Wiring connector

A technology of connectors and wiring chambers, applied in the direction of vehicle connectors, connections, clamping/spring connections, etc., can solve the problems of inconvenient installation and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

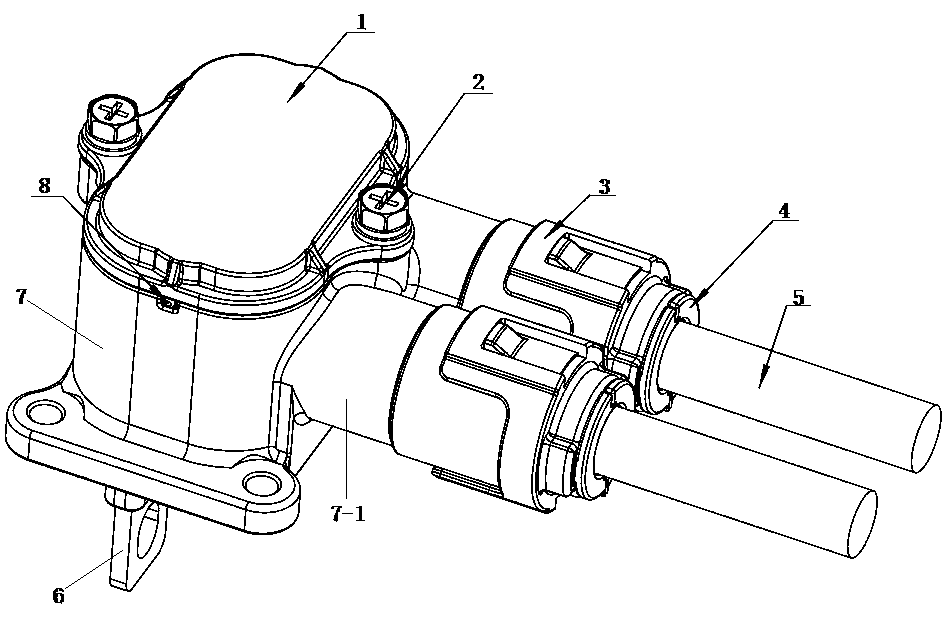

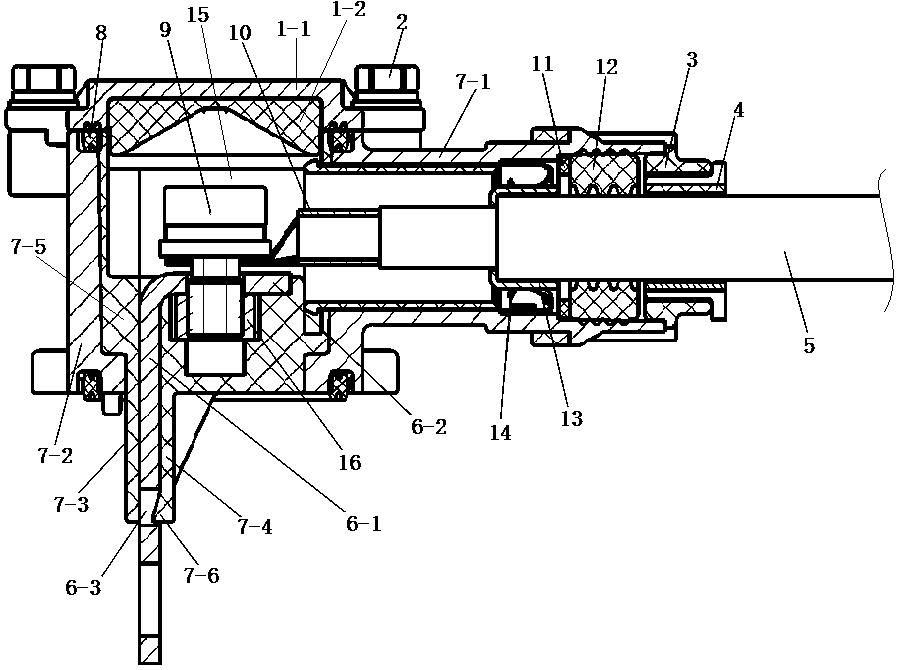

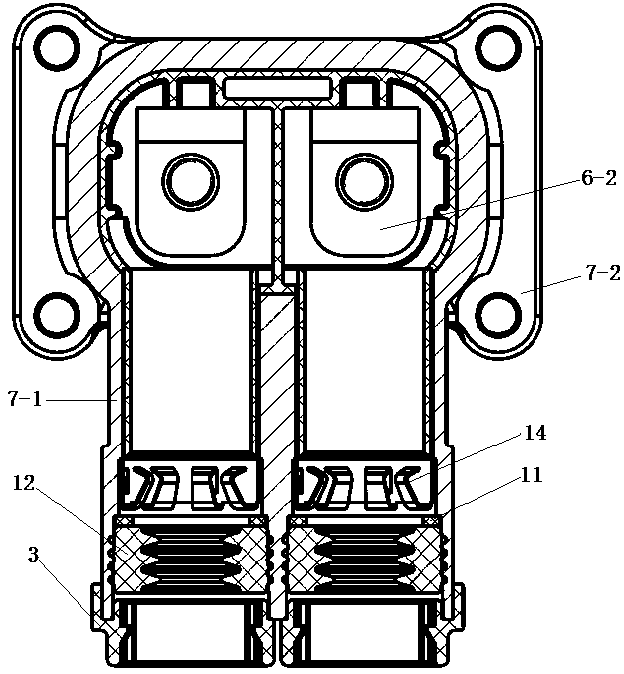

[0020] An example of the wiring connector in the present invention is Figure 1~Figure 8 As shown, it includes a base 7 and an upper cover 1 that is buckled and connected with the base 7. The base 7 and the upper cover 1 together form a wiring cavity 15. The upper cover 1 includes an upper cover housing 1-1 and an upper cover housing 1. The upper cover insulator 1-2 in -1, the base 7 includes a base shell 7-2 and a base insulator 7-5 arranged in the base shell 7-2, wherein the base shell 7-2 includes an integrally formed front and rear The base cylinder 7-1 extending in the direction, the base cylinder 7-1 communicates with the wiring cavity 15, the inner hole of the base cylinder 7-1 forms a threading hole for the cable 5 to pass through, so that the cable 5 end The connection terminal 10 protrudes into the connection cavity 15 from the back to the front.

[0021] The base insulator 7-5 is provided with a wiring nut installation hole, and a wiring nut 16 is arranged in the w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap