A sheet coil inductance dispensing machine

A technology of sheet coil and glue dispenser, which is applied to spray devices, devices that apply liquid to surfaces, coatings, etc., can solve the problems of clogging of quick-drying glue, staleness, mixed glue, etc., and improve the sealing performance of the connection. , the damage rate reduction, the effect of protecting the persistence of fixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

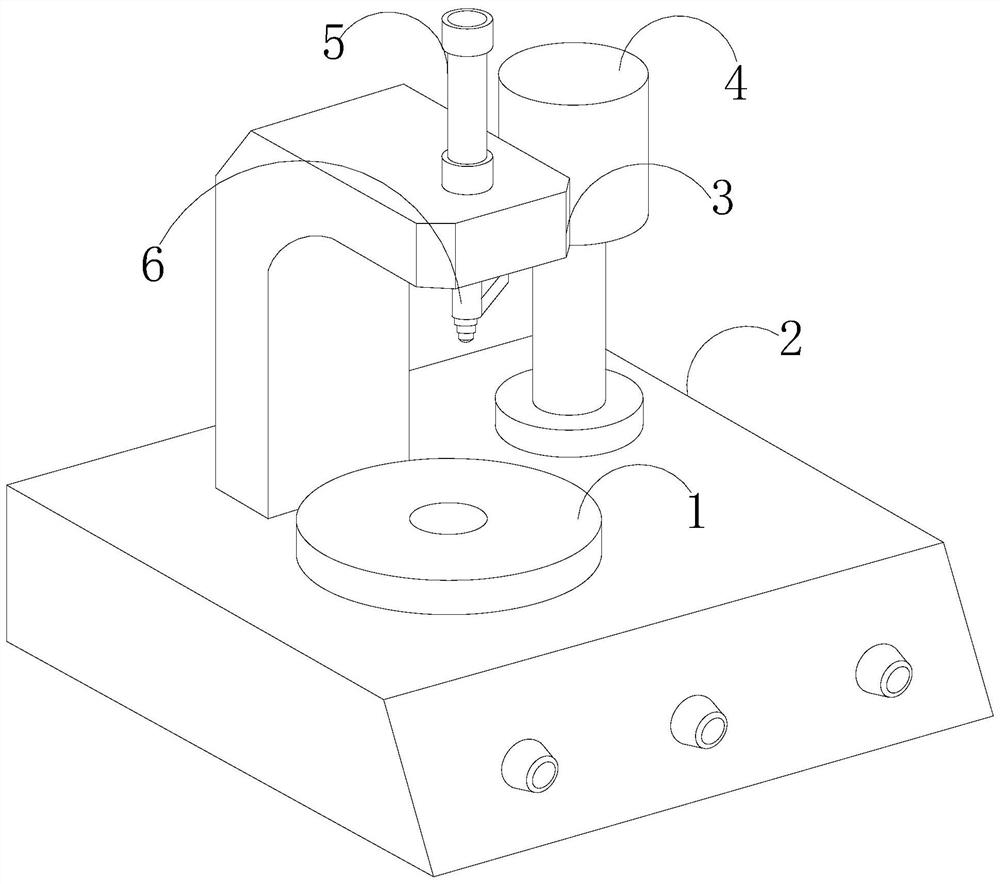

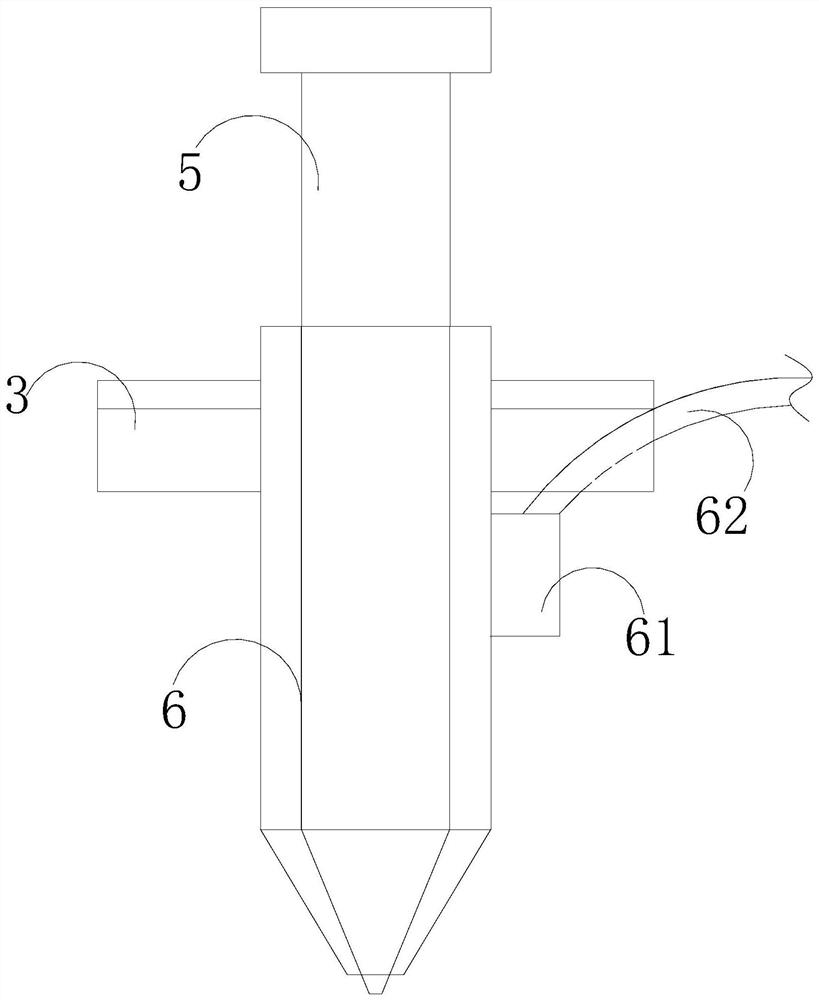

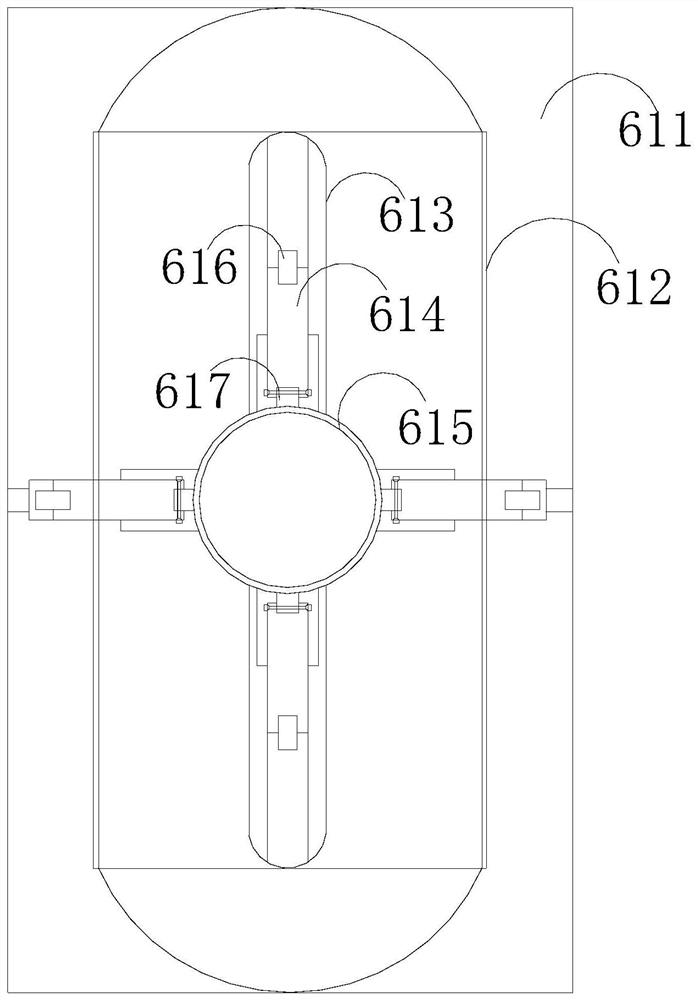

[0025] like Figure 1-Figure 6 As shown, the present invention provides a sheet coil inductance dispensing machine, the structure of which includes a storage carousel 1, a base 2, a mounting frame 3, a melt barrel 4, a drip stick cylinder 5, and a dispensing head 6. On the base 2, A storage carousel 1 and a mounting frame 3 are installed, and the mounting frame 3 is provided with a dripping cylinder 5 and a dispensing head 6, and the dripping cylinder 5 cooperates with the dispensing head 6, and the dispensing head 6 is connected with The pipeline auxiliary sleeve 61 and the connecting pipeline 62, the dispensing head 6 is connected with the melt glue barrel 4 through the connecting pipeline 62, the dispensing head 6 is up and down opposite to the storage carousel 1, and the connecting pipeline 62 is close to One side of the dispensing head 6 is provided with a pipeline auxiliary sleeve 61 .

[0026] The pipeline auxiliary cover 61 is provided with an outer protective cover b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com