Patents

Literature

43results about How to "Reduce the chance of entanglement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

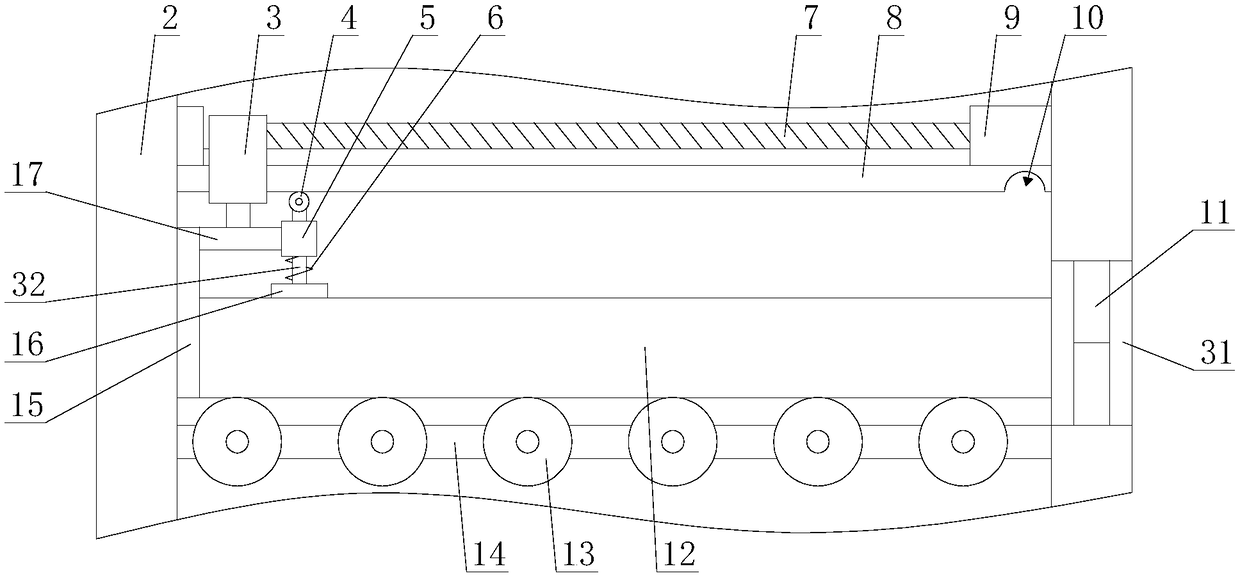

Rotary cultivator used for large-scale cultivation

The invention relates to the technical field of agricultural machines, and discloses a rotary cultivator used for large-scale cultivation. The rotary cultivator comprises a fixed frame, fixed blocks are fixedly installed on one side of the top end of the fixed frame, a first rotary shaft is movably sleeved with the tops of the first fixed blocks, a first gear fixedly sleeves the middle of the outer side of the first rotary shaft, a second gear is fixedly installed at one end of the first rotary shaft, a second fixed block is fixedly installed in the middle of the front face of the fixed frame,a second rotary shaft is movably sleeved with the top of the second fixed block, and an end face gear is fixedly installed on the back face of the second rotary shaft. According to the rotary cultivator used for large-scale cultivation, drive gears, first driving gears and second driving gears are installed on the two sides of the fixed frame respectively, accordingly, power of the rotary cultivator is transmitted and moved to the two sides of the fixed frame, the two ends of a third rotary shaft and the two ends of a fourth rotary shaft are stressed more evenly, the loss of a single drive set is reduced, and cultivation blind regions of the rotary cultivator are effectively reduced.

Owner:杜海碧

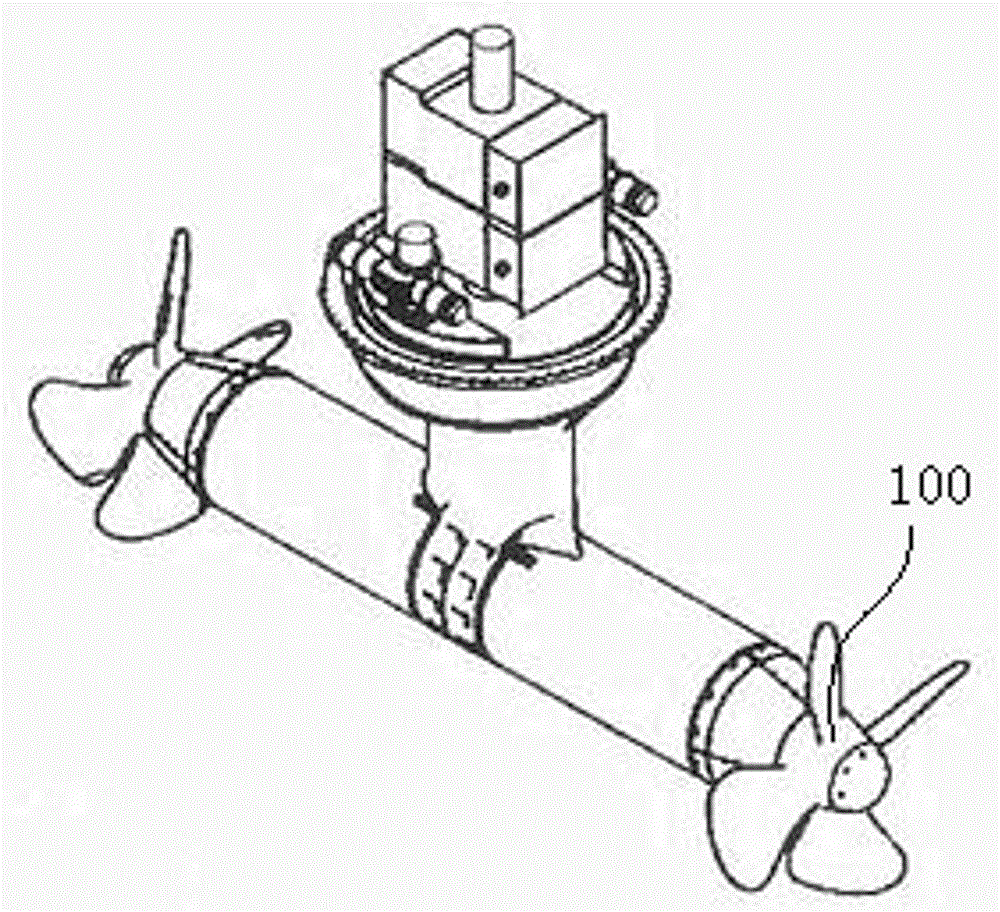

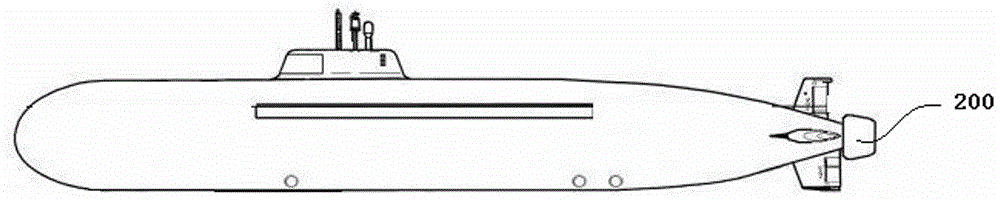

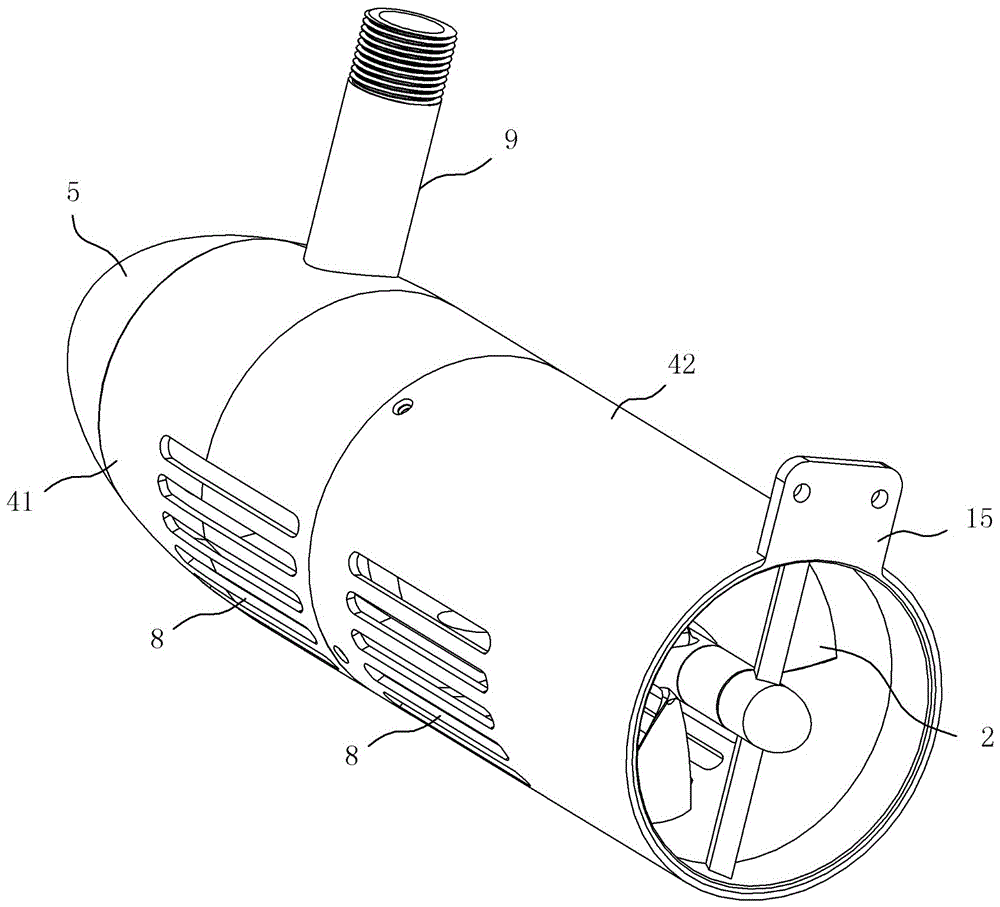

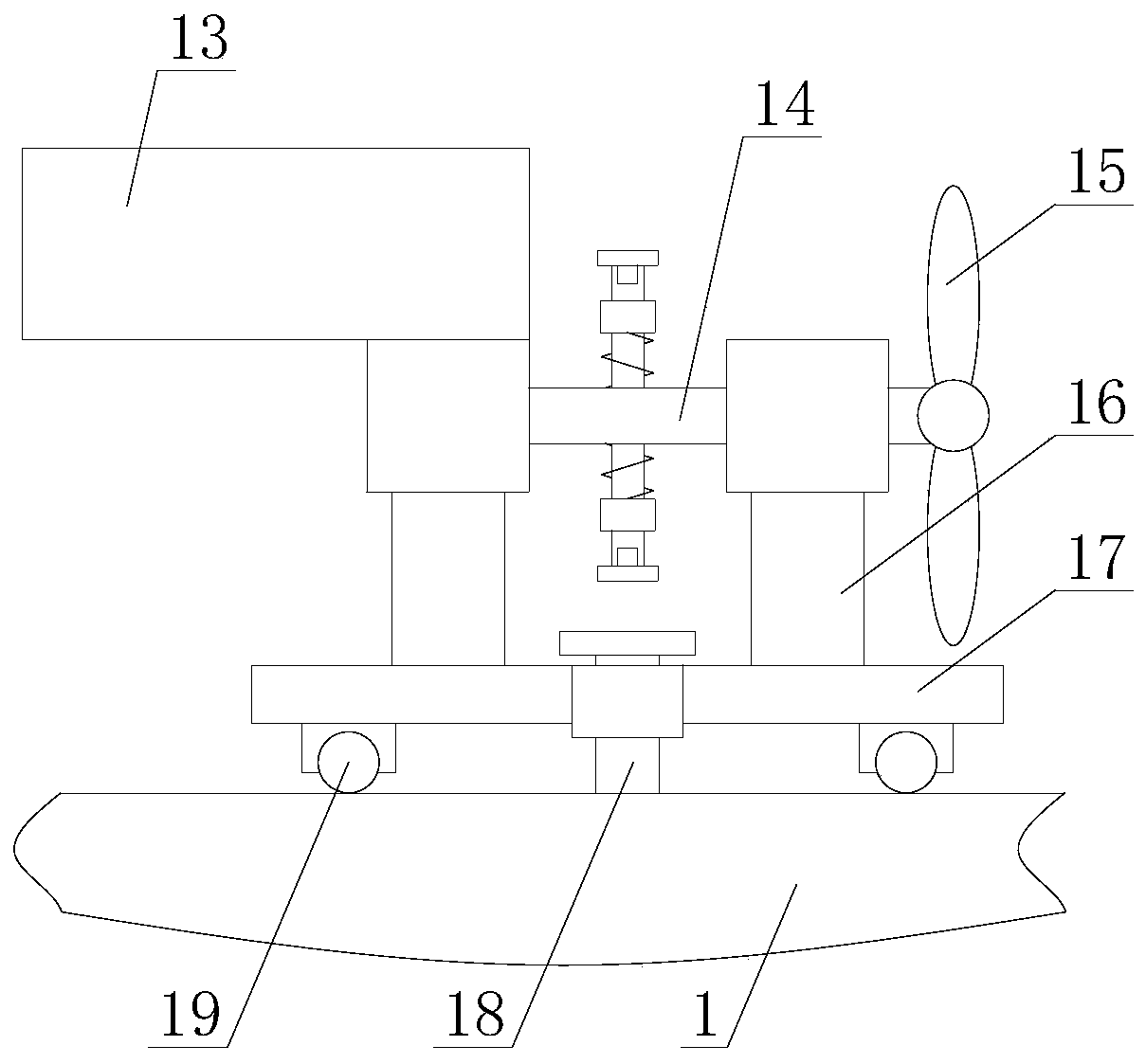

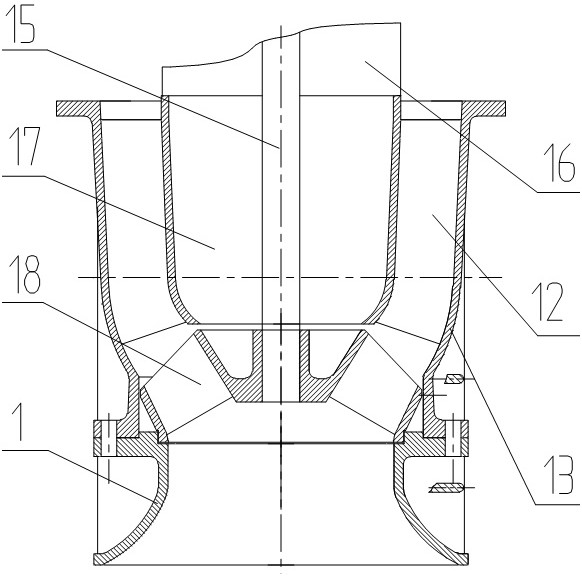

Pipeline thruster with protection function

InactiveCN106143849AReduce cavitationConcentration of waterRotary propellersPropulsion power plantsPropellerDrive motor

