Homogenizing device

A technology of leveler and feed port, which is applied in application, poultry industry, animal husbandry, etc., can solve the problems of poor leveling effect of the leveler, and achieve the effect of novel structure, convenient and quick operation, and prevention of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

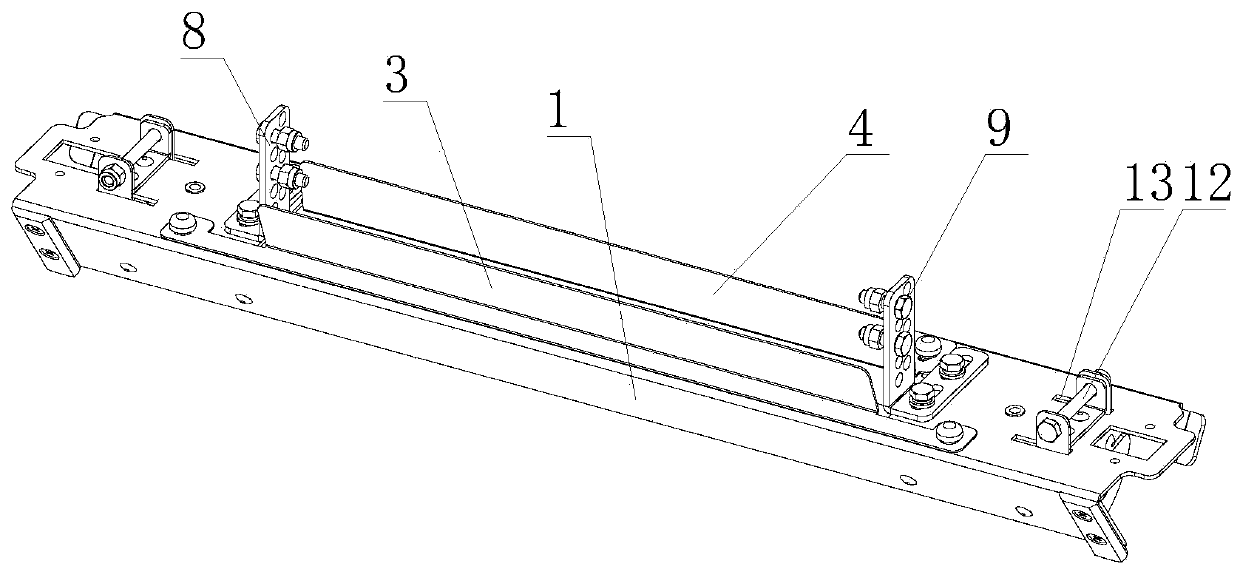

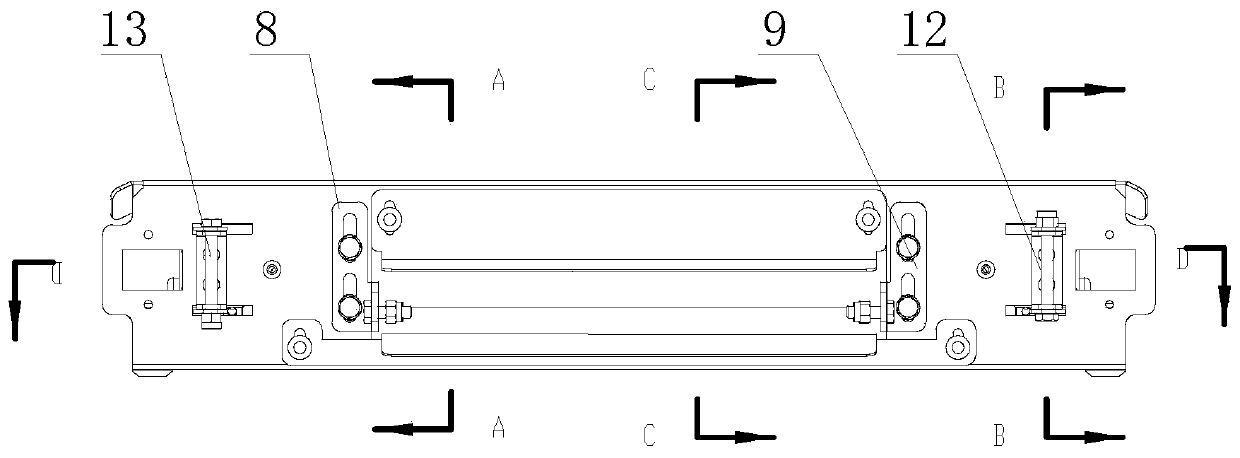

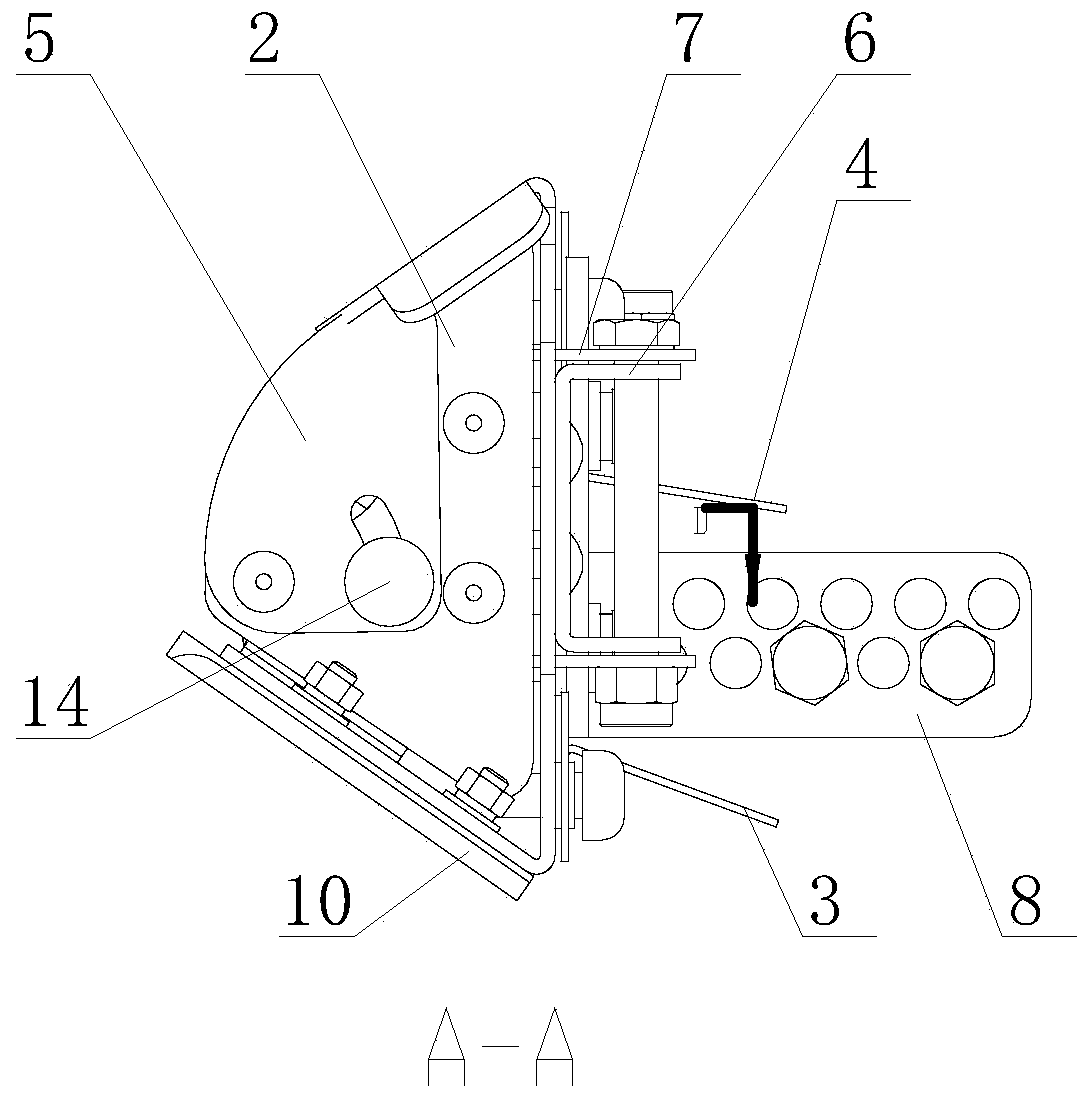

[0029] Such as Figure 1 to Figure 10 As shown, the homogenizer includes a homogenizer main body 1, the upper panel of the homogenizer main body 1 is provided with a homogenization port corresponding to the food trough, and inner baffles 4 extending downwards are installed on the inner and outer sides of the homogenization port. Cooperating with the outer baffle 3, the outer baffle 3 and the inner baffle 4 play the role of preventing the chicken feed in the homogenizer from overflowing the homogenizer.

[0030] The left and right ends of the upper panel of the homogenizer main body 1 are equipped with a homogeneous material component, which is a valve for controlling discharge, and one group is respectively arranged along the left and right sides of the homogenizer main body 1 . The leveling assembly includes suspension ears 6, scraper suspension ears 7, and scraper 2. The suspension ears 6 are fixedly installed on the upper panel of the homogenizer main body 1, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com