Cable built-in electric lifting stand column

A lifting column, built-in technology, applied in the direction of the lifting device, etc., can solve the problems of dense cables, interference with the lifting of the electric lifting table, messy cables, etc., and achieve the effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

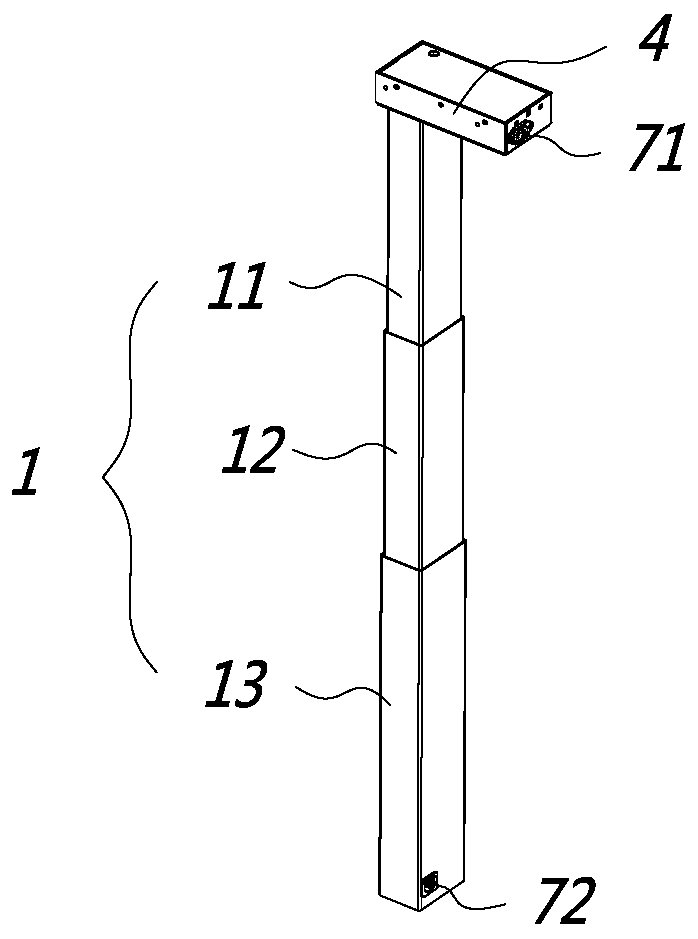

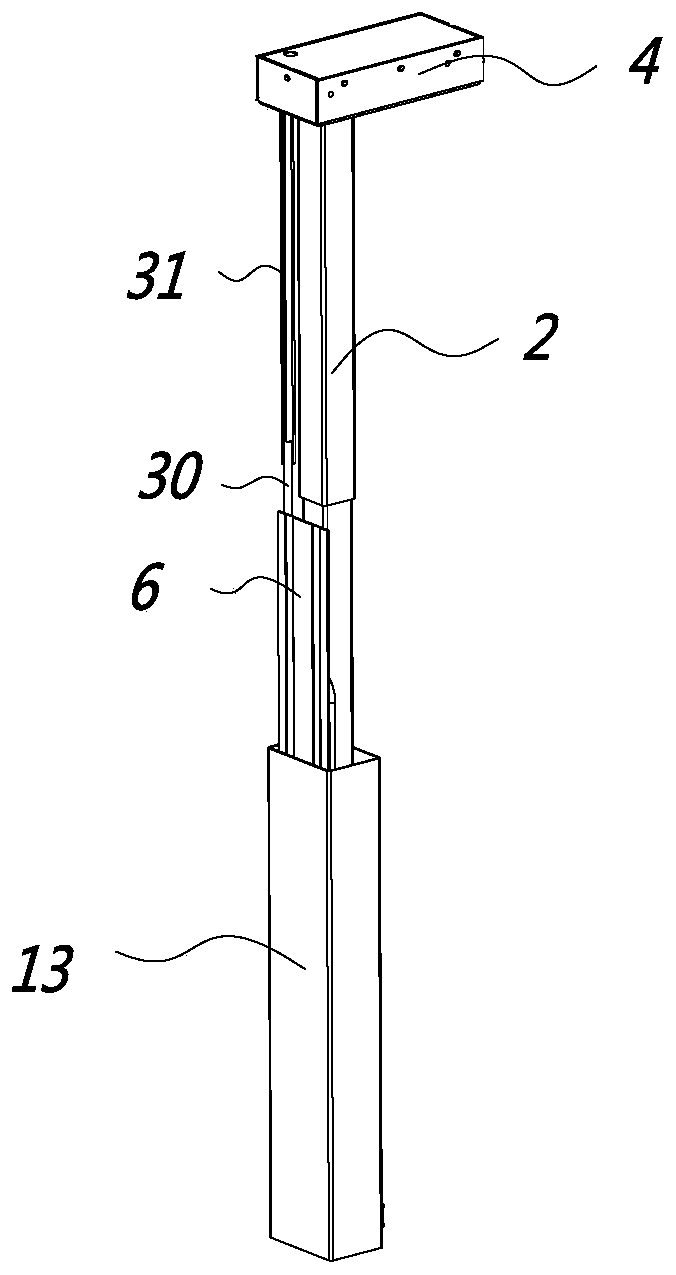

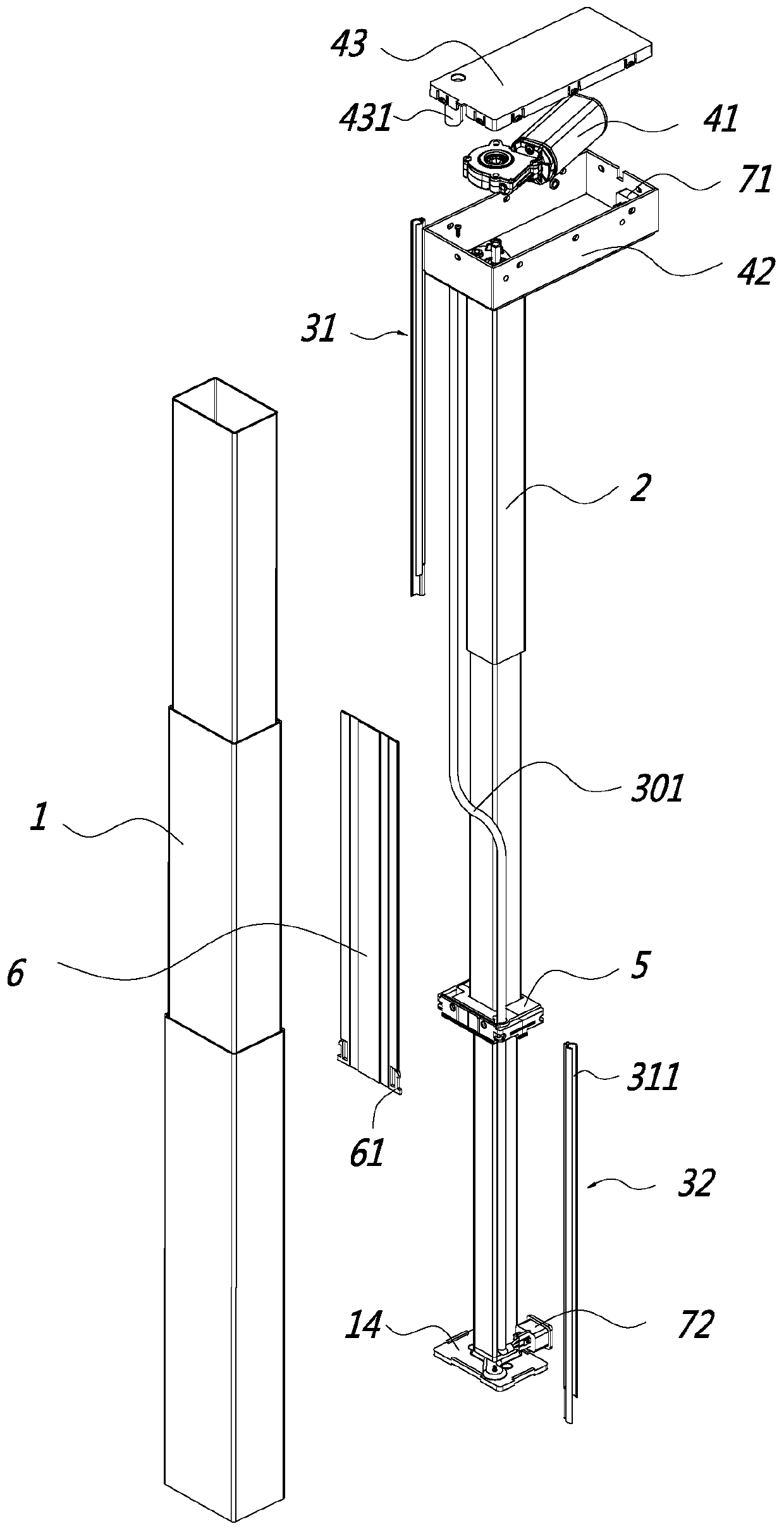

[0030] Such as Figure 1 to Figure 4 As shown, this embodiment shows an electric lifting column, which includes a telescopic sleeve member 1, and the telescopic sleeve member 1 includes at least a first sleeve 11 and a second sleeve 12. Of course, it may also include a third sleeve. Pipes, fourth sleeves, etc., the three-section electric lifting column shown in this embodiment includes a first sleeve 11, a second sleeve 12, and a third sleeve 13. The telescopic sleeve member 1 is provided with Transmission assembly 2. The transmission assembly 2 drives the first sleeve 11 and the second sleeve 12 to expand and contract relatively. For the structure of the transmission assembly 2, it mainly includes a transmission screw, a transmission nut and other structural components. When the screw rotates, it drives the transmission nut to move up and down, and the transmission nut drives the telescopic sleeve member 1 to expand and contract. Since the structure of the transmission assembl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com