Plastic molded product

A molded product and plastic technology, applied in the field of plastic molded products, can solve the problems of conical top impact breaking, low mirror gloss, poor durability, etc., and achieve the effect of not easy to break, reduce mirror gloss, and not easy to wear off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

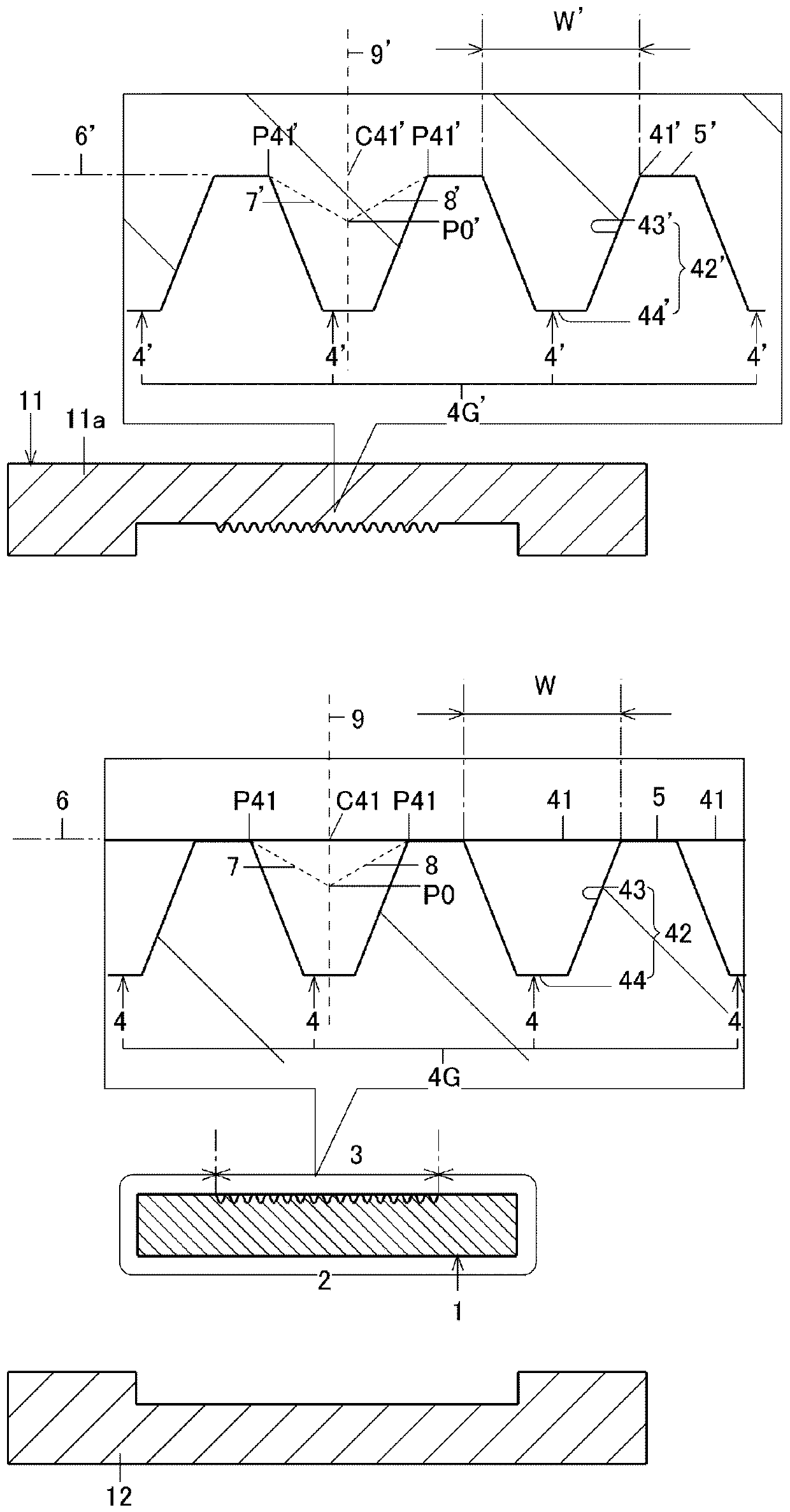

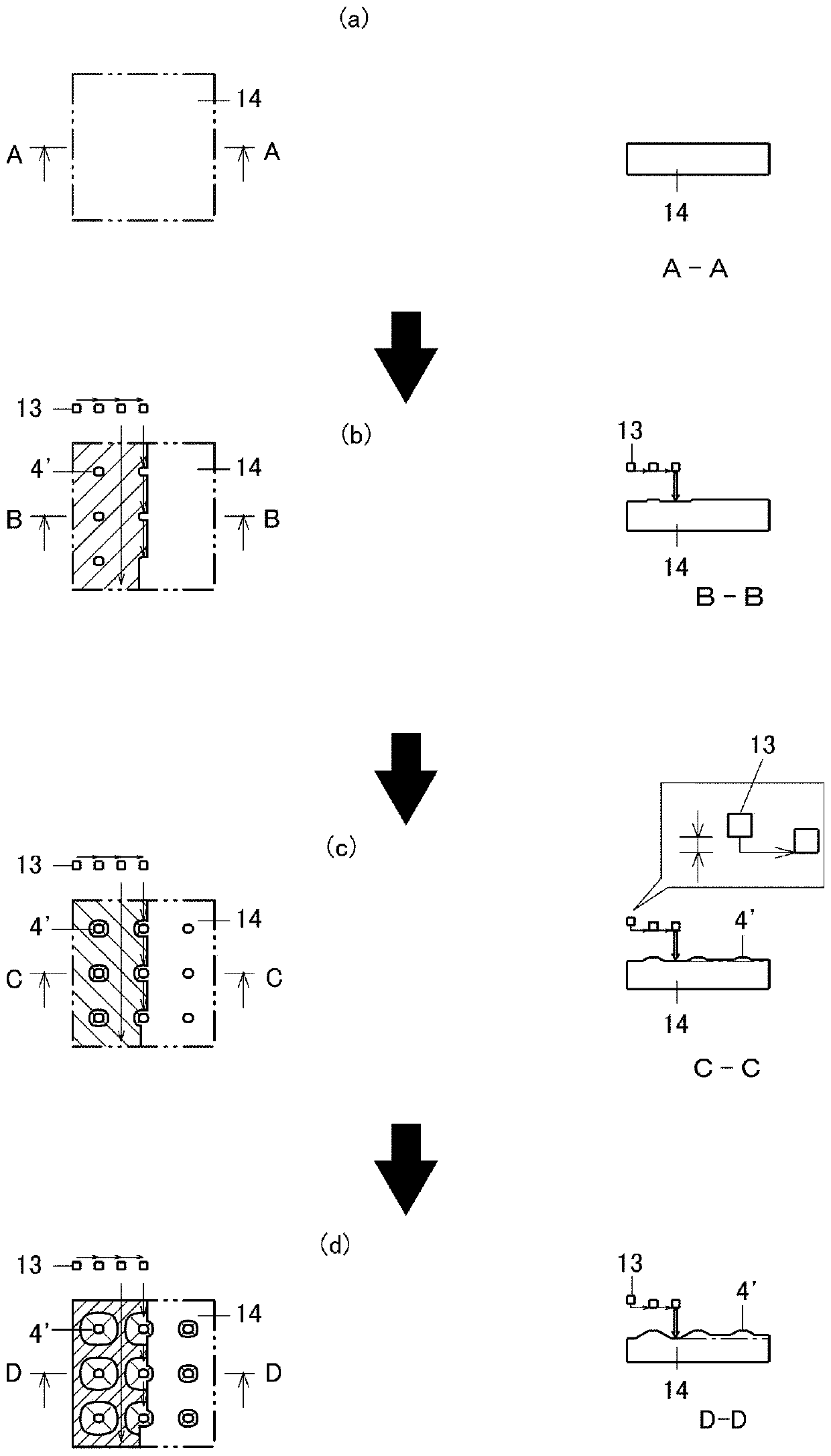

[0061] Such as figure 1 As shown, the plastic molded article of the first embodiment of the present invention is composed of a plastic main body 1 . The plastic main body 1 is made of, for example, POM (polyoxymethylene), and has a region 2 with relatively high specular gloss and a region 3 with relatively low specular gloss on its surface.

[0062] The region 2 with a high specular gloss is a portion with a specular gloss of 5.5 or more, and in this embodiment, is the surface of the non-porous plastic main body 1 .