The invention provides a pipeline thruster with a protection function. A drive motor, a propeller and a rotary shaft are installed in a flow guide pipe. The outer portion of the drive motor is sealed through a motor shell and an axle housing. Strip-shaped through grooves are formed in the flow guide pipe. Water flow enters the flow guide pipe through the strip-shaped through grooves and is driven by the propeller to generate counter acting force to push a ship to move. By the adoption of the thruster, the work efficiency of equipment can be improved, the propeller is effectively protected, meanwhile, the strip-shaped through grooves in the flow guide pipe can make a water body circulate, can protect equipment operation and further can act together with the motor shell to achieve the effective water cooling and heat dissipation effects on the drive motor, and the equipment structure is greatly simplified.

Owner:珠海蓝创科技有限公司

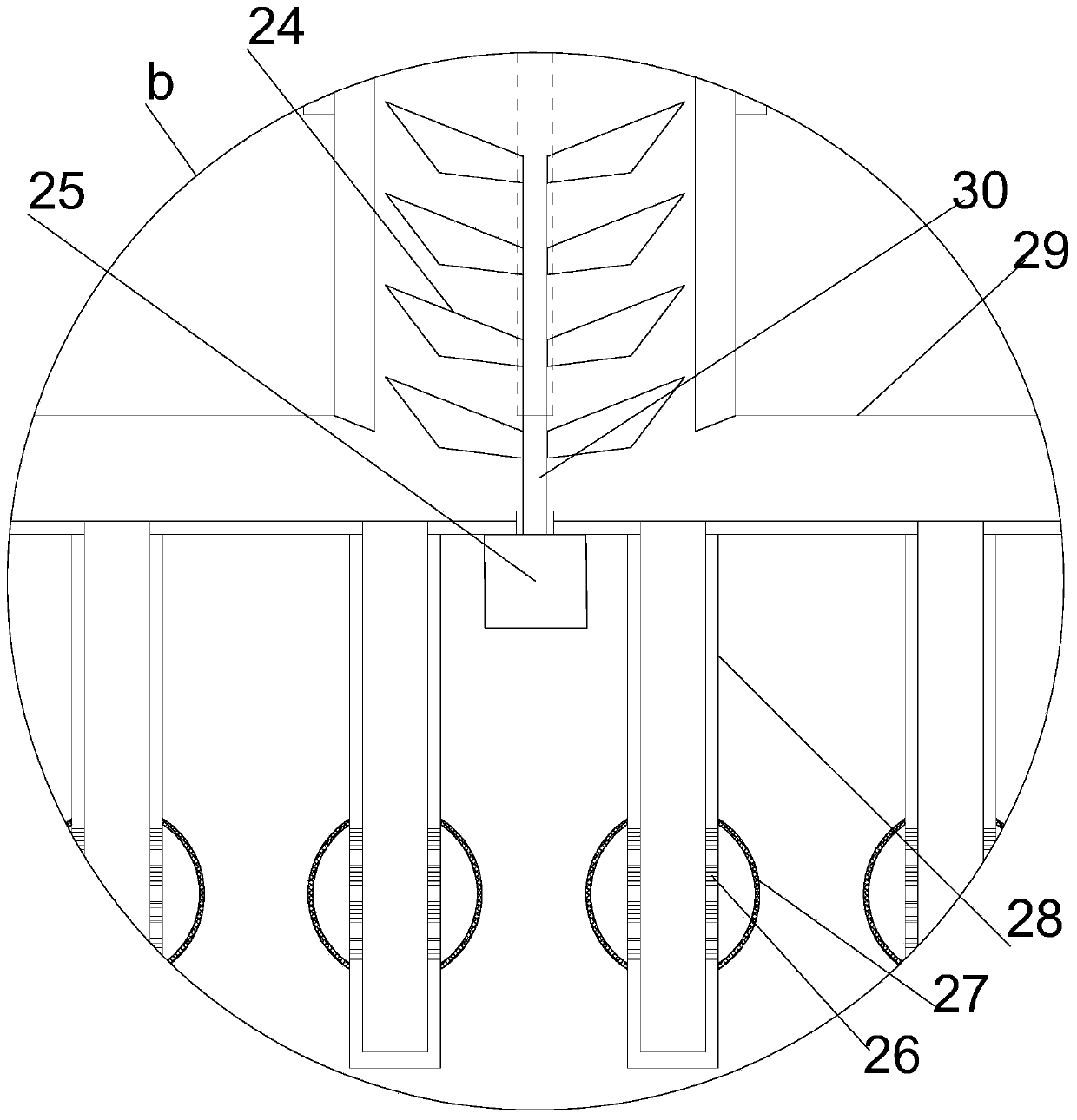

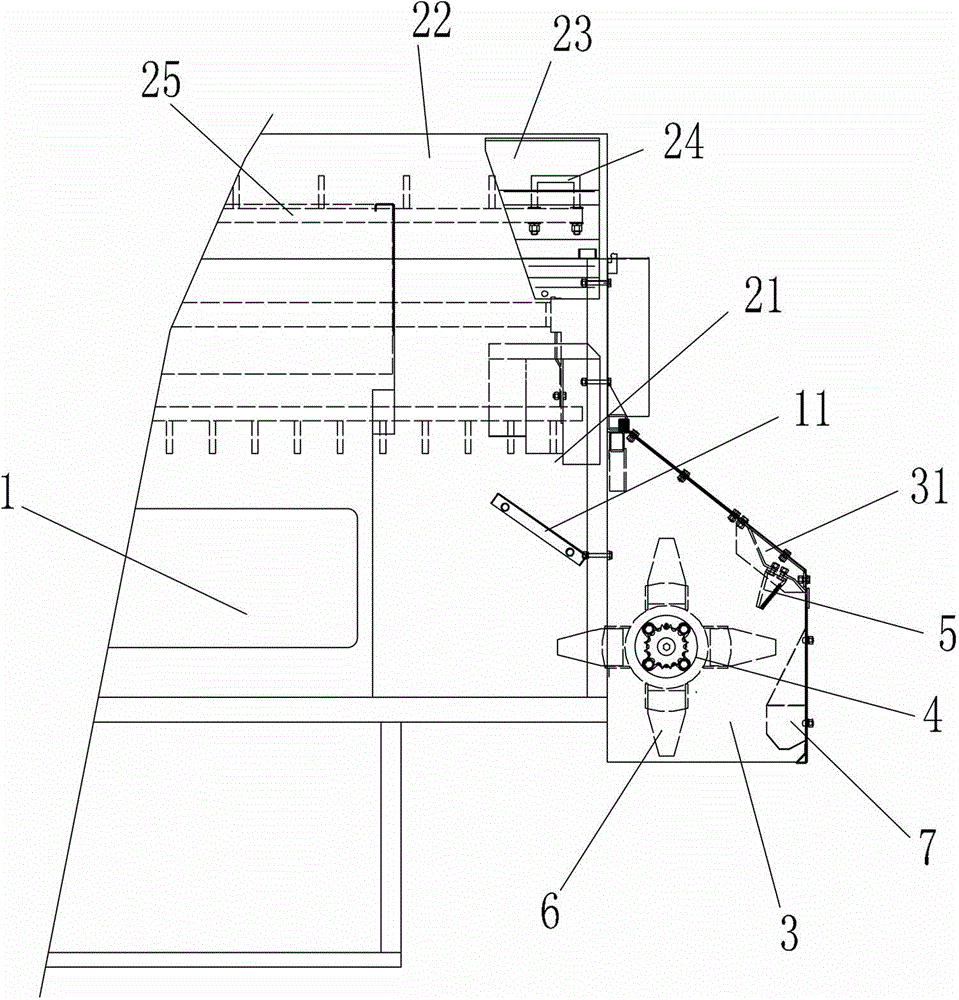

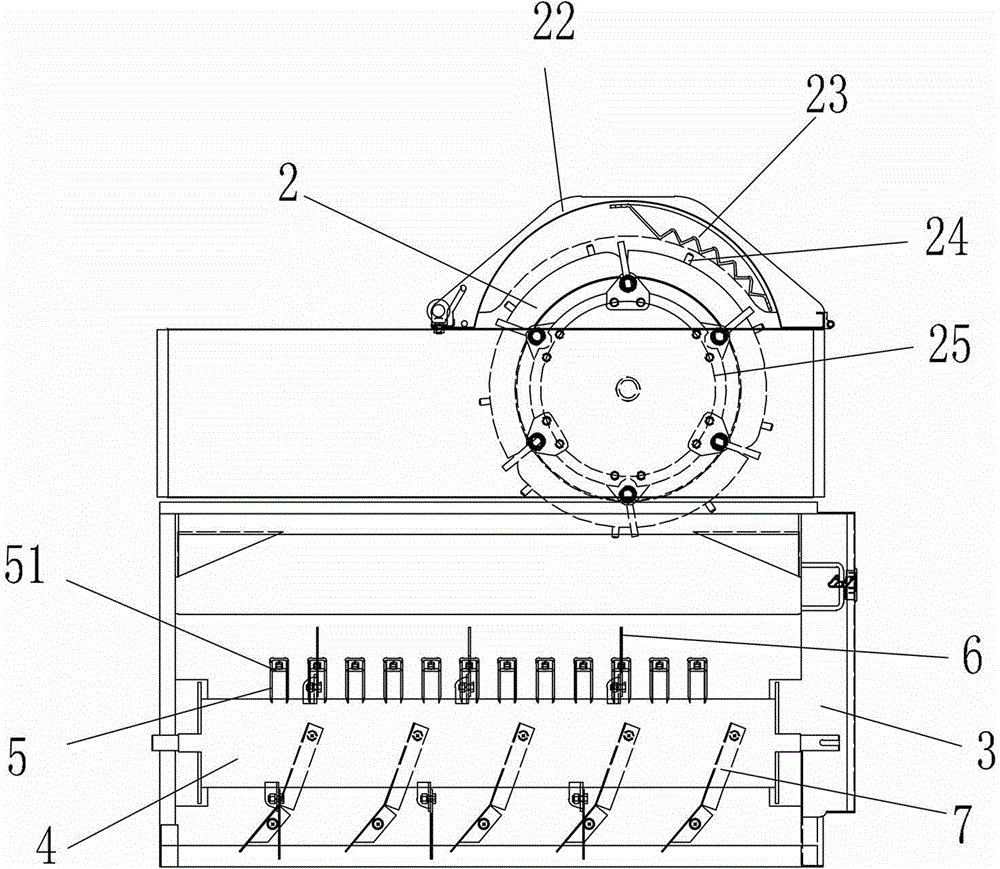

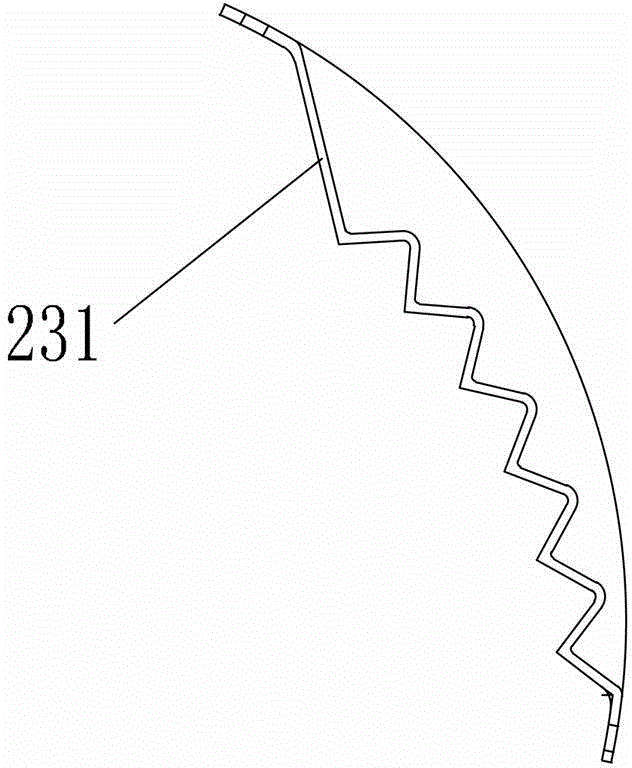

Novel combined harvester shredding device

The invention relates to the field of harvesters, in particular to a novel combined harvester shredding device. The novel combined harvester shredding device comprises a weed smashing rubbing plate arranged at the rear end of a top cover, rubbing teeth arranged on a tooth frame and matched with the weed smashing rubbing plate, and a weed smashing cutter assembly arranged below a material outlet. The weed smashing cutter assembly comprises a discharging frame arranged at the rear end of the rack, a frame cover arranged on the discharging frame, a discharging cavity located below the frame cover, a discharging cylinder arranged on the discharging frame and located in the discharging cavity, fixed cutters and movable cutters, wherein the fixed cutters are arranged on the discharging frame, and the movable cutters are arranged on the discharging cylinder. The material outlet is communicated with the discharging cavity, and a discharging port is formed in the bottom of the discharging frame. Through movement inertia of a threshing cylinder, straw or weeds to be discharged out are shredded through the rubbing force of the teeth and the rubbing plate for the first time and then separated. The straw or the weeds fall to be conveyed to the weed smashing cutter assembly to be shredded at last through the shredding action of the movable cutters and the fixed cutters, and then the straw or the weeds are discharged through the discharging port. The novel combined harvester shredding device is simple in structure, low in cost, convenient to install, good in shredding effect, low in weed winding rate and high in shredding efficiency.

