Brush bristle planting machine capable of realizing co-hole multi-color bristle planting, and bristle planting method

A hair-planting machine and hair-planting technology, applied in the brush hair-planting machine, brush hair-planting machine and their hair-planting fields, to achieve the effects of simple structure, high production efficiency, and improved manufacturing process level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the description of the drawings and the specific embodiments.

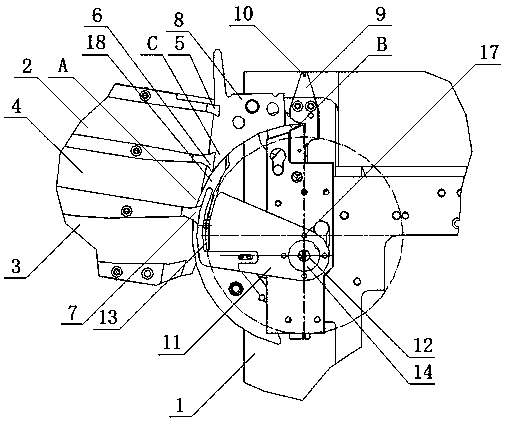

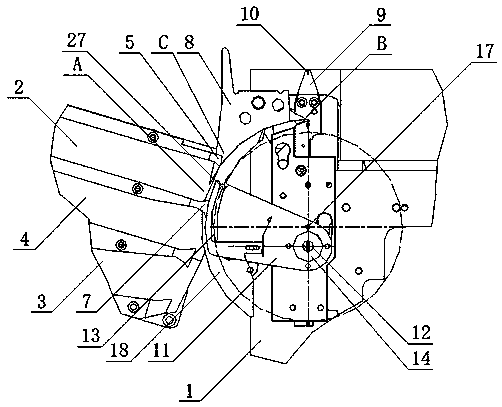

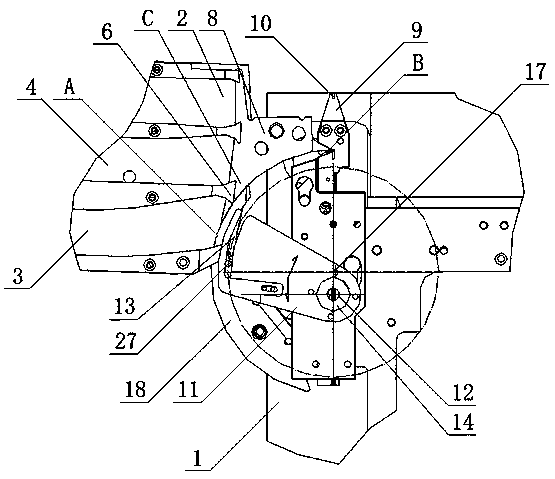

[0041] See Figure 1 to Figure 10 , The present invention is a bristle planting machine capable of planting multi-color hairs in the same hole, comprising a frame 1, two or more brush boxes are arranged on the outside of the frame 1, and the side of the brush box is close to one of the frame 1. The side opening is provided with a brush box outlet, which is characterized in that: the frame 1 is equipped with a hair removal device 18 through the hair removal device seat, and the outer side of the hair removal device 18 is provided with an inner arc surface corresponding to the hair stopper on the frame 1. The outer arc surface 19, the outlet of the brush box are respectively located outside the outer arc surface 19, the outer arc surface 19 is provided with a large hair removal gap 21, and the hair removal device 18 is located in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com