A position-adjustable handle rod and steering handle of agricultural machinery

A technology for steering handles and agricultural machinery, which is applied to the steering control and handlebars installed on the vehicle. It can solve the problems that the position of the handle bar cannot be adjusted, cannot meet the driver's manipulation needs, and misuse, etc., so as to achieve convenient one-handed operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

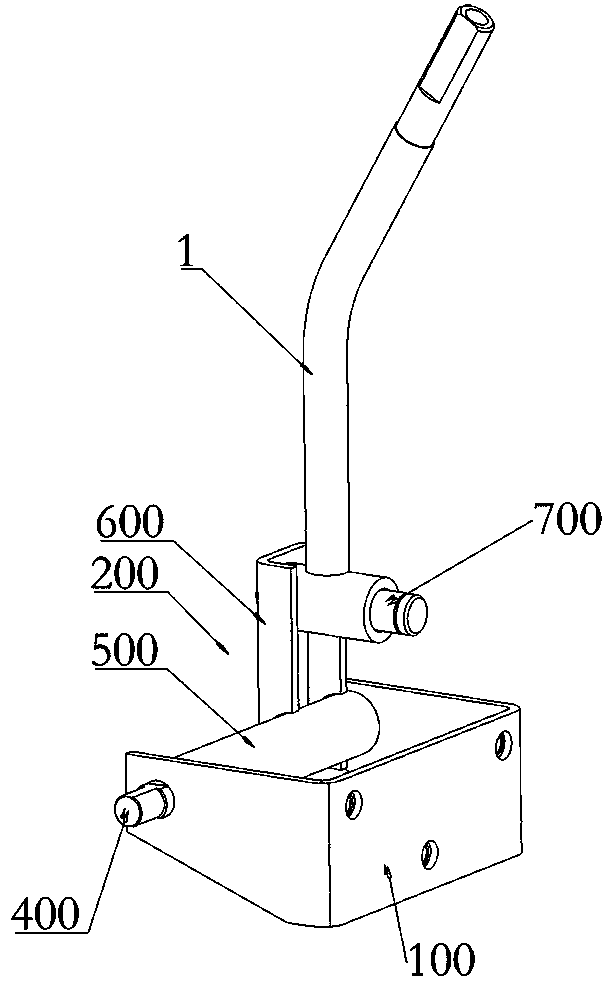

[0049] figure 1 and figure 2It is a structural schematic diagram of a handle bar of an existing agricultural motor vehicle, which can realize front, rear, left, and right direction manipulation.