Owner:曾联

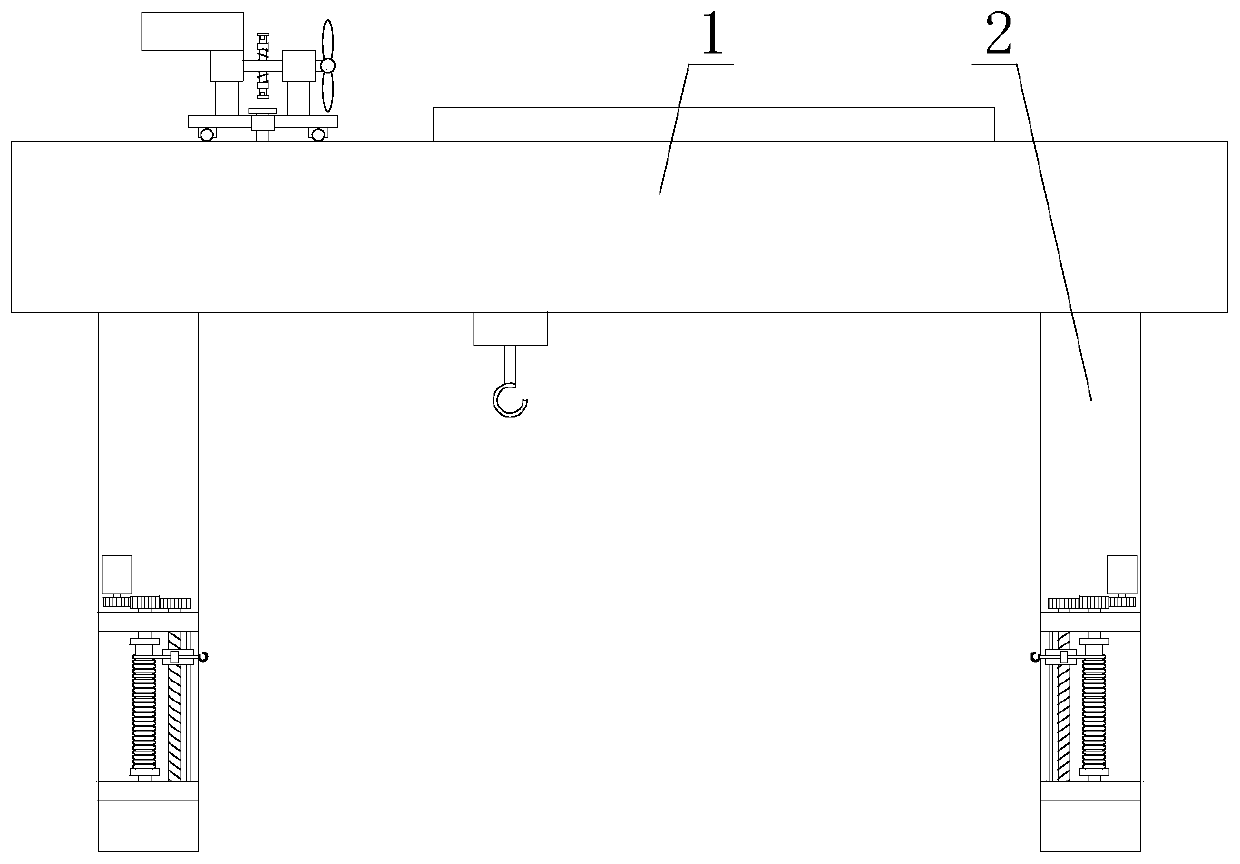

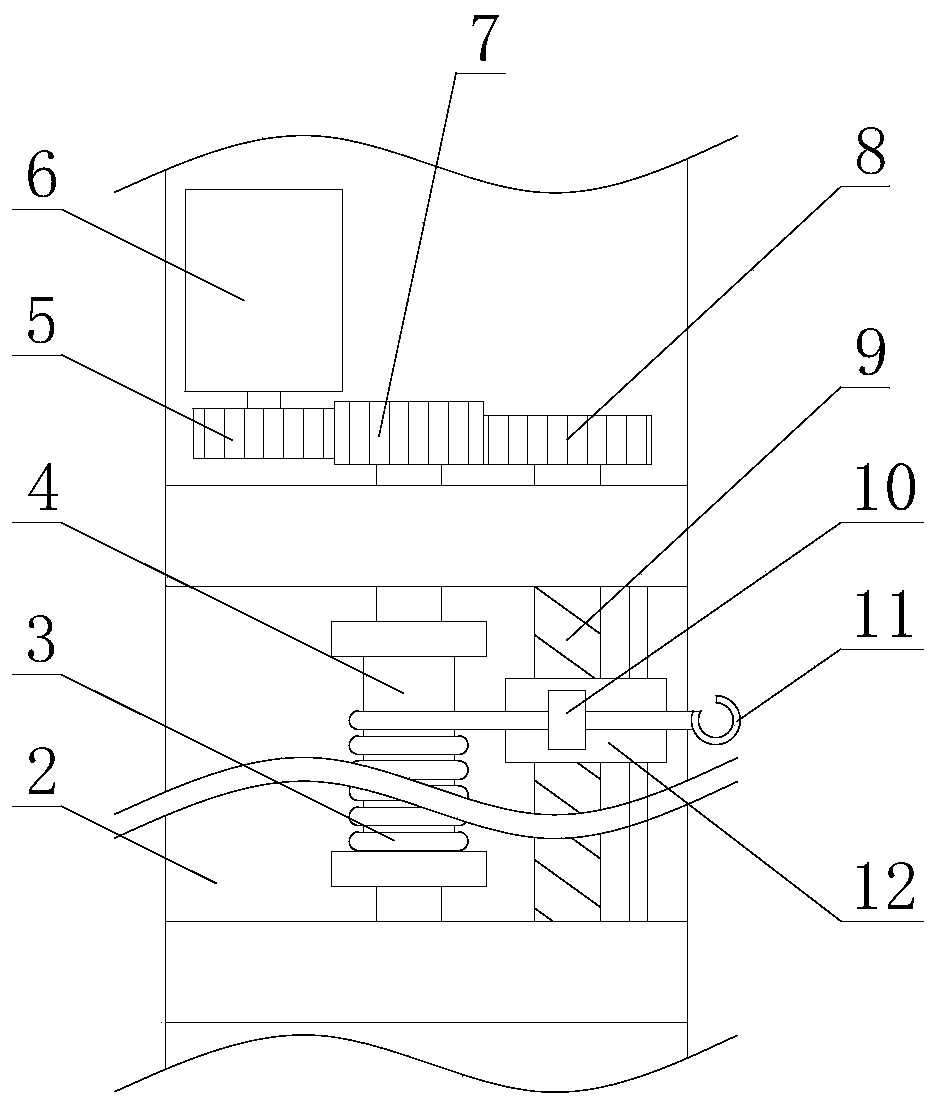

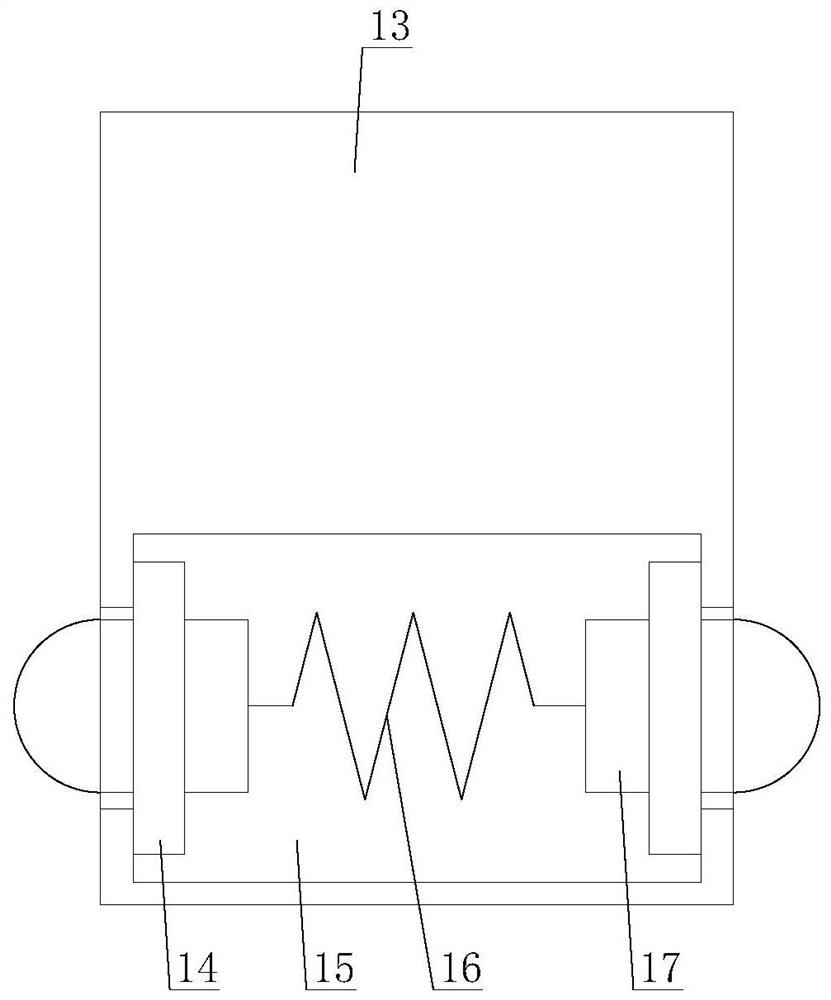

Safety lifting equipment for ship maintenance with high stability

ActiveCN110104554AImprove practicalitySimple structureTrolley cranesSafety gearMarine engineeringGantry crane

The invention relates to safety lifting equipment for ship maintenance with high stability. The equipment comprises a main beam and two brackets, and further comprises a detecting mechanism and two reinforcing mechanisms; the reinforcing mechanisms comprise driving modules, rollers, second gears, third gears, lead screws, movable blocks, guide rings, connecting wires and lifting hooks; the detecting mechanism comprises a fixed shaft, a rotating disc, a rotating shaft, a guide plate, two support rods, two trigger modules and at least two paddles; and the trigger modules comprise contact switches, slide rods, movable sleeves and springs. In the safety lifting equipment for ship maintenance with high stability, goods can be connected with the brackets through the reinforcing mechanisms, so that the shaking probability of the goods in the lifting process is reduced, and the stability of lifting the goods by a gantry crane is improved; the wind speed can be detected through the detecting mechanism; and when the wind speed reaches a set value, the operation of the gantry crane can be stopped, so that the safety of the gantry crane is improved.

