Intelligent pump station operation and maintenance method

A pumping station, operation and maintenance technology, applied in the field of intelligent pumping station operation and maintenance, can solve the problems of less choice of operation and maintenance personnel, large workload of operation and maintenance personnel and pumping station management center, fixed work content of operation and maintenance personnel, etc. The effect of improving autonomous selectivity, shortening troubleshooting time, and speeding up troubleshooting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

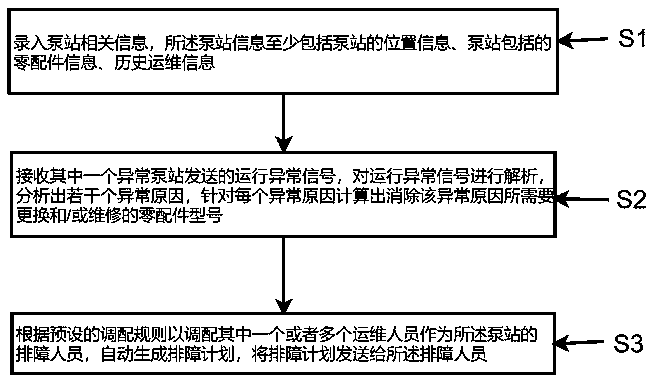

Method used

Image

Examples

Embodiment 1

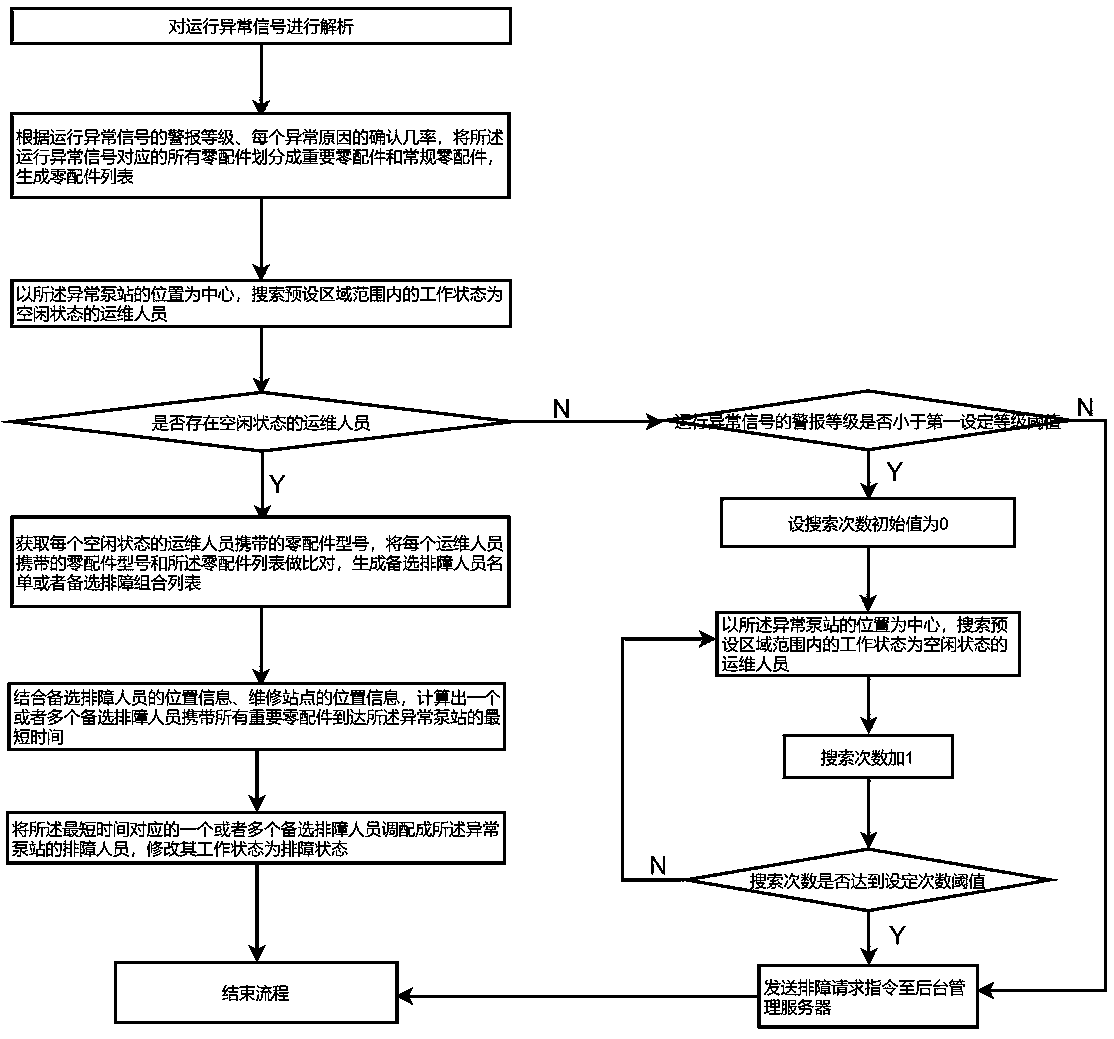

[0107] In step S34, the process of calculating the shortest time for one or more operation and maintenance personnel to carry all important spare parts to the abnormal pumping station includes the following steps:

[0108] S3401: Count the spare parts models carried by all idle operation and maintenance personnel within the preset area, and compare the statistical results with the spare parts list. Among them, if any operation and maintenance personnel carry the No. For the first important spare parts and the second most important spare parts, only the first important spare parts are counted. As in the previous example, when an operation and maintenance personnel carries spare parts A1, A2 and When , only spare parts A1 and A2 are counted, spare parts are not counted .

[0109] S3402: Calculate the combination of M troubleshooting personnel who carry the most important spare parts in total. The important spare parts for the same abnormal cause in the same combination of tr...

Embodiment 2

[0117]If the maximum number of troubleshooting personnel is 1, another method can be used to select the best troubleshooting personnel by comprehensively considering troubleshooting time and troubleshooting efficiency. specific:

[0118] In step S34, the process of calculating the shortest time for one or more operation and maintenance personnel to carry all important spare parts to the abnormal pumping station includes the following steps:

[0119] S3411: Count the spare parts models carried by all idle operation and maintenance personnel within the preset area, and compare the statistical results with the spare parts list. For the first important spare parts and the second most important spare parts, only the first important spare parts are counted.

[0120] S3412: According to the number of abnormal causes that can be solved by the important spare parts carried, the confirmation probability of the corresponding abnormal cause, and whether it belongs to a temporary troubles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com