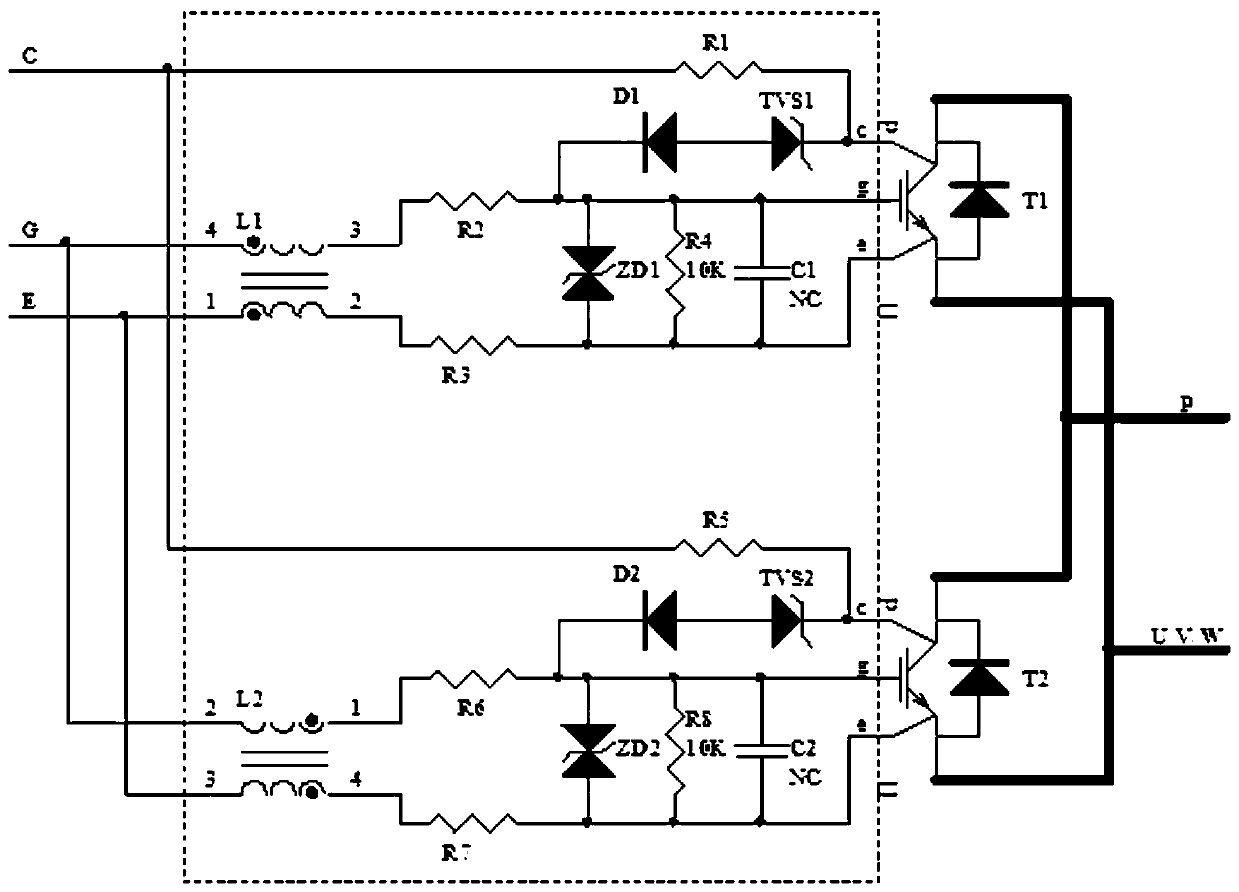

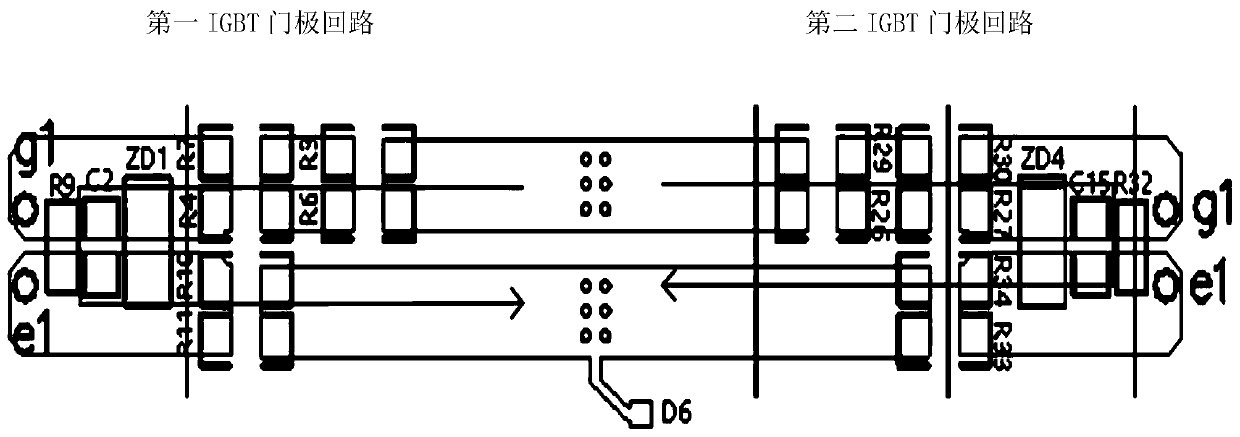

[0026] like figure 1 As shown, an IGBT parallel drive adaptation circuit includes an IGBT parallel unit; the IGBT parallel unit includes a first IGBT, a second IGBT, a resistor R1, a resistor R2, a resistor R3, a resistor R5, a resistor R6, and a resistor R7; The IGBT is connected in parallel with the second IGBT.

[0027] One end of the resistor R1 is electrically connected to the collector of the first IGBT, one end of the resistor R5 is electrically connected to the collector of the second IGBT, the other end of the resistor R1 is electrically connected to the other end of the resistor R5, and the connection between the resistor R1 and the resistor R5 forms an IGBT in parallel C pole of the unit.

[0028] One end of the resistor R2 is elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com