Owner:日照恒远船舶工程有限公司

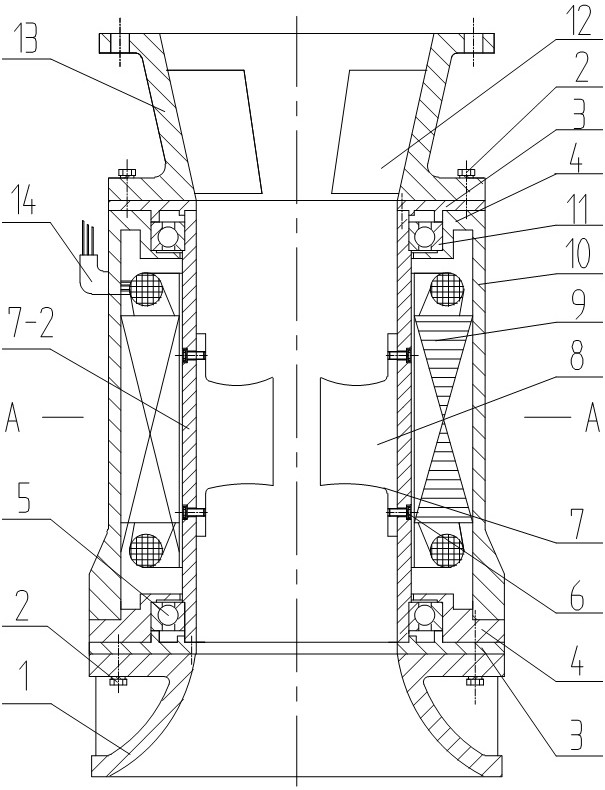

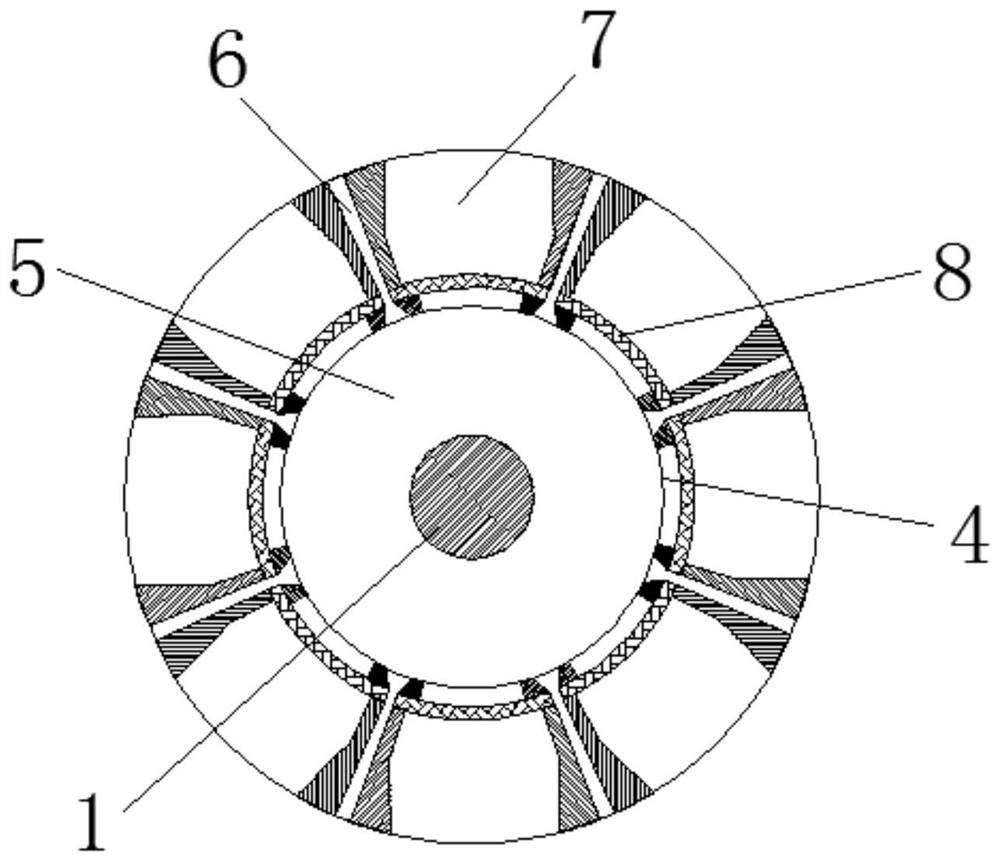

Shaftless type submersible axial flow electric pump

PendingCN111927790ALarge water flowIncrease the passing areaPump componentsPump installationsImpellerFiber

The invention discloses a shaftless type submersible axial flow electric pump and belongs to the technical field of water pumps. The shaftless type submersible axial flow electric pump comprises a water intake section, a submersible motor section and a flow deflector section; the lower end of the submersible motor section is connected with the water intake section through a fastening bolt; the flow deflector section is connected with the upper end of the submersible motor section and comprises a flow deflector and a flow deflecting blade; the flow deflector is a frustum shaped cylinder; the flow deflecting blade integrally cast with the frustum shaped cylinder of the flow deflector is arranged on the inner wall of the frustum shaped cylinder of the flow deflector; and the water intake section at the bottom of the pump is a bellmouth shaped cylinder. The shaftless type submersible axial flow electric pump has the following advantages: the shaftless type submersible axial flow electric pump shortens the overall size of the water pump, increases the passing area of the water flow passing through the cavity of the water pump, increases the water passing flow of the water pump, improvesthe hydraulic efficiency, lowers the noise during the operating process of the water pump, improves the passing capacity of sundries in water, and reduces the probability that a water pump impeller is wound with long fiber or other sundries. A magnetic fluid double suspension block bearing increases and improves the operating speed and operating stability of a motor rotor to improve the performance of the water pump.

