Method suitable for bonding tension and compression pad of large-size large-load radome

A tension and pressure pad, large-scale technology, applied in the bonding method of adhesive heating, the bonding method of surface pretreatment, etc., can solve problems such as low efficiency, ensure bonding quality, save resources and plant space , The effect of saving test preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

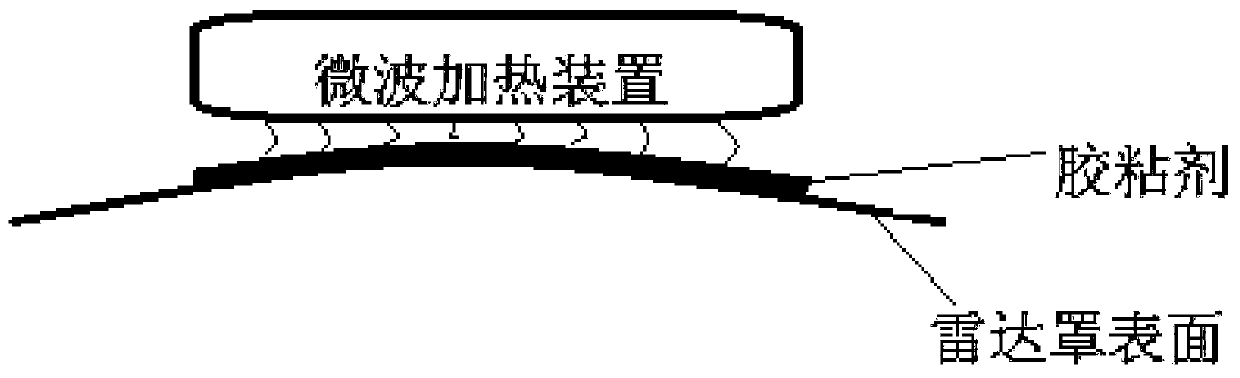

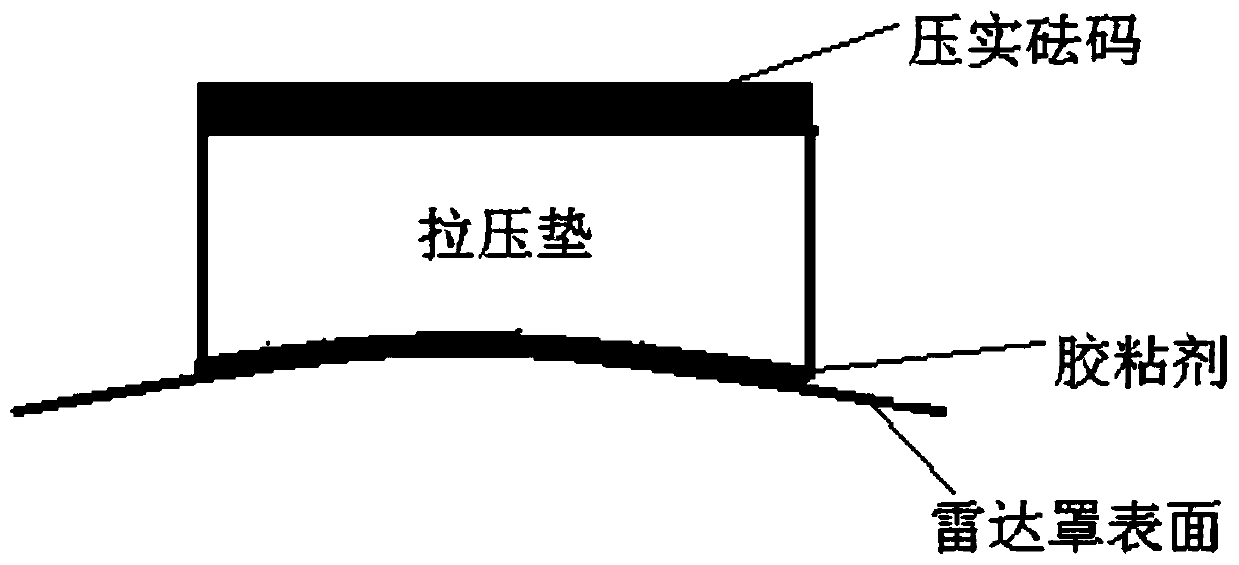

[0020] The existing method of natural drying and bonding of tension and pressure pads requires a long drying period, and the bonding quality is not high. Large size radome. Aiming at the above problems, the present invention designs a method of accelerated bonding of tension pads suitable for large-load and large-size radome. It does not need to repeatedly disassemble and transport the large-size radome, and accelerates the drying of the adhesive on the spot in real time. Improve bonding quality and test efficiency.

[0021] Specifically, a method suitable for bonding large-size and large-load radome tension and pressure pads, the method includes the following steps:

[0022] First, design and fabricate a conformal loading tension pad in the test area of the large-scale radome; in this step, the loading tension pad is completely attached to the loading area of the radome to ensure the authenticity of the loading;

[0023] Second, clean and polish the large-scale radome t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com