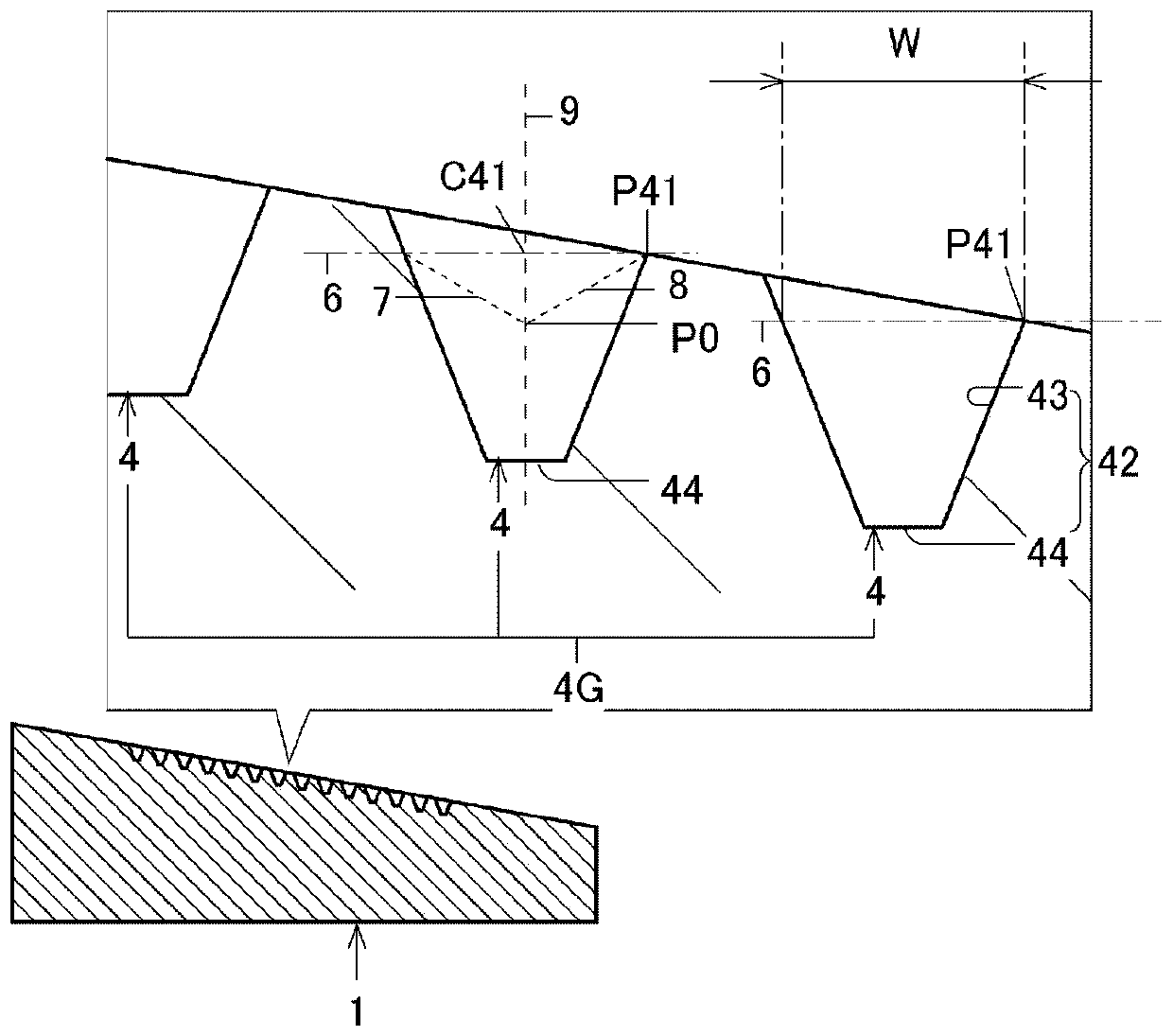

[0063] The region 3 with a small specular glossiness is a portion with a specular glossiness of less than 5.5. In this embodiment, a hole group 4G consisting of a plurality of holes 4 recessed from the surface of the plastic body 1 and a hole group 4G formed in the plastic body 1 are provided. The surface is the surface body surface 5 between adjacent holes 4 , 4 .

[0064] The main body surface 5 is a surface on which a plurality of holes 4 are opened, in oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com