A kind of waterproof ECC and carbon fiber cloth composite reinforcement material and its application method

A technology of reinforcing material and carbon fiber cloth, applied in bridge reinforcement, building maintenance, bridge maintenance and other directions, can solve the problems of high ECC cost, carbon fiber cloth failure, uneconomical, etc., to simplify construction procedures, prevent external water intrusion, and achieve durable performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

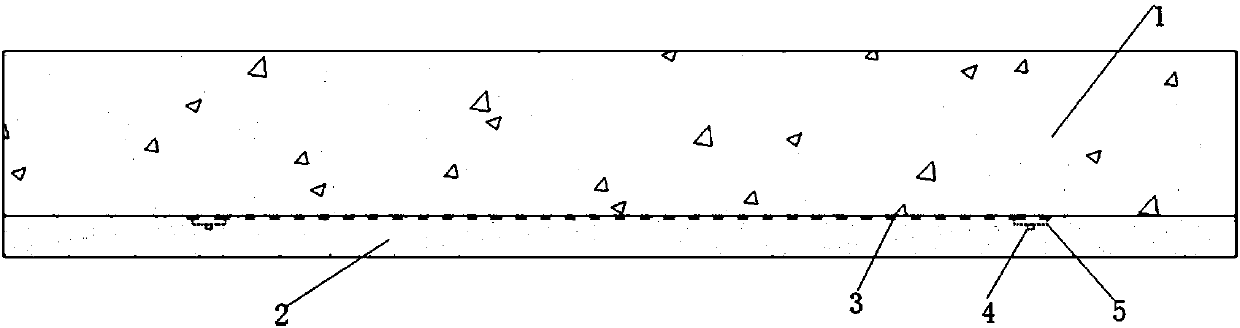

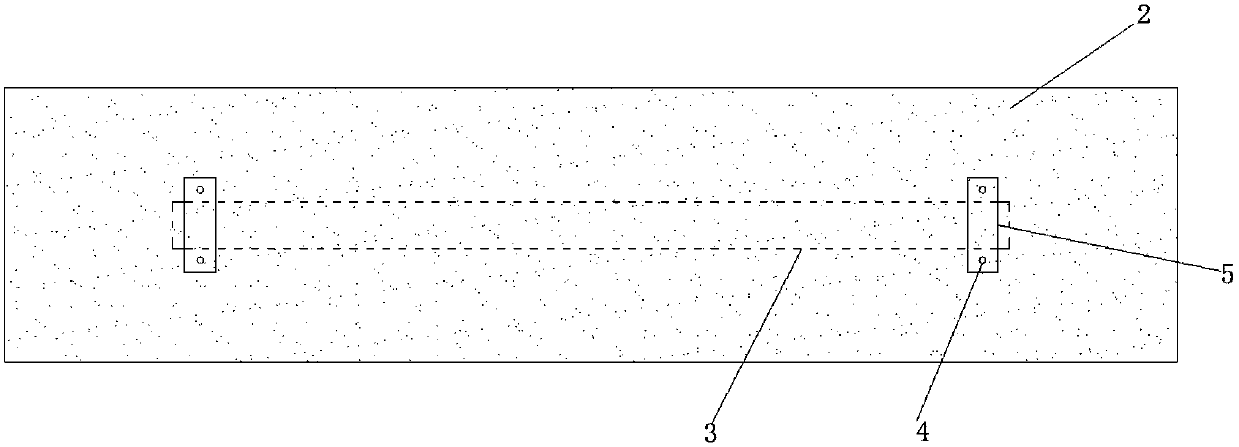

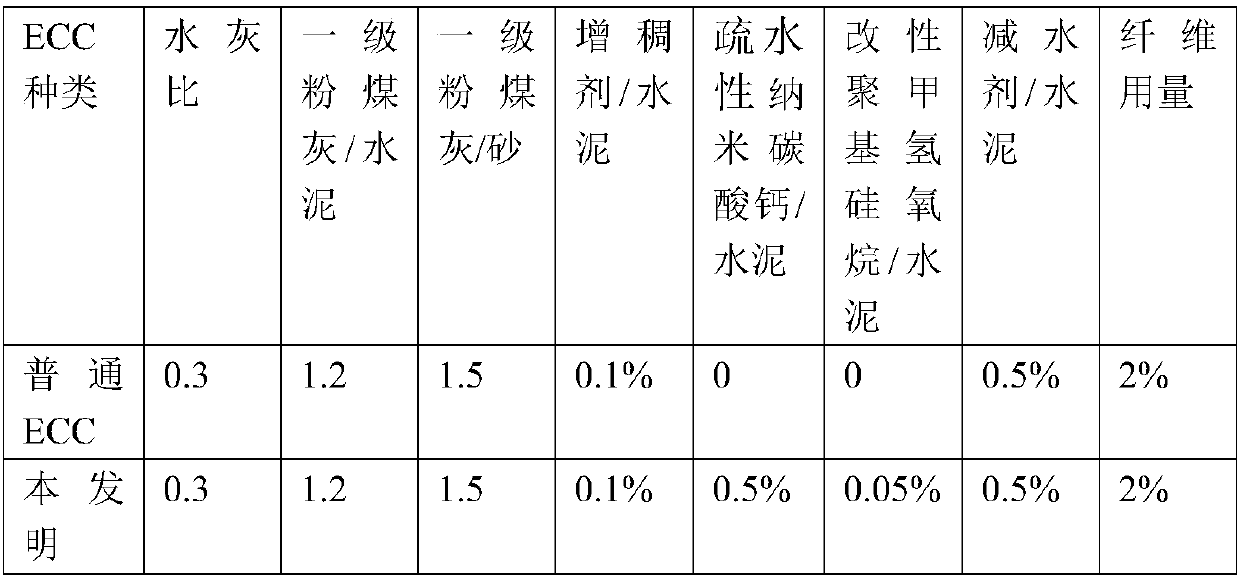

[0035] 1. The raw materials of ECC include cement, primary fly ash, silica sand, thickener, PVA fiber, water reducer, water, modified polymethyl hydrogen siloxane and other hydrophobic materials, as well as hydrophobic nano A class of hydrophobic nano-mineral materials such as calcium carbonate. The quality of cement is set as 1, the amount of primary fly ash is 1.0-1.5 times of the quality of cement, the amount of silica sand is 0.8-1.0 times of the quality of cement, the amount of thickener is 0.1%-0.15% of the quality of cement, and the water-cement ratio 0.3-0.45, the amount of water reducing agent is 0-0.5% of the cement amount, the volume of PVA fiber is 1.5%-2.5%, and the amount of a class of hydrophobic materials such as modified polymethylhydrogen siloxane is 2% of the cement quality 0.01%-0.1%, hydrophobic nano-calcium carbonate and other hydrophobic nano-mineral materials are added in an amount of 0.5%-1.5% of the cement mass.

[0036]2. ECC is mixed with a planeta...

Embodiment 2

