Snap button

A technology of snaps and female buttons, applied in the direction of fasteners, press fasteners, press fasteners, etc., can solve the problems of making noise, increasing the weight and size of the button, and not wanting to use it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

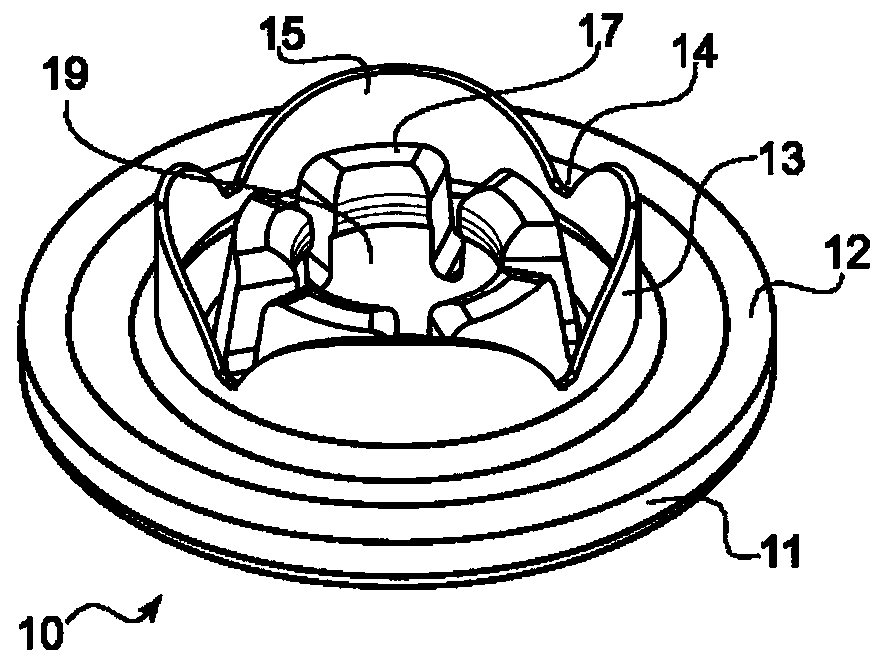

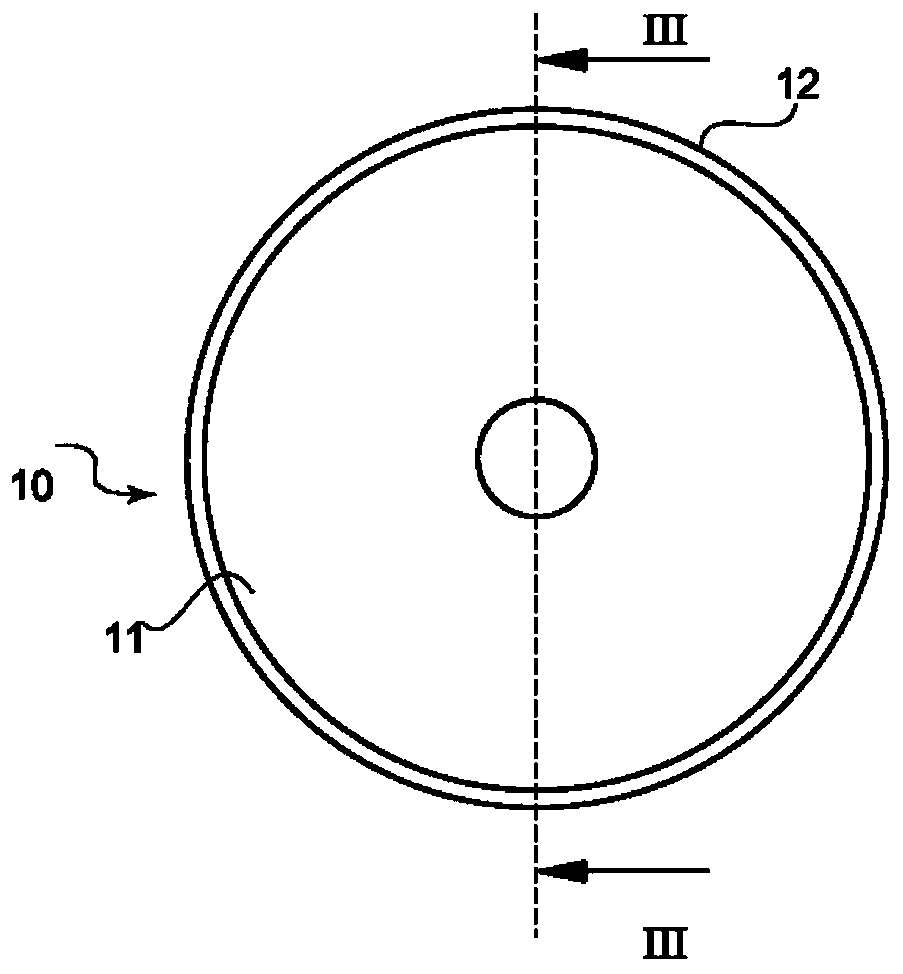

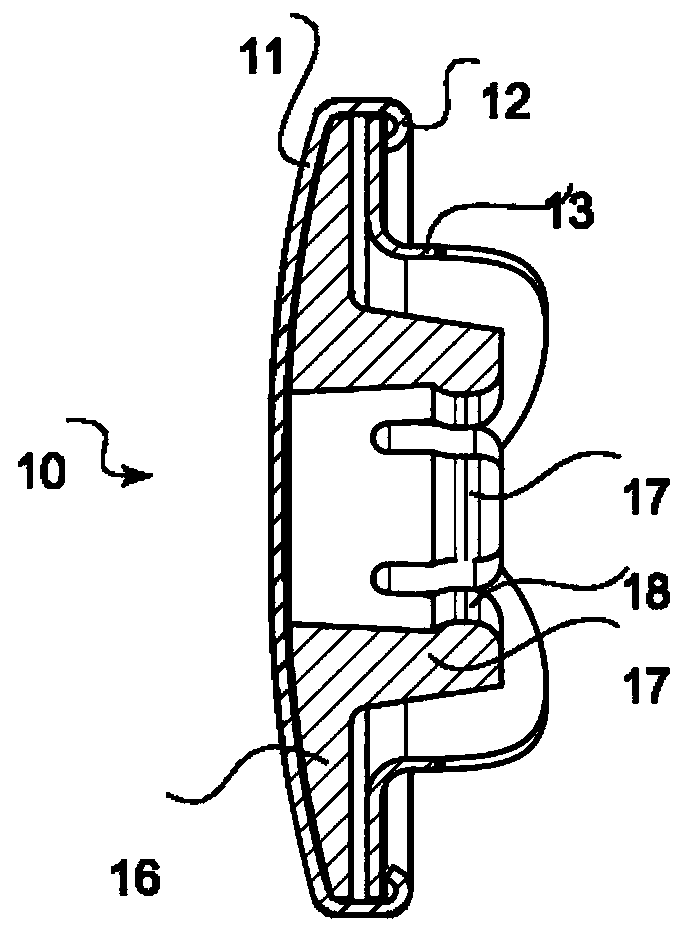

[0032] Referring now to the drawings in detail, and in particular, Figure 1 to Figure 3 A snap-on cap 10 according to the invention is shown. The cap 10 has a base body 11 with a rim 12 and an annular flange 13 extending upwardly from the base body 11 . The annular flange 13 has a plurality of discontinuities 14 around its circumference to form a plurality of evenly distributed prongs 15 . Arranged inside the base body 11 and below the flange 13 is an insert 16 which has a plurality of teeth 17 arranged in a circumferential manner on the inside of the flange 13 . The insert 16 is preferably made of plastic and the teeth 17 are preferably arranged with spaces between them.

[0033] Figure 4 to Figure 6 A socket 20 according to the invention is shown. The socket 20 is annular in shape with a central aperture 21 , a top rim 22 and a bottom rim 23 . The circumference of the top rim 22 is smaller than the circumference of the bottom rim 23 . An annular insert 24 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com