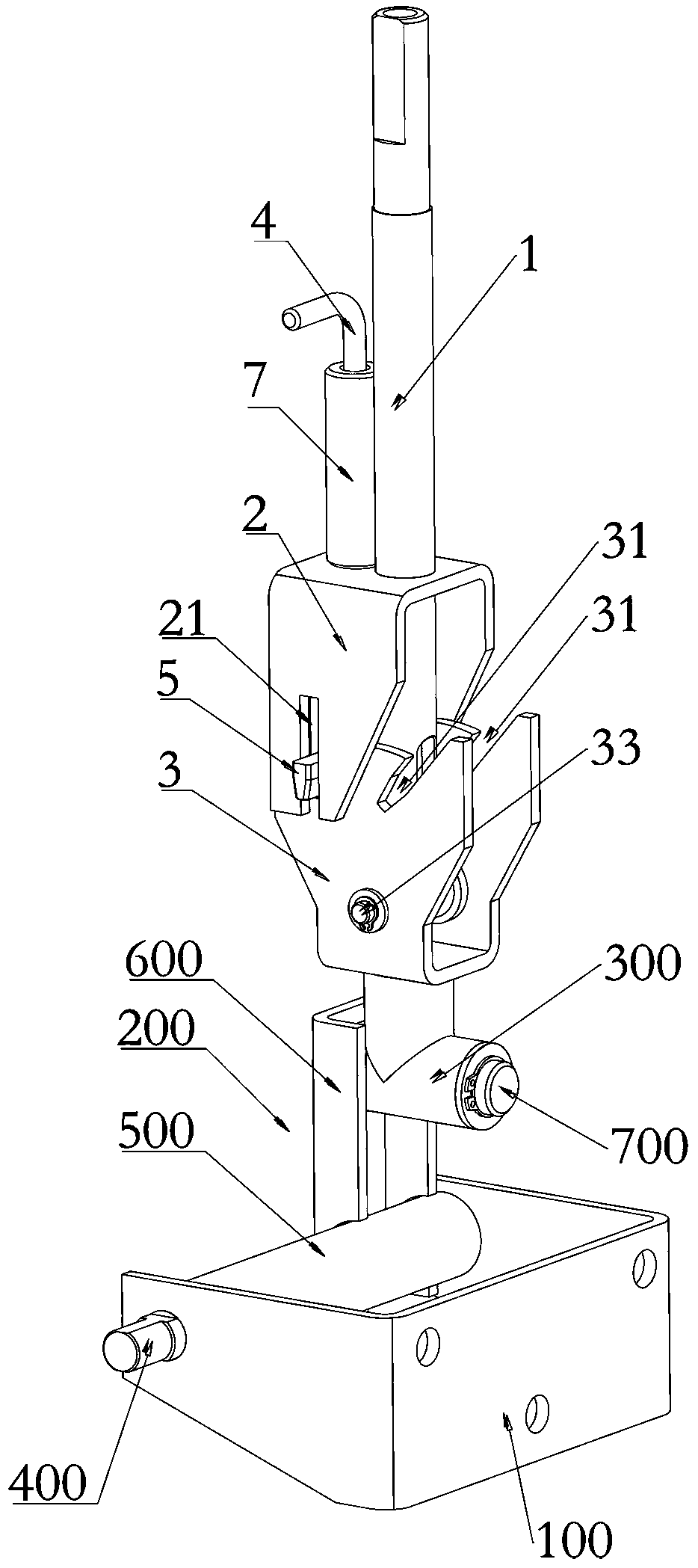

[0050] Such as Figure 3-Figure 12 As shown, a position-adjustable handle rod of this embodiment includes a handle rod welded 1, a limit bracket 2, a rotating support 3, a pull rod 4 and a limit pin 5, and the lower end of the handle rod welded 1 is hinged On the rotating support 3, the limit bracket 2 is fixed on the middle part of the handle rod welding 1, the limit bracket 2 is provided with a guide groove 21, and the pull rod 4 is movably arranged in the limit position. On the bracket 2 and arranged side by side with the handle bar welded 1, the lower end of the pull rod 4 is provided with a limit pin 5, and the limit pin 5 is elastically connected to the limit bracket 2 and is located in the guide groove 21 ; The rotating support 3 is provided with a number of limit grooves ...

Embodiment 2

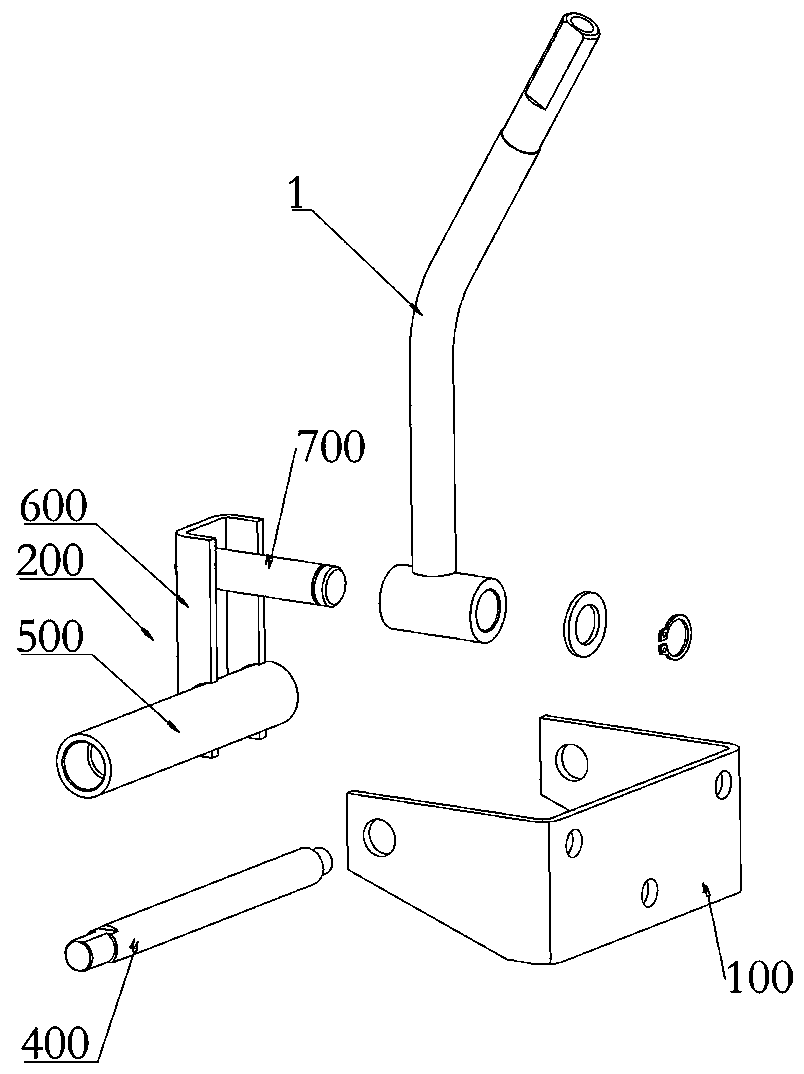

[0069] Such as Figure 3-Figure 12 As shown, a steering handle for agricultural machinery in this embodiment includes a fixed seat 100, a rotating seat welded 200 and the handle rod, and the bottom of the rotating support 3 is installed with a welded 1 vertically arranged with the handle rod. The second shaft sleeve 300; the first shaft 400 is installed on the fixed seat 100; the rotation seat welding 200 includes a third shaft sleeve 500, a connecting rod 600 and a second shaft 700, and the third shaft sleeve 500 and the second rotating shaft 700 are vertically connected to the connecting rod 600 respectively, the third bushing 500 and the second rotating shaft 700 are mutually misaligned and arranged vertically; the second bushing 300 is sleeved on the On the second rotating shaft 700 , the third sleeve 500 is sleeved on the first rotating shaft 400 .

[0070] The steering handle of this embodiment can switch between different operating angles according to the needs of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com