[0040] 1. The raw materials of ECC include cement, primary fly ash, silica sand, thickener, PVA fiber, water reducer, water, modified polymethyl hydrogen siloxane and other hydrophobic materials, as well as hydrophobic nano A class of hydrophobic nano-mineral materials such as calcium carbonate. The quality of cement is set as 1, the amount of primary fly ash is 1.0 times of the quality of cement, the amount of silica sand is 0.8 times of the quality of cement, the amount of thickener is 0.1% of the quality of cement, the water-cement ratio is 0.3, and the amount of water reducer is The amount of cement is 0.1%, the volume of PVA fiber is 1.5%, the amount of a class of hydrophobic materials such as modified polymethylhydrogensiloxane is 0.01% of the cement mass, and a class of hydrophobic nano-calcium carbonate is The amount of mineral material is 0.5% of the cement mass.

[0041] 2. ECC is mixed with a planetary mortar mixer or a special ECC mixer. The feeding sequence and m...

Embodiment 3

[0045] 1. The raw materials of ECC include cement, primary fly ash, silica sand, thickener, PVA fiber, water reducer, water, modified polymethyl hydrogen siloxane and other hydrophobic materials, as well as hydrophobic nano A class of hydrophobic nano-mineral materials such as calcium carbonate. The quality of cement is set as 1, the amount of primary fly ash is 1.5 times of cement quality, the amount of silica sand is 1.0 times of cement quality, the amount of thickener is 0.15% of cement quality, the water-cement ratio is 0.45, and the amount of water reducing agent is The amount of cement is 0.5%, the volume of PVA fiber is 2.5%, the amount of a class of hydrophobic materials such as modified polymethylhydrogensiloxane is 0.1% of the cement mass, and a class of hydrophobic nanometers such as calcium carbonate is The amount of mineral material is 1.5% of the cement mass.

[0046] 2. ECC is mixed with a planetary mortar mixer or a special ECC mixer. The feeding sequence and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com