Sealant supplementing method and device for LED display screen lamp panel module and application method of sealant supplementing device

A technology of LED display and module, which is applied to the device for coating liquid on the surface, identification device, coating, etc., can solve the problems of not moving too fast, high viscosity of sealing glue, affecting the quality of LED display, etc. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the examples.

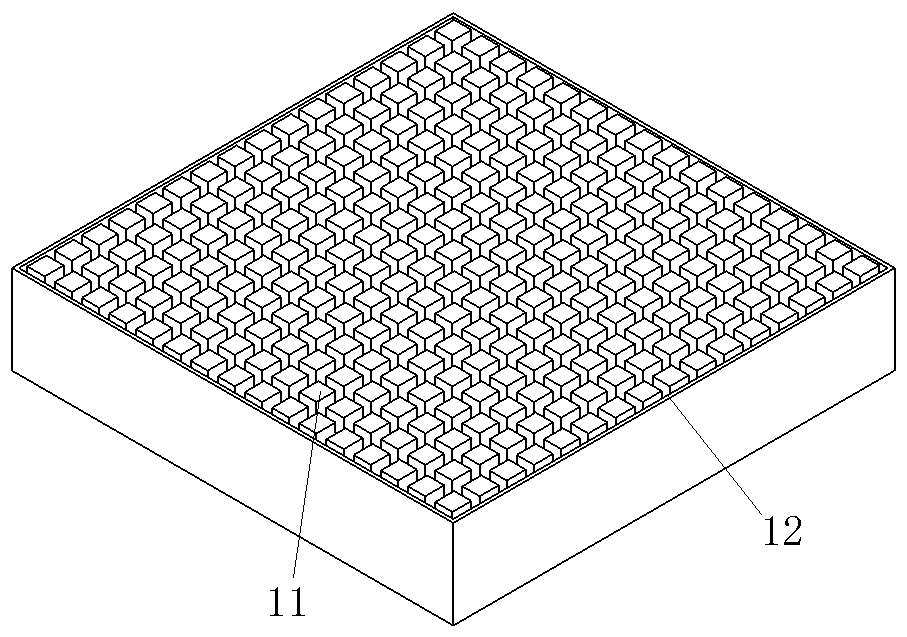

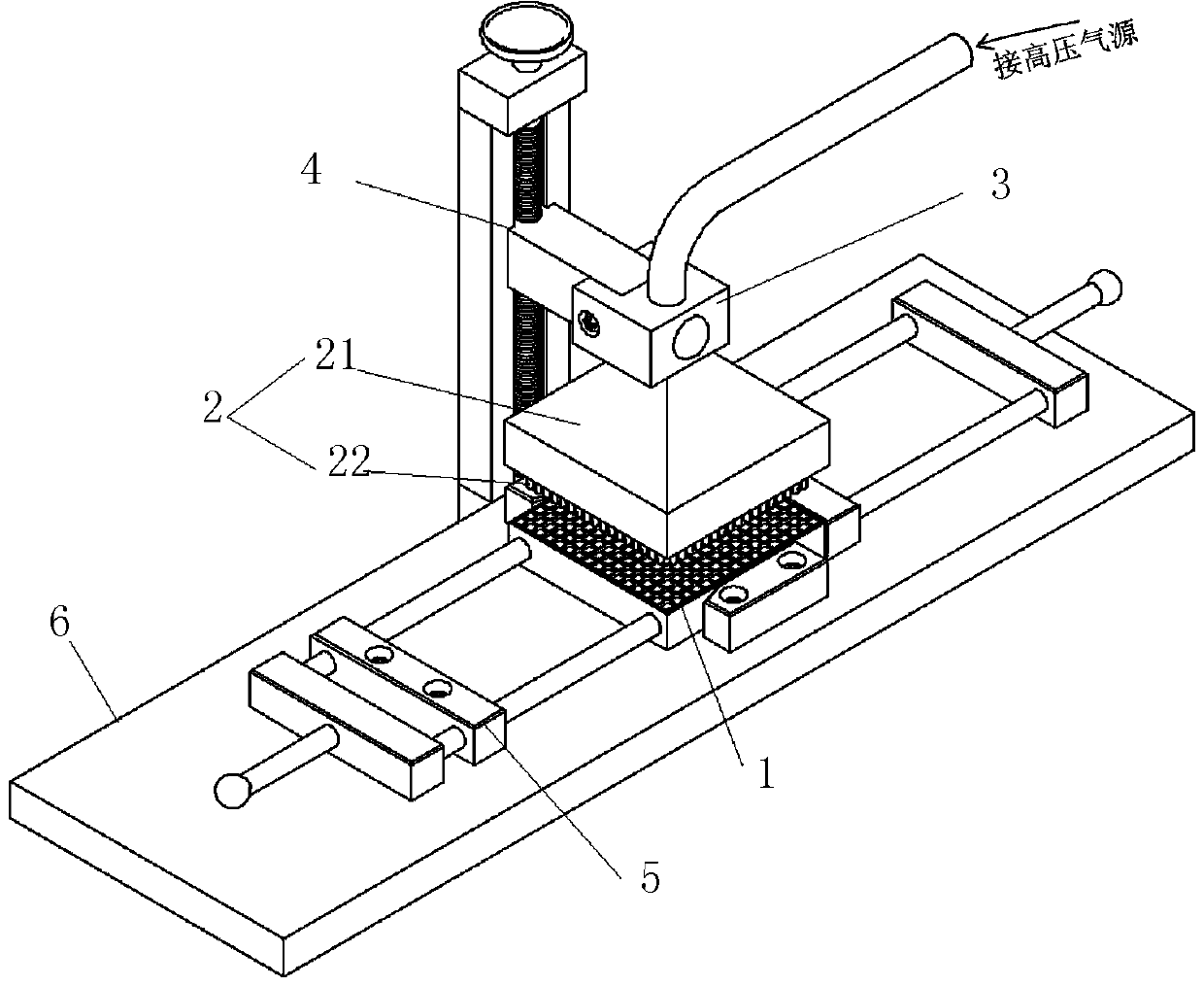

[0026] see Figure 1-Figure 3 , a glue replenishing device for LED display panel modules, the glue replenishing device includes an air jet part, a module fixing part, a lifting mechanism, and an air jet head holder 3,

