Carton anti-shape return integrated system combining die cutting and indentation with packaging

A die-cutting and indentation technology, which is applied in the field of carton die-cutting and indentation combined with packaging anti-back type integrated system, which can solve the problems of unfinished packaging and bending back stretching of a small section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] as attached figure 1 to attach Figure 7 Shown:

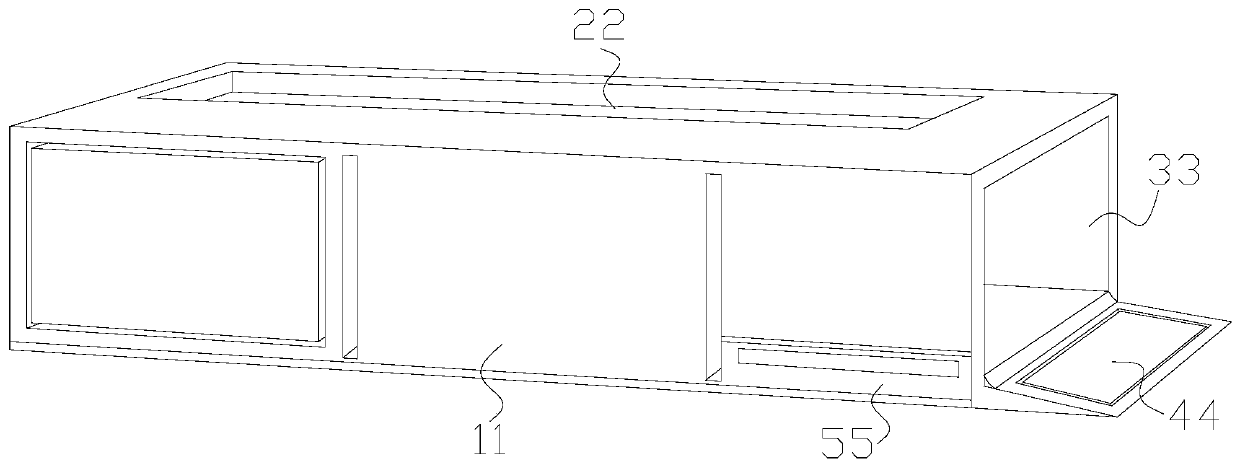

[0029] The present invention provides a carton die-cutting creasing combined packaging anti-return integrated system, the structure of which includes an automatic packing box 11, a headspace opening 22, an output gate 33, a buffer ramp 44, and a combined pressing track 55.

[0030] The combined pressure channel 55 is installed inside the automatic packing box 11, the headspace opening 22 runs through the inside of the automatic packing box 11, the output channel 33 and the headspace opening 22 are connected to each other, and the buffer ramp 44 is welded to the automatic packing box 11 Outer surfaces.

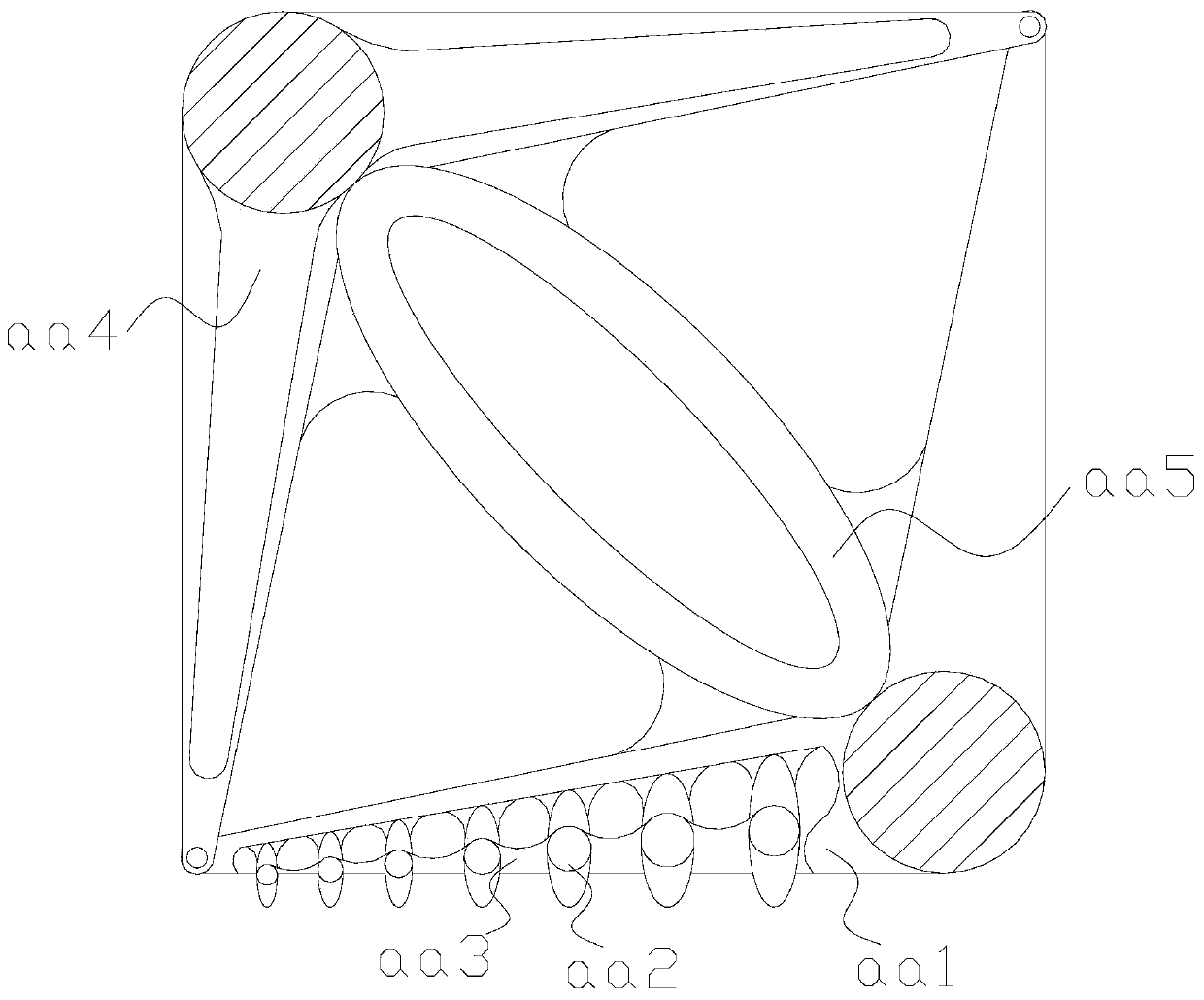

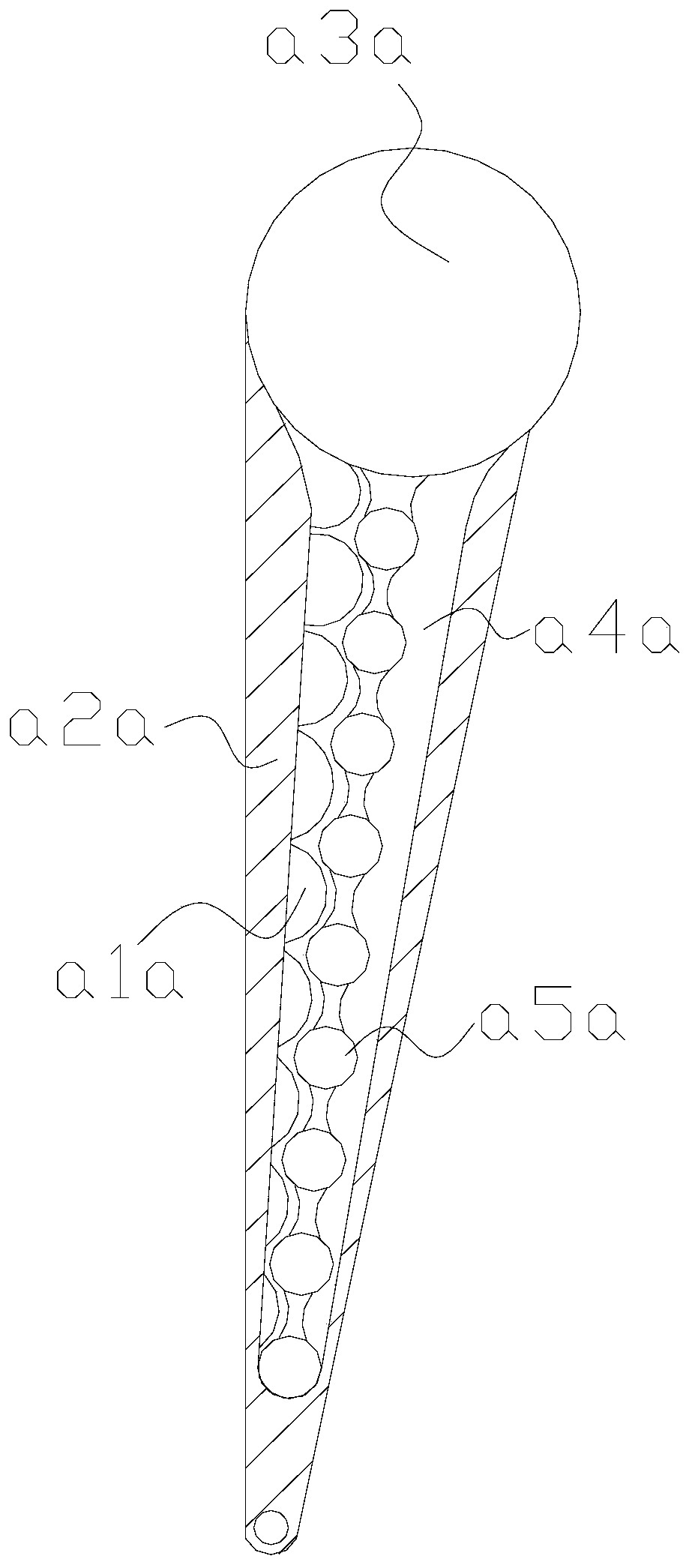

[0031] The merged pressure path 55 includes a clamping layer aa1, a ball aa2, an outer solid layer aa3, a vertical angle aa4, and an inner stretch ball aa5. The inner ball aa5 is against the outer surface of the vertical angle aa4, and the ball aa2 runs through Inside the outer solid layer aa3, the outer solid layer aa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com