Owner:薛峰

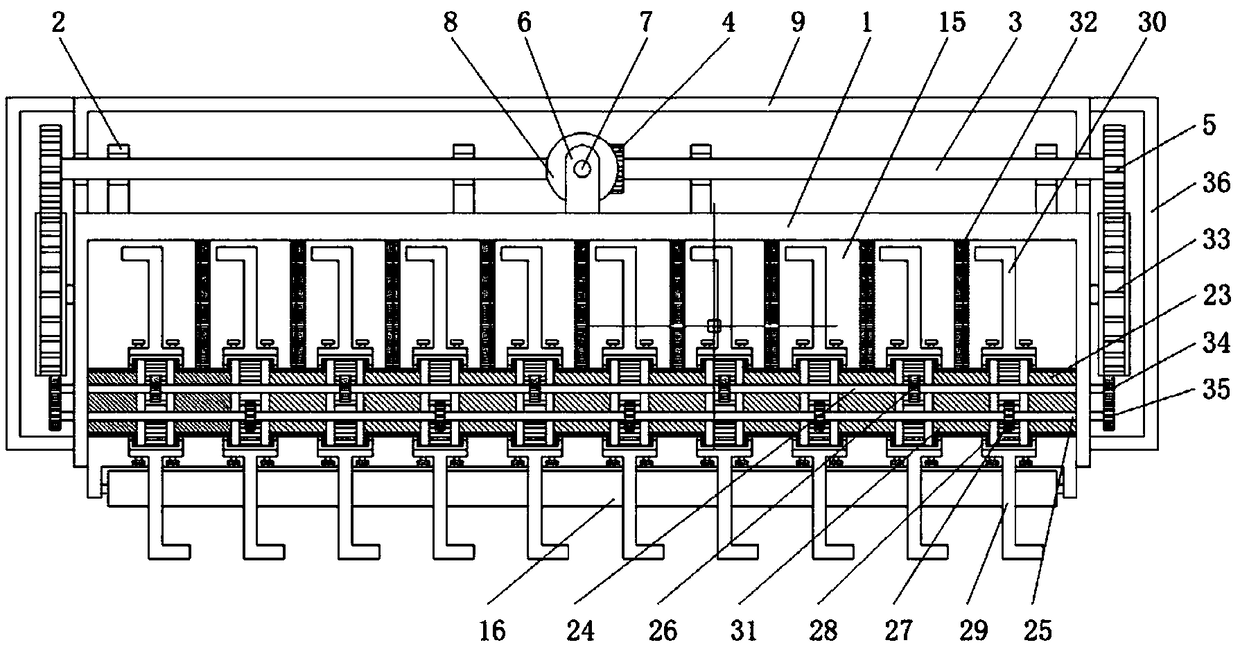

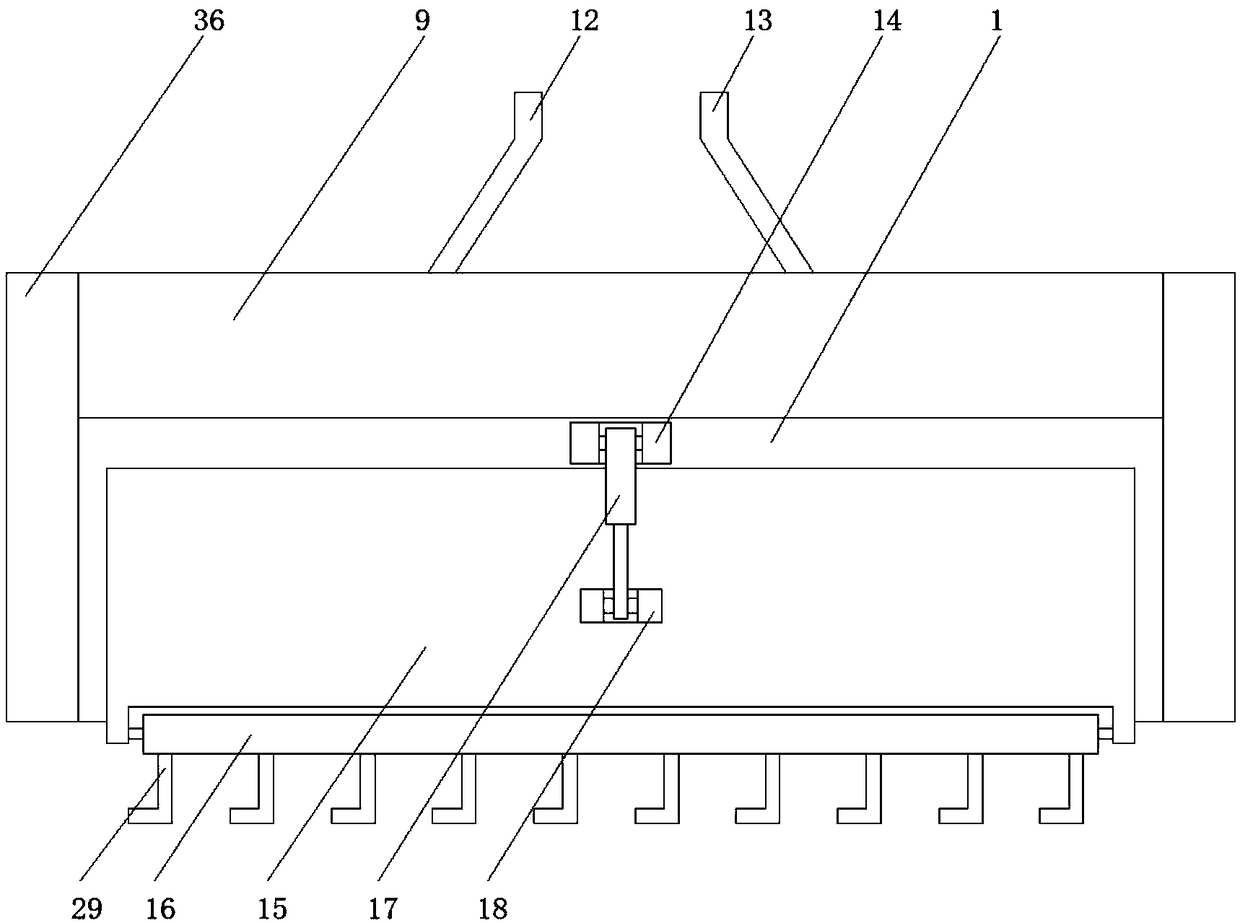

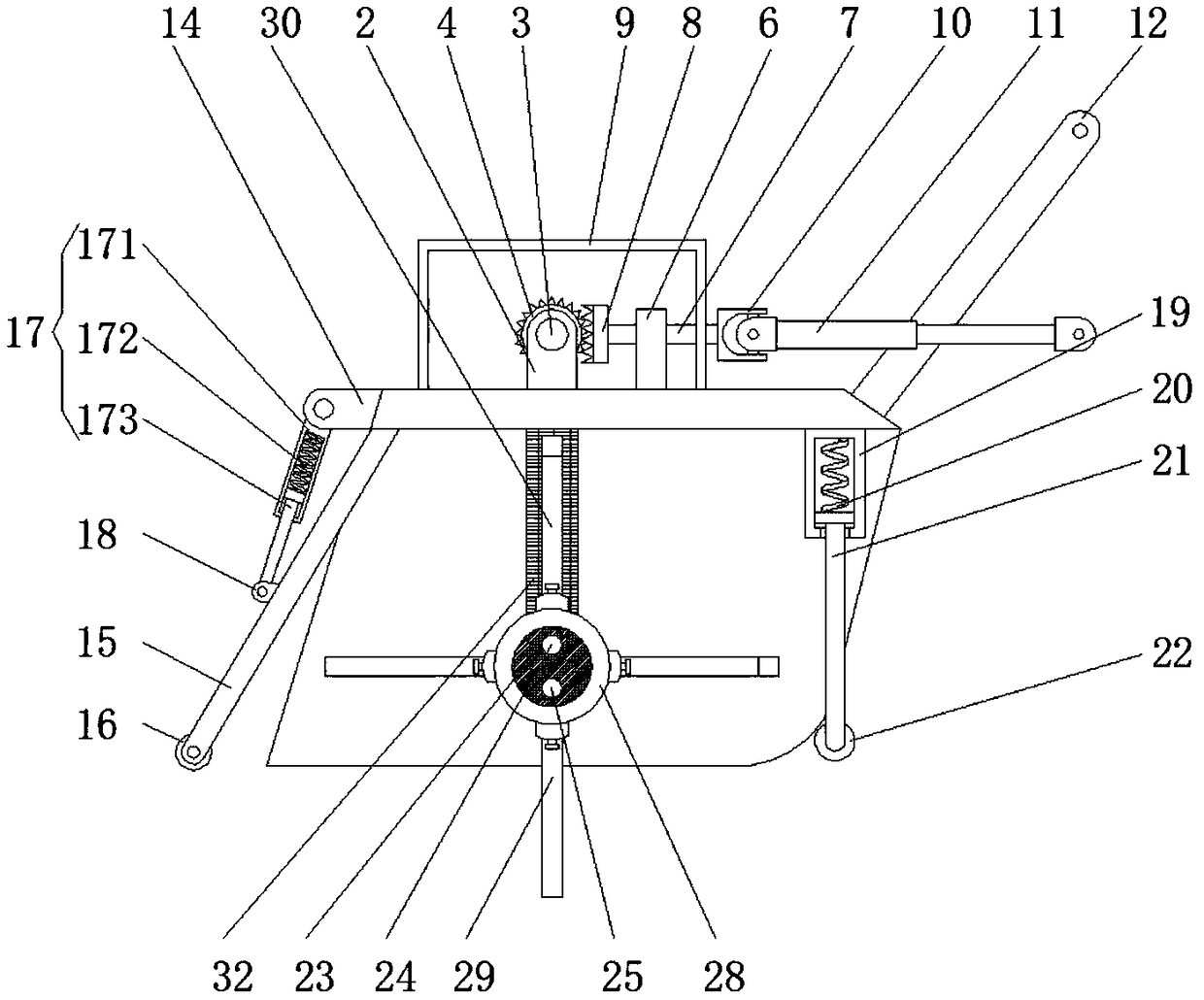

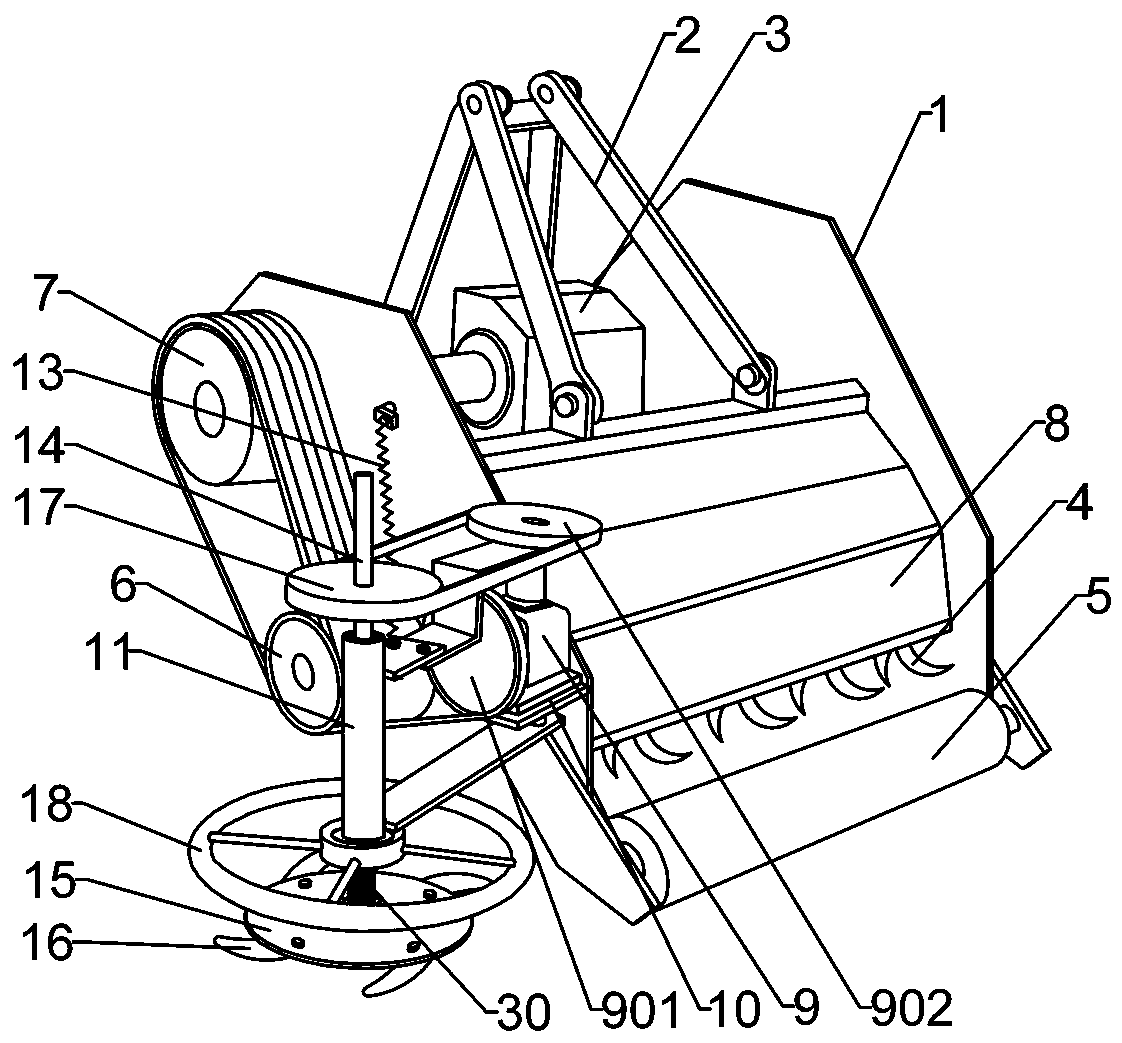

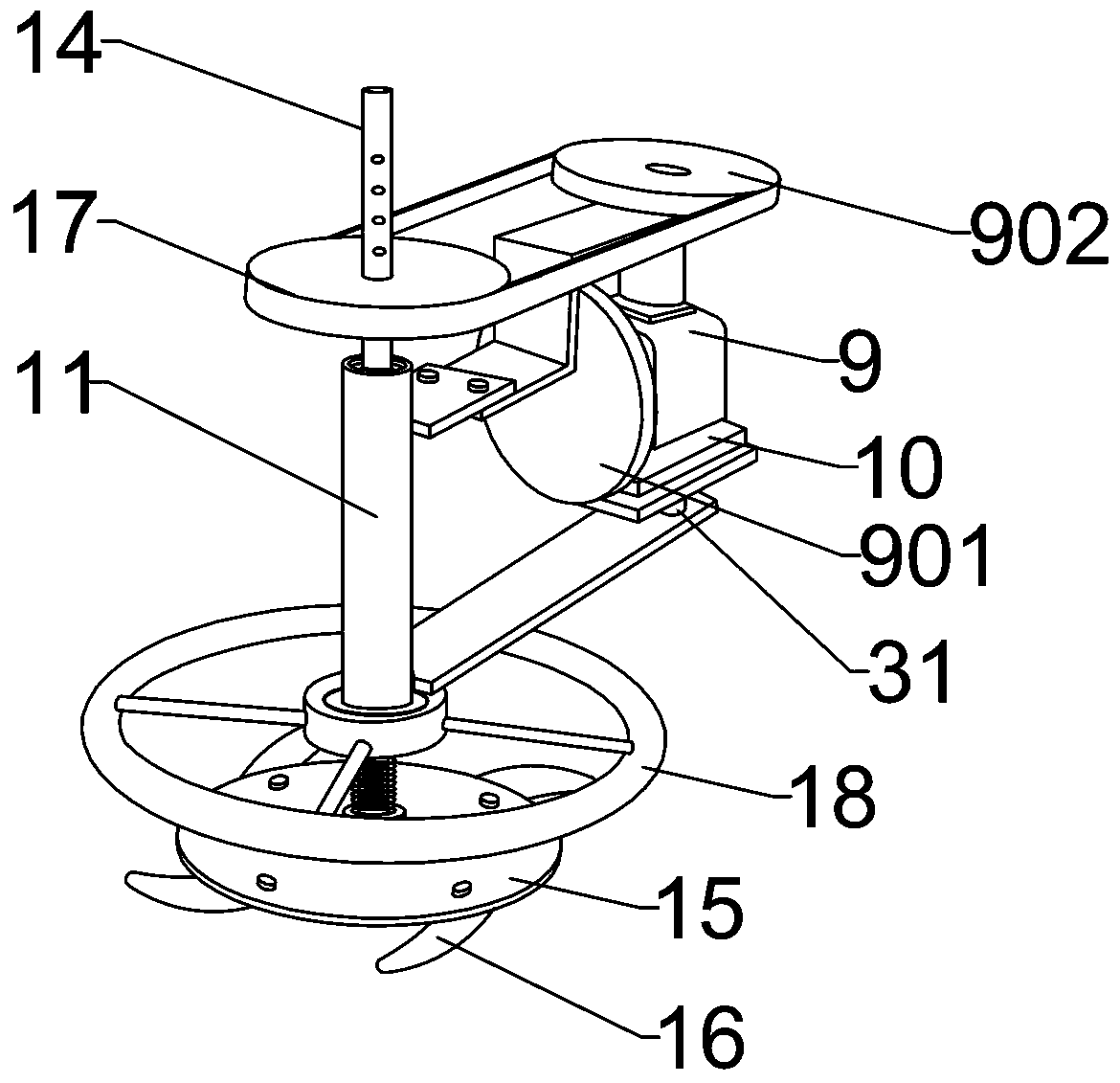

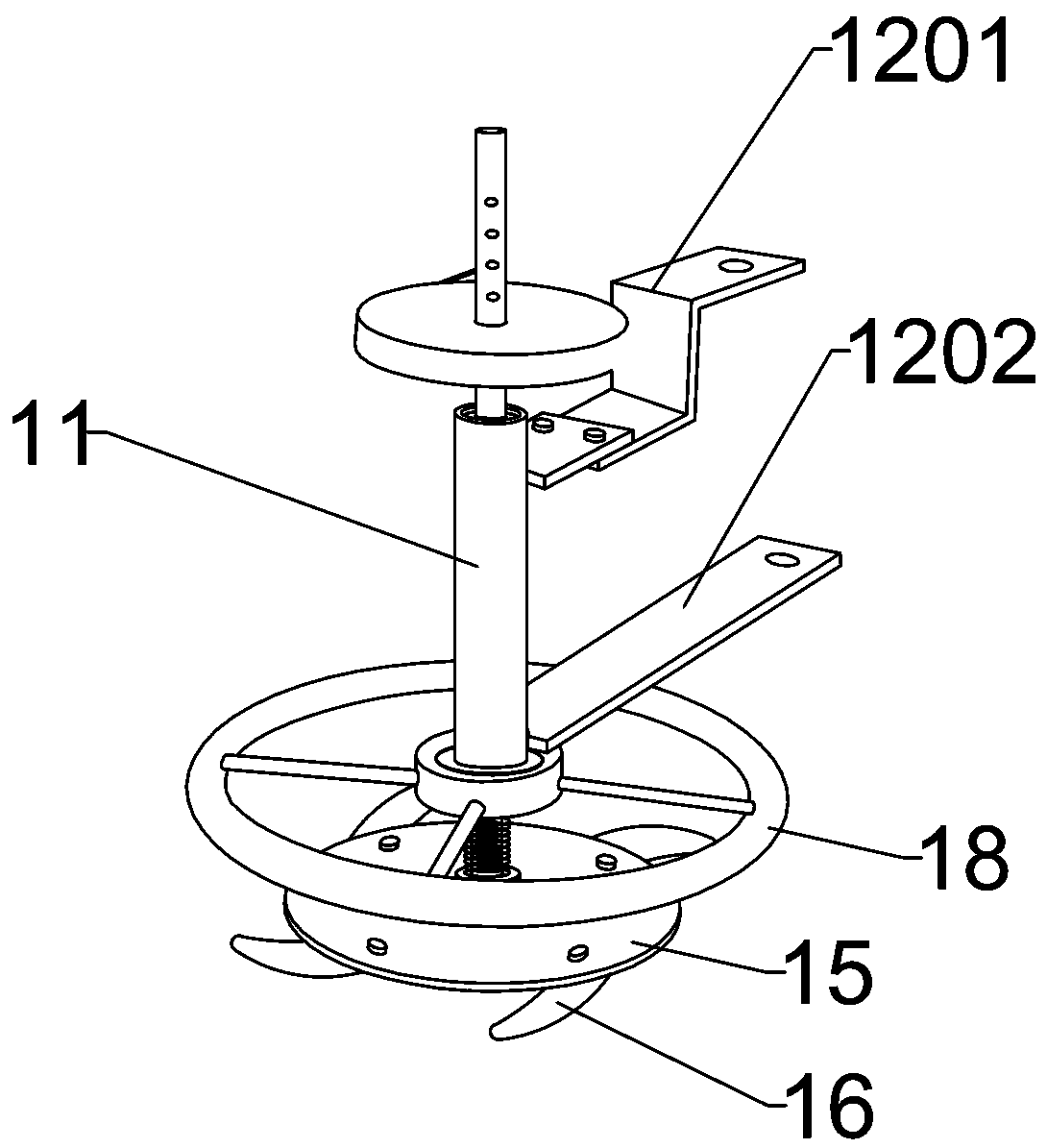

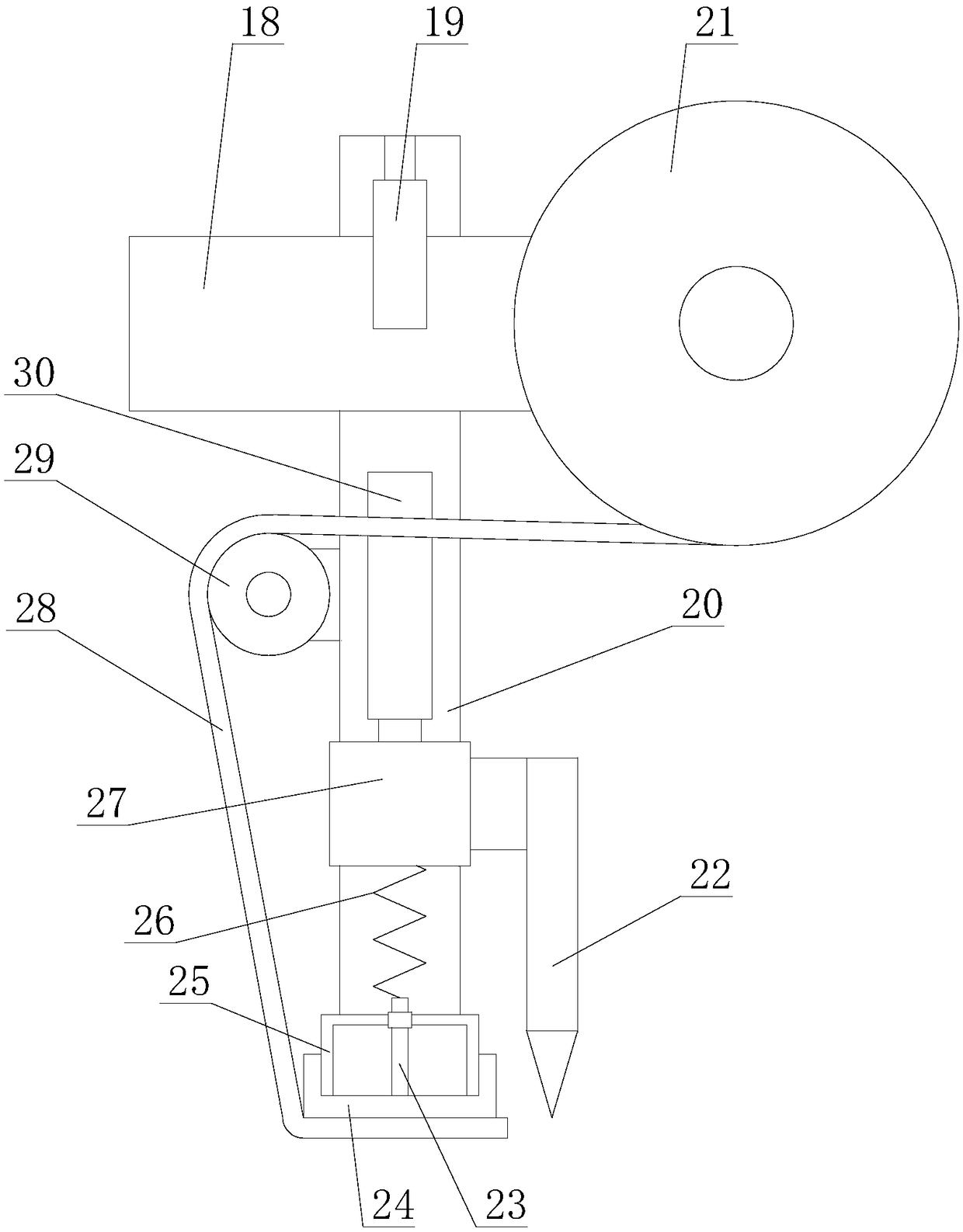

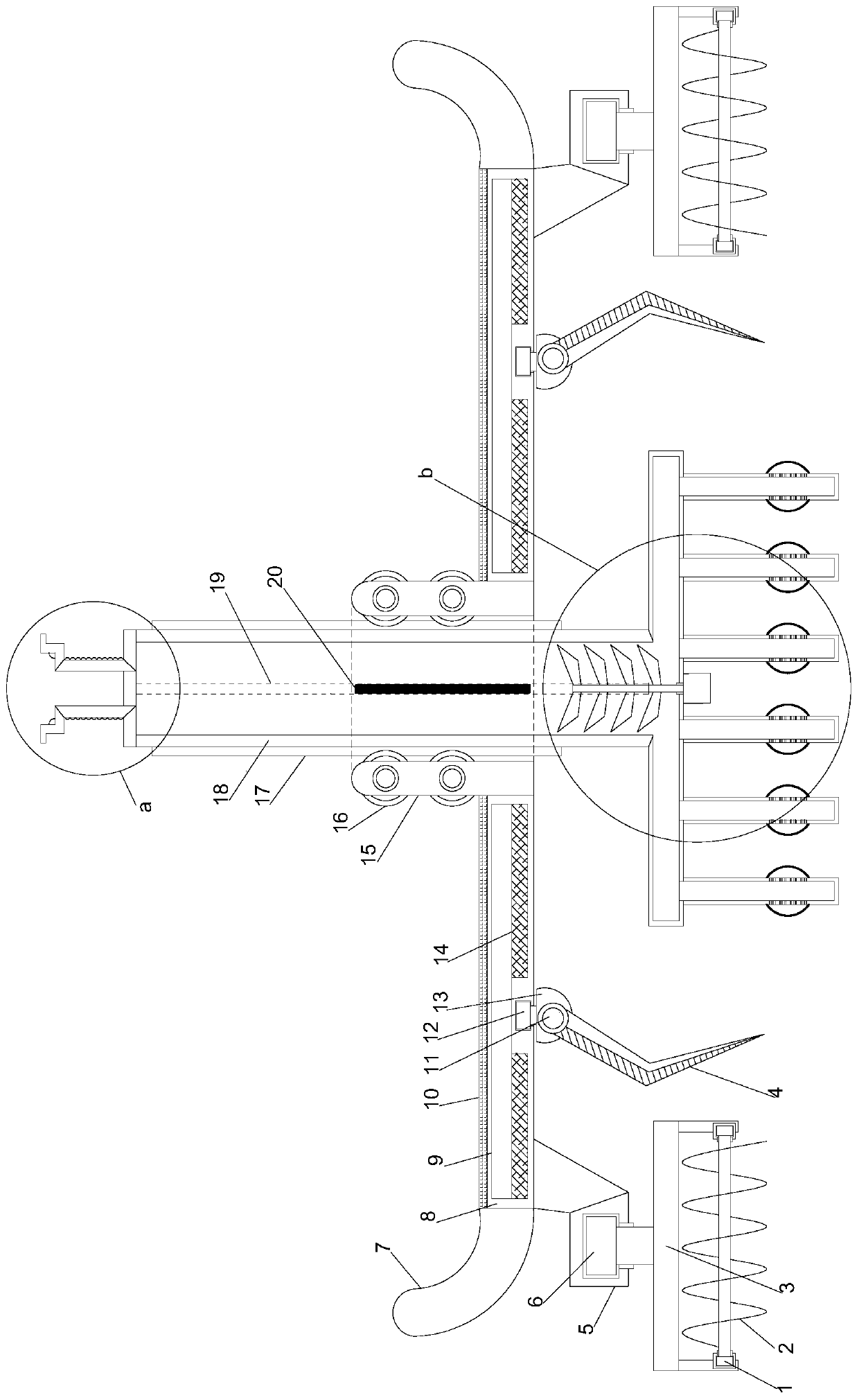

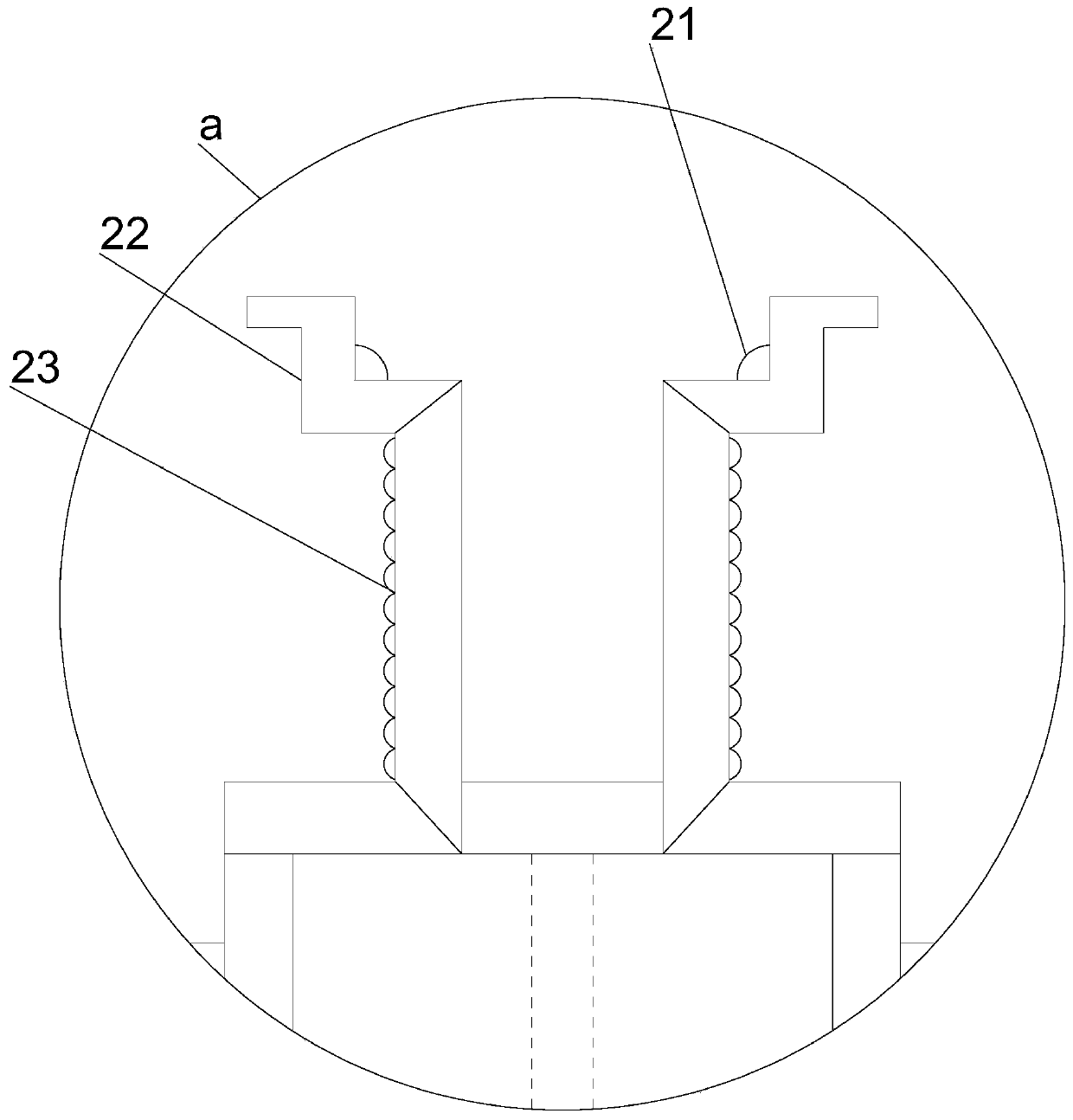

Multifunctional weeding rotary cultivator for orchard

The invention relates to the field of agricultural machinery and specifically relates to a multifunctional weeding rotary cultivator for an orchard. The multifunctional weeding rotary cultivator comprises a rack, a rotary blade shaft and rotary blades; a soil crushing grinding roller is located at the rear side of the rotary blade shaft; a double-belt belt wheel at one end of the rotary blade shaft is connected with an output belt wheel of a driving motor; a weeding mechanism comprises a steering gear and swinging arms; the steering gear is mounted on the rack and is in transmission connectionwith the double-belt belt wheel; the swinging arms are mounted at the outer side of the rack; a supporting sleeve is vertically and fixedly mounted at the tail ends of the swinging arms; the middle part of the upper swinging arm is elastically connected with the rack through a returning tension spring; the supporting sleeve movably sleeves a transmission shaft; a cutter disc and cutting blades are mounted below the transmission shaft; a transmission belt wheel in transmission connection with the steering gear sleeves the upper side of the transmission shaft; an avoiding protection ring sleeves a part, located at the upper side of the cutter disc, outside the supporting sleeve; the diameter of the avoiding protection ring is greater than the diameter of a maximum working region for rotarycutting of the cutting blades. By adopting the device, weeds at the periphery of fruit trees at two sides can be removed in a rotary cultivation process.