[0027] The module fixing part is used to fix the LED display lamp panel module, including the base 6 and the module clamp 5 arranged on the base 6,

[0028] The lifting mechanism in this embodiment is a screw slider mechanism 4, the screw slider mechanism 4 is installed on the base 6, the screw is vertically arranged, and the air nozzle holder 3 is installed on the slider.

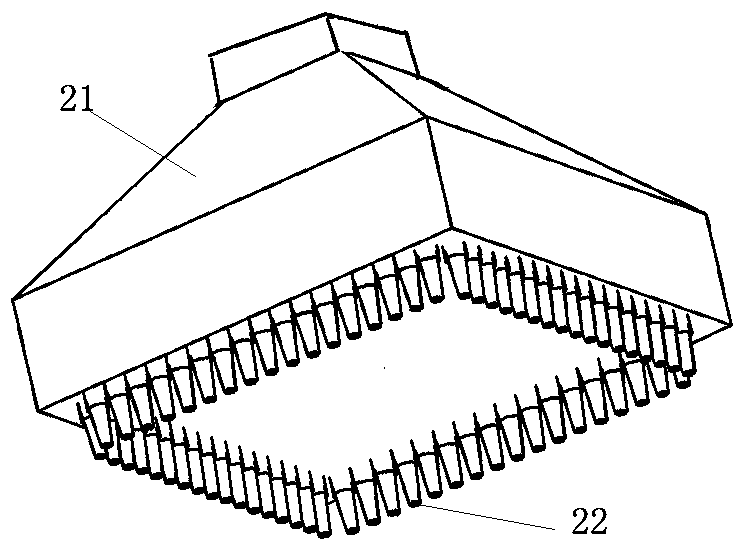

[0029] The air injection parts include a high-pressure air source, an air injection head 2, and the air injection head 2 includes an air gathering chamber 21 and an air nozzle 22. The air gathering chamber 21 has a small upper part and a larger lower part in a conical shape, and the top of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap