Novel electromagnetic centrifugal casting process and equipment for furnace tube

A furnace tube process and centrifugal casting technology, applied in the field of centrifugal casting, can solve the problems of limited cooling capacity of chrome-molybdenum steel molds, the type of liquid metal crystallization mode cannot reach the best ideal state, and the performance and service life of furnace tubes are affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

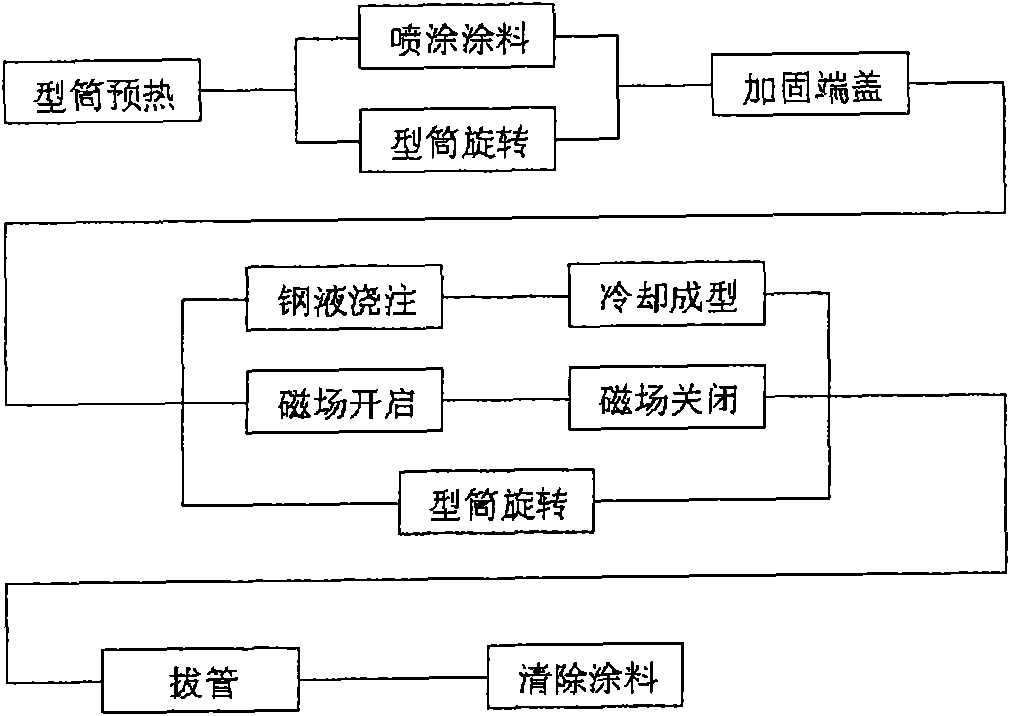

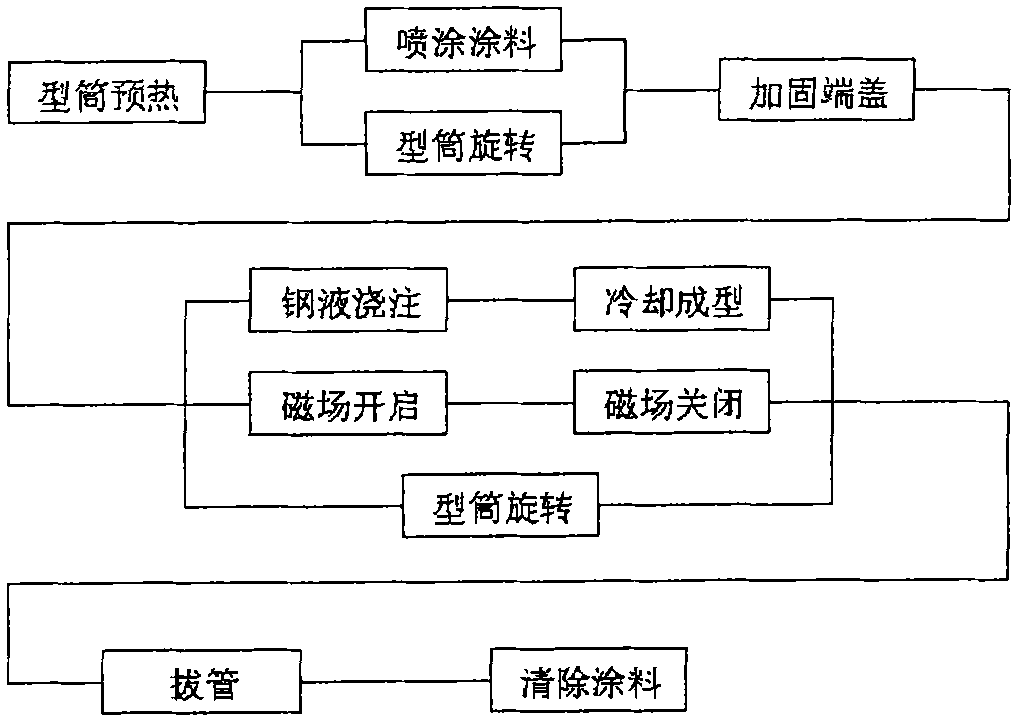

[0009] The following is an analysis of the production and operation of the new furnace tube electromagnetic centrifugal casting process and equipment:

[0010] 1 Fabrication of magnetic field generator

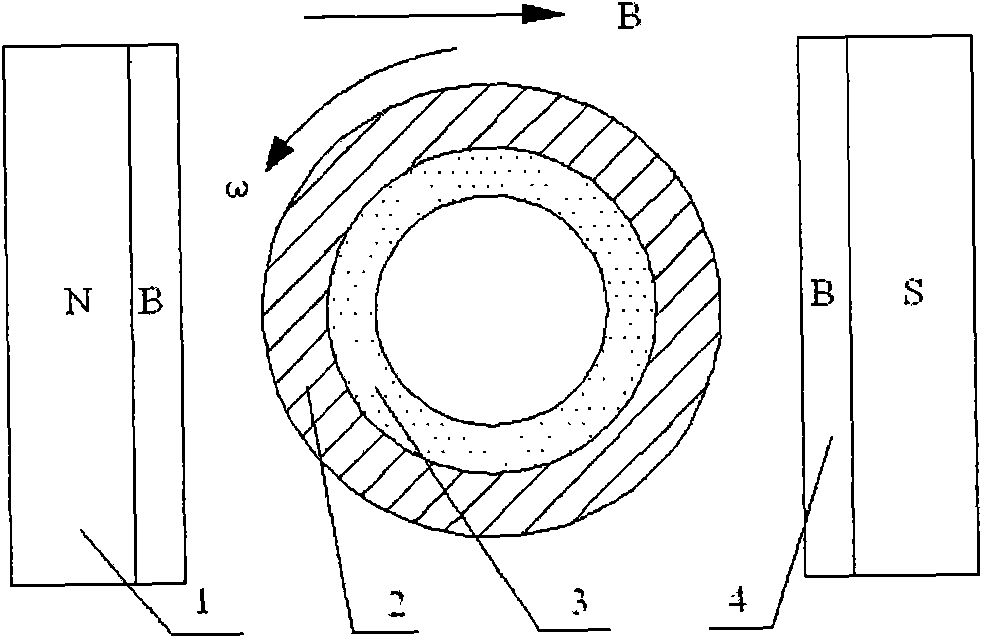

[0011] According to actual needs, a magnetic field with a size of 5m*0.3m*1m needs to be generated in a space with a width of 1 meter left and right centered on the molded cylinder 2 . The magnetic field generator uses excitation coils in parallel to make large-scale magnetic poles, forming a single magnetic pole 1 on both sides of the molded cylinder, and adding a heat-insulating cooling layer 4 between the magnetic poles and the molded cylinder, and the magnetic field strength is adjusted by the excitation voltage.

[0012] Because the wall thickness of the cylinder used in centrifugal casting is relatively large, and it is in a high temperature state during operation. Therefore, the production of the magnetic field generator fully considers the working conditions of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com