Owner:河南中农华盛农业科技有限公司

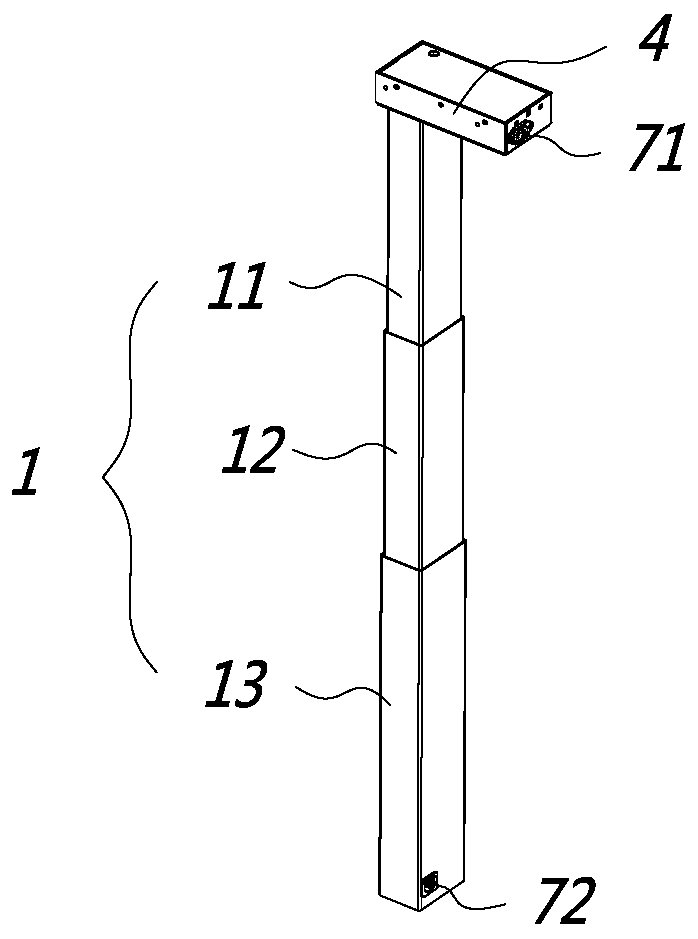

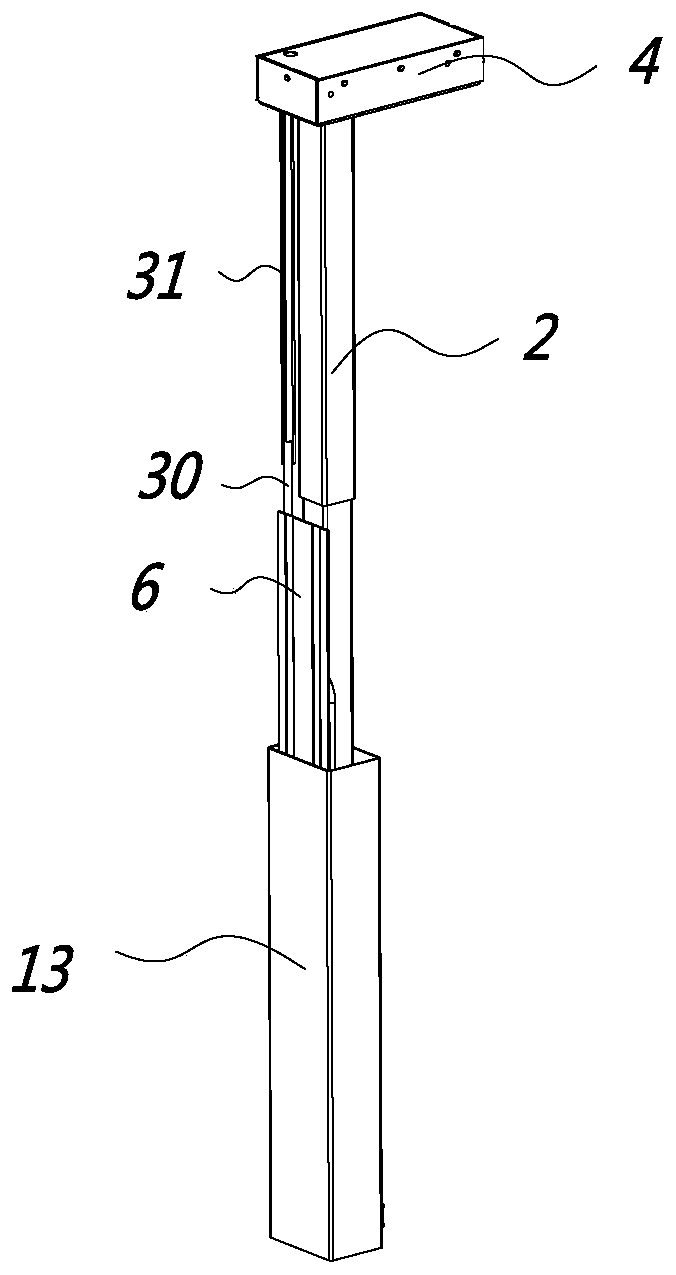

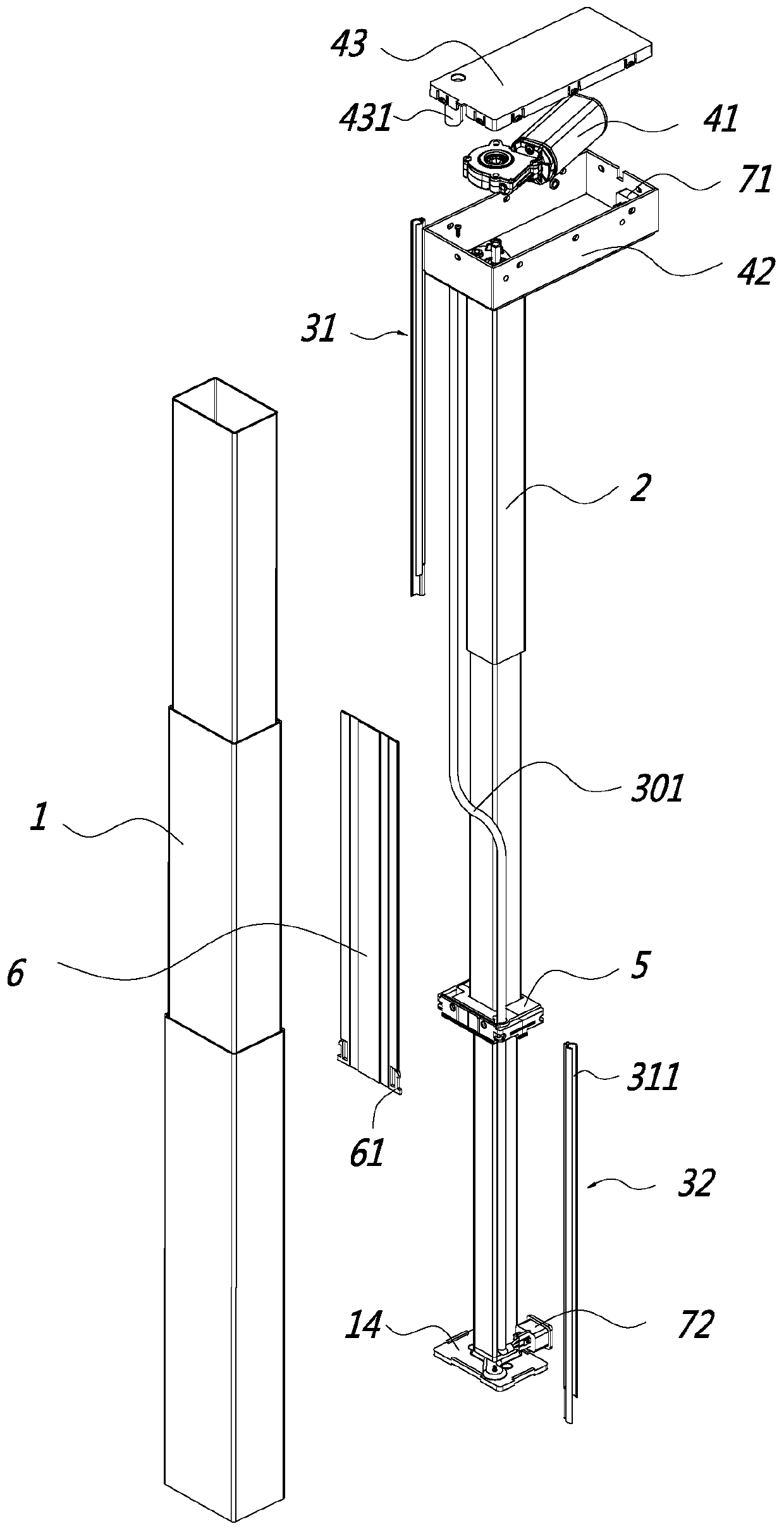

Cable built-in electric lifting stand column

The invention discloses a cable built-in electric lifting stand column, and belongs to the field of linear actuation equipment. The stand column comprises a telescopic sleeve assembly, wherein the telescopic sleeve assembly comprises at least a first sleeve and a second sleeve, a transmission assembly is arranged in the telescopic sleeve assembly, the transmission assembly drives the first sleeveand the second sleeve to stretch out and draw back relative to each other, cable clamping devices is arranged in the telescopic sleeve assembly, the cable clamping devices comprises a first cable clamping device and a second cable clamping device, the first cable clamping device is located at the upper end of the telescopic sleeve assembly, the second cable clamping device is located at the lowerend of the telescopic sleeve assembly, a cable penetrates through the interior of the telescopic sleeve assembly and is fixed by the first cable clamping device and the second cable clamping device, the upper end of the cable is fixed with the upper end of the electric lifting stand column, and the cable is pulled by the upper end of the electric lifting stand column to realize length stretching and retracting inside the telescopic sleeve assembly. The cable built-in electric lifting stand column has the advantages that some cables can be built in the electric lifting stand column, so that wiring is more tidy, and meanwhile, the safety is improved.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

