Floating type laser transmission welding clamping apparatus

A technology of laser transmission welding and clamping device, which is applied in the field of floating laser transmission welding clamping device and laser transmission welding clamping device, and can solve the problem of inability to realize three-dimensional welding seam welding, poor optical performance of glass ball, and surface of glass ball. Wear and other problems, to achieve the effect of reducing complexity, avoiding stress concentration and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

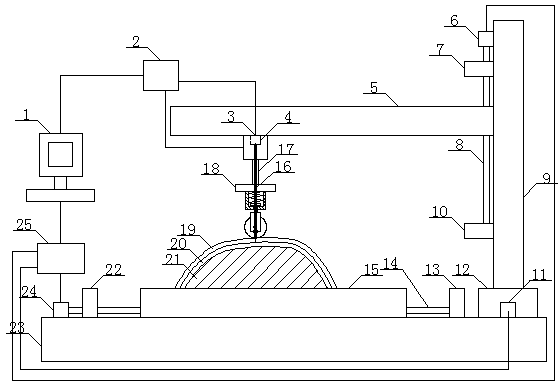

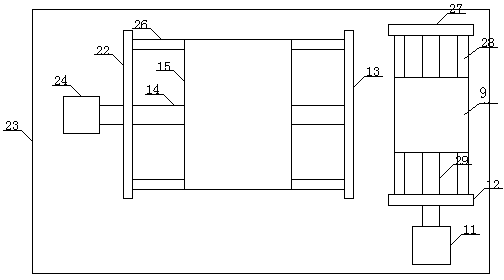

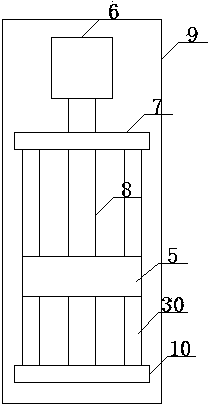

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] like Figure 1-5 shown.

[0029] A floating laser transmission welding clamping device, which includes a PC 1, a stepping motor control system 25, a bottom mold 21, an X, Y, and Z axis feed system, a pressure applying mechanism and a floating pressing mechanism, and the X axis feeds The feeding system moves the workbench 15 on which the upper workpiece 19, the lower workpiece 20 and the bottom mold 21 are installed to the X-axis welding starting position under the control of the stepping motor control system 25, and the Y-axis feeding system is controlled by the stepping motor. Under the control of the system 25, the right moving plate 9 drives the pressing mechanism and the floating pressing mechanism to move to the starting position of welding along the Y axis, and the PC 1 controls the pressing mechanism to apply a set pre-pressure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com