Box sticking and forming equipment for packaging carton manufacturing

A molding equipment and box gluing technology, used in packaging, transportation and packaging, box making operations, etc., can solve the problems of small-scale production factory supporting facilities, high tension at both ends of the carton, and loose colloid adhesion, etc., to reduce Equipment cost, firm colloid, and the effect of not easy to open the glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

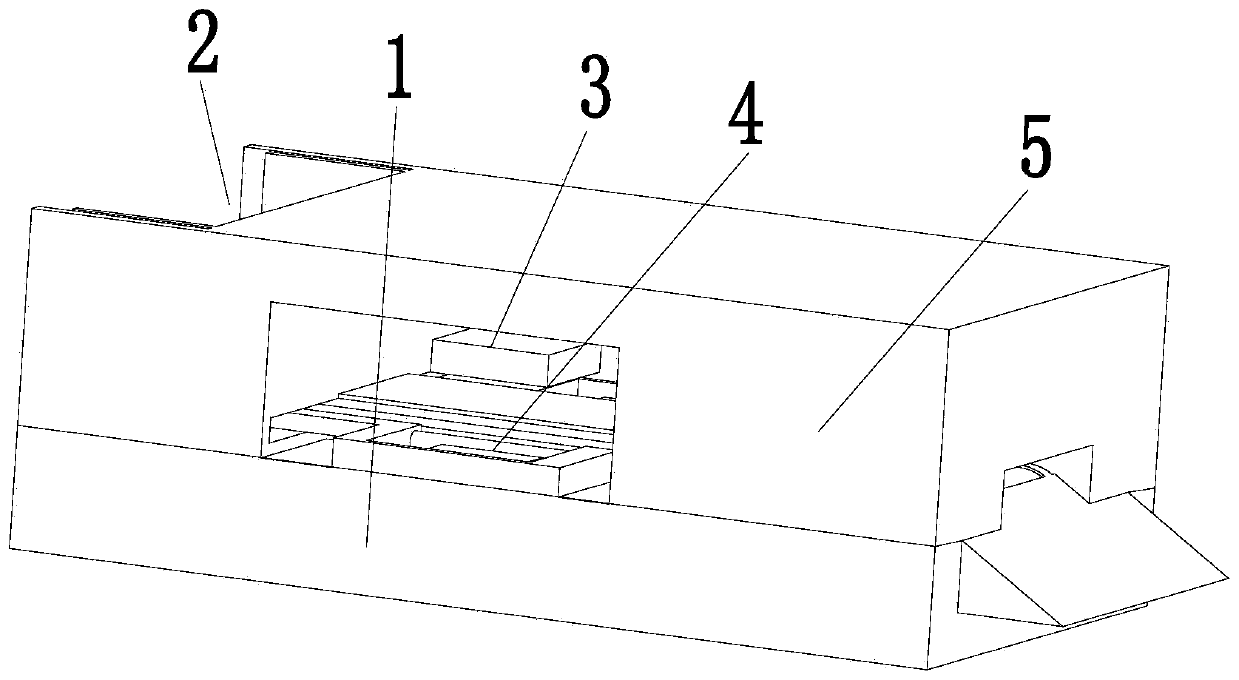

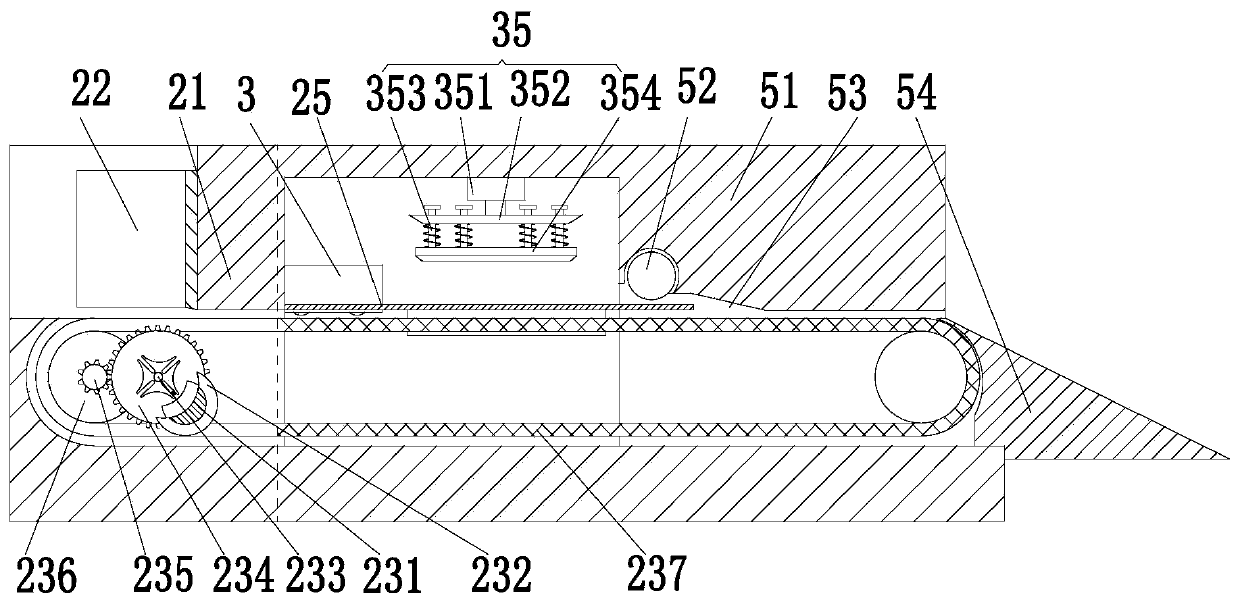

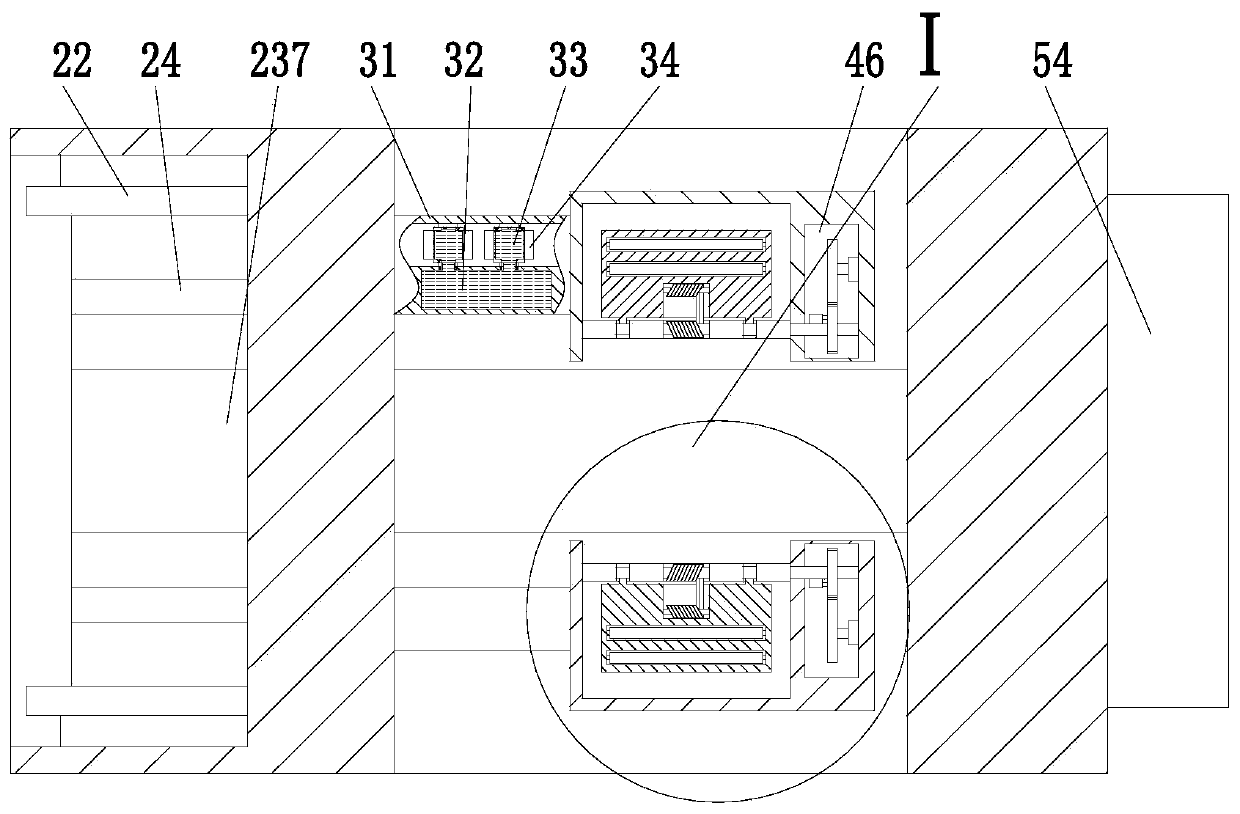

[0028] Such as Figure 1 to Figure 6 As shown, a glue box forming equipment for making packaging cartons, including a base 1, a feeding device 2, a gluing device 3, a turning device 4 and a feeding device 5, the upper end of the base 1 is provided with a belt groove, and the base 1 From left to right, there are feeding device 2, turning device 4 and unloading device 5, and the right end of feeding device 2 is equipped with gluing device 3; The gluing surface is treated with gluing, and the folding device 4 folds up the cardboard folding surface and sticks it well, and the stuck cardboard is exported from the blanking device 5 for blanking.

[0029] The feeding device 2 includes a feeding wall 21, a material guide frame 22, a feeding mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com