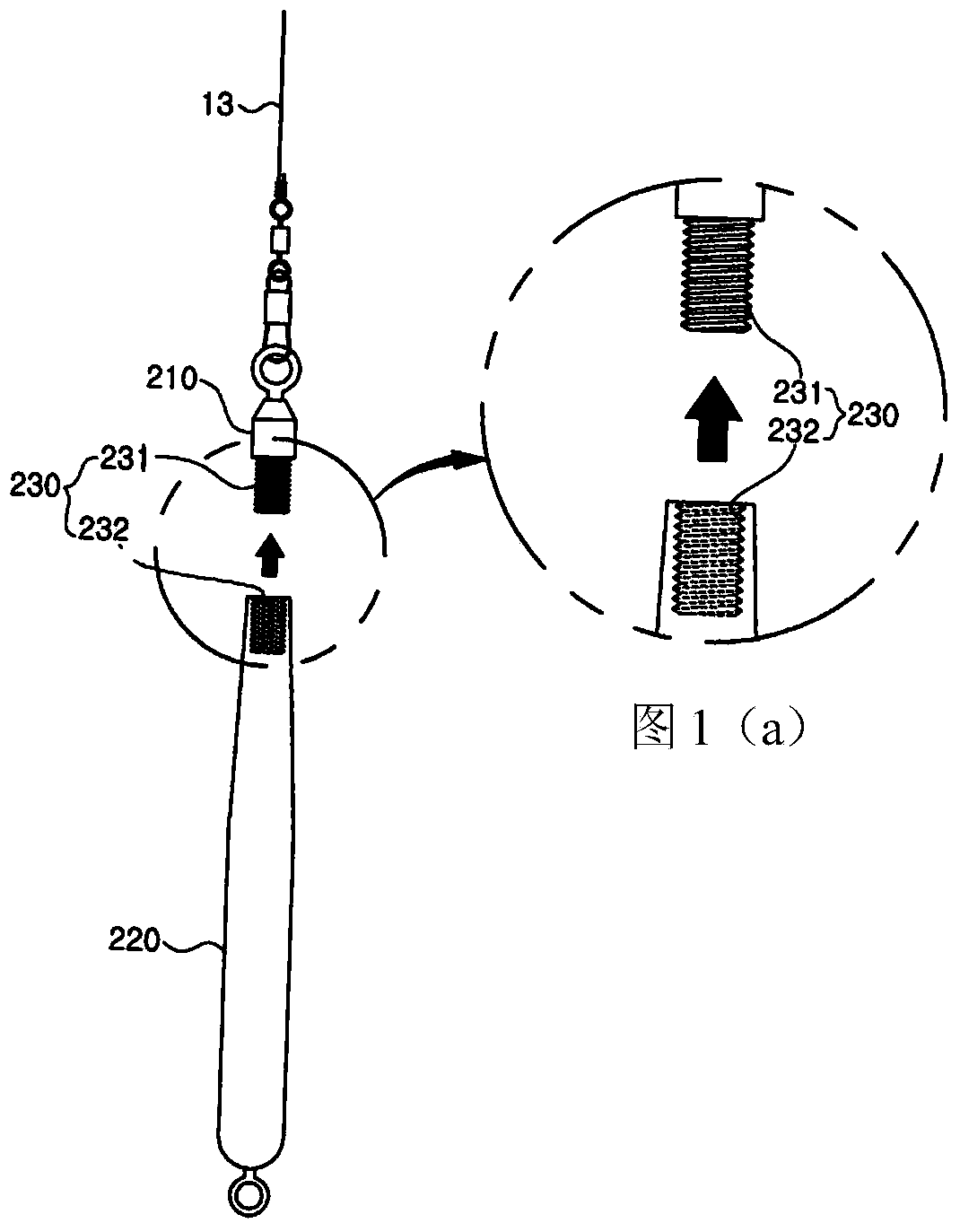

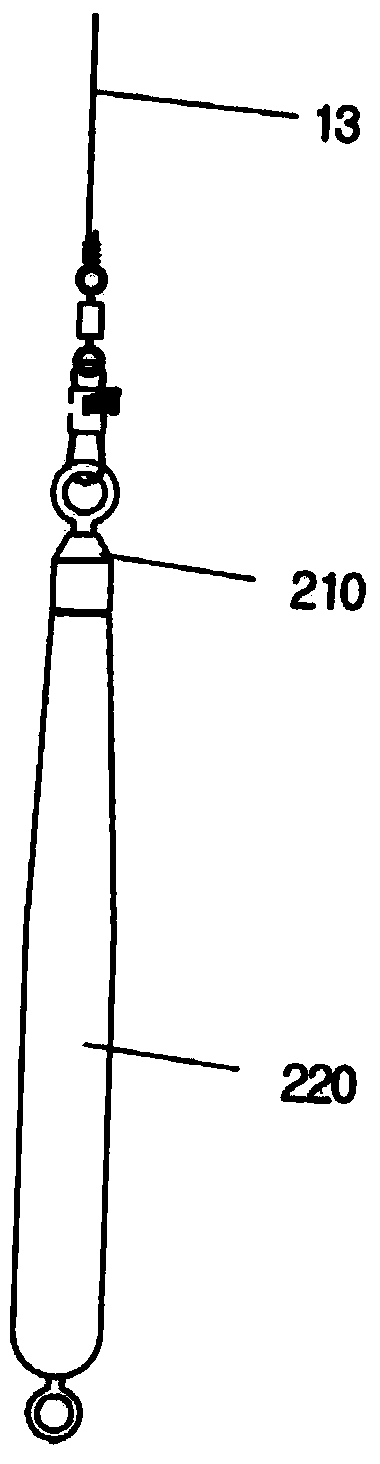

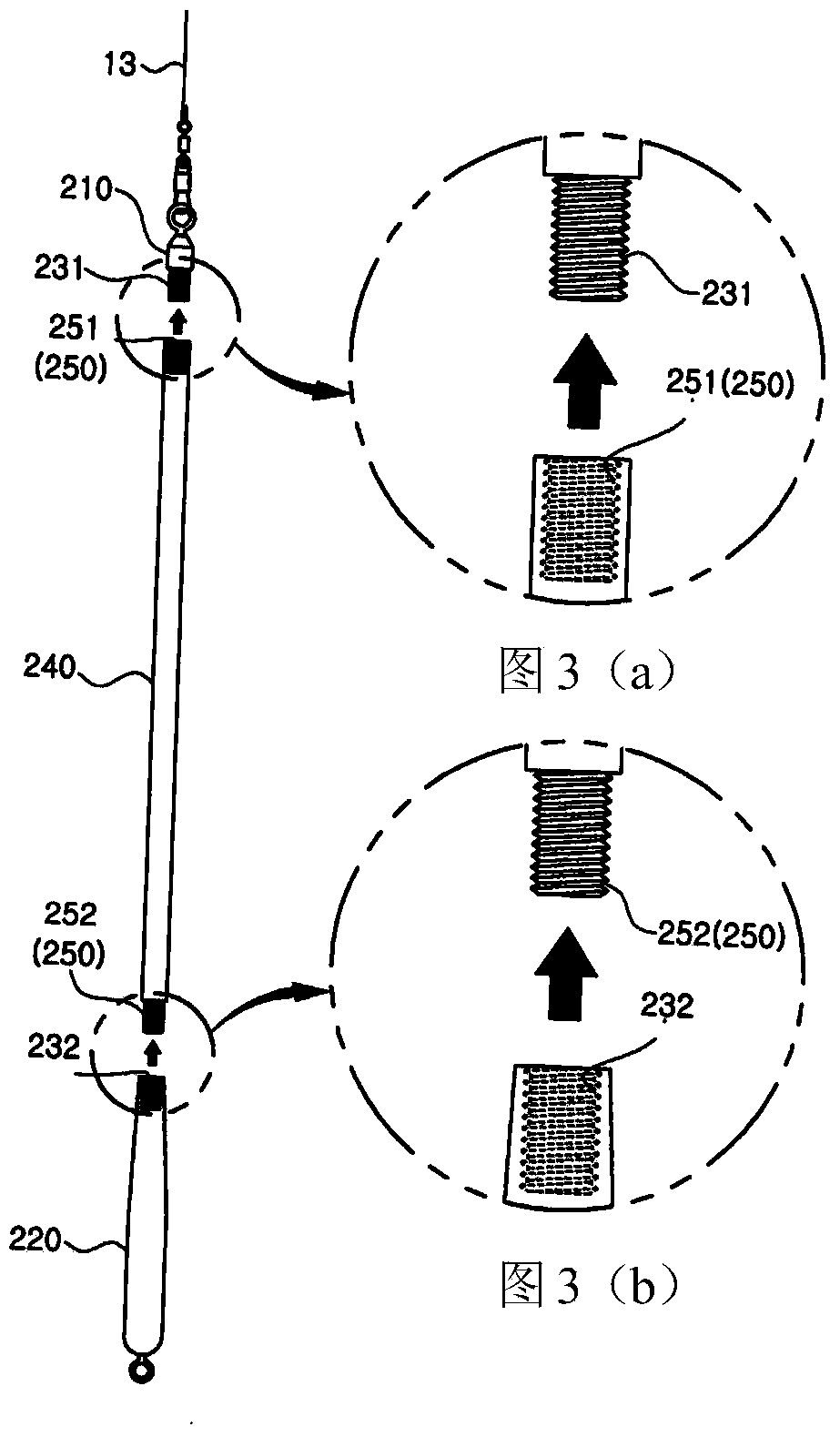

Fishing equipment

InactiveCN103891690AReduce the chance of entanglementIncrease buoyancyBaitOther angling devicesEngineeringFishing lure

The invention relates to the field of fishing, in particular to fishing equipment which consists of an artificial lure, a sinker and a float. The sinker is used for sending live bait to the bottom of the sea; the float is tied to a fishing wire and used for assisting people to judge whether fish rises to the bait and floats on water or not by naked eyes. The fishing equipment, with one end connected with a first fishing wire and the other end connected with a second fishing wire or also connected with the first fishing wire, comprises a first connection component connected with the first fishing wire, a weight component arranged on the first connection component, and a first bolt jointing unit which is jointed with the first connection component and the weight component through bolts. Further, the first bolt jointing unit comprises a first bolt unit and a first nut unit; the first bolt unit is arranged at the joint of the weight component of the first connection component, and the second nut for realizing bolt connection of the first bolt unit is disposed on the weight component. The fishing equipment has the advantages that original states of the fishing wires are kept while weight of the sinker can be adjusted.

Owner:吴世浩

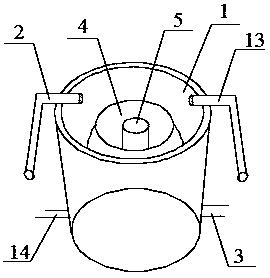

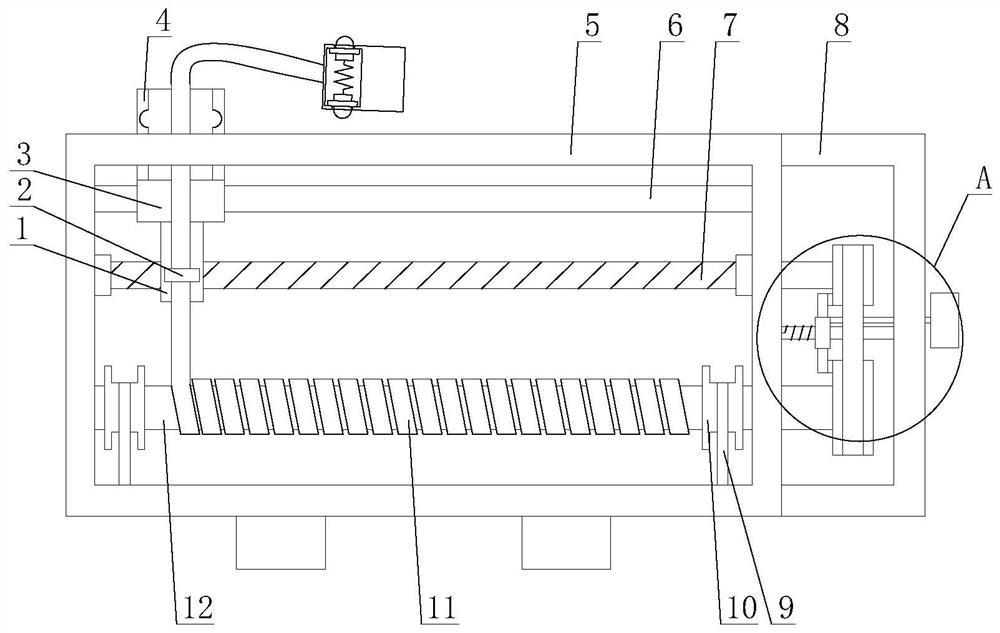

Knotting-prevention dyeing equipment for wig

InactiveCN109056248AReduce the chance of entanglementAvoid entanglementTextile treatment containersTextile treatment machine arrangementsWaste managementDyeing

The invention discloses knotting-prevention dyeing equipment for a wig. The dyeing equipment comprises a dyestuff bucket, a dyestuff inlet is formed in the top of the side wall of the dyestuff bucket,a dyestuff outlet is formed in the side wall of the bottom of the dyestuff bucket, and a knotting-prevention mechanism is arranged in the dyestuff bucket and comprises a storage cylinder used for accommodating the wig; the upper and lower ends of the storage cylinder are opened, a support pillar is arranged in the center of the storage cylinder, the side wall of the support pillar is connected with the side wall of the dyestuff bucket through several uniformly-distributed connecting rods, and the connecting rods divide the outlet end of the bottom of the dyestuff bucket into several wig storage areas; annular slide grooves are circumferentially formed in the side wall of the dyestuff bucket connected with the connecting rods, all the connecting rods are slidably connected with the annularslide grooves through slide blocks, a storage box is arranged at the bottom of the dyestuff bucket, a rotary motor is arranged at the portion, corresponding to the support pillar, in the storage box,and a rotary shaft of the rotary motor penetrates through the top of the storage cylinder to be connected with the bottom of the support pillar. By means of the dyeing equipment, the wig is more uniformly dyed; meanwhile, the wig is prevented from being knotted in the dyeing process.

Owner:朱文统

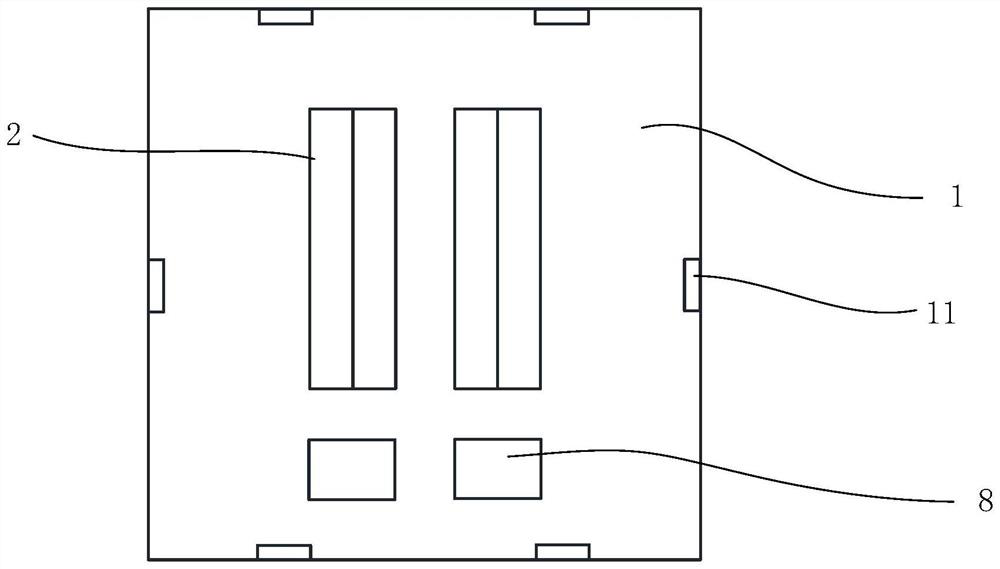

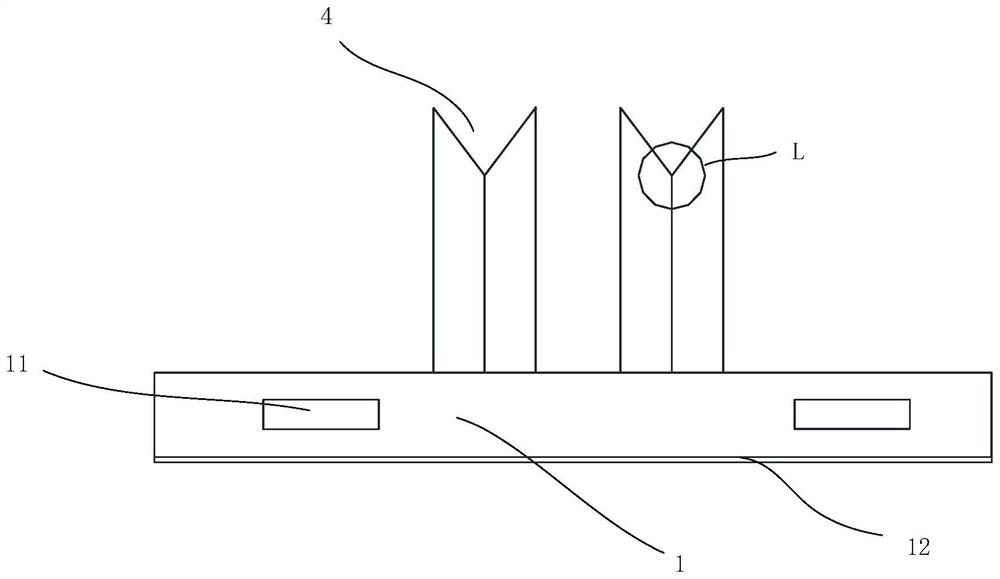

Intelligent manufacturing device for knitted clothing

ActiveCN109355818AEasy to installEasy to disassembleWork-collecting devicesThread-laying mechanismsPlastic packagingControl engineering

The invention discloses an intelligent manufacturing device for knitted clothing. The intelligent manufacturing device comprises an intelligent manufacturing device body, an installation stand is fixedly installed on the outer surface in the middle at the upper end of the intelligent manufacturing device body, a transverse shaft is fixedly installed on the outer surface in the middle at the frontend of the installation stand, a machine box is fixedly installed on the outer surface at the front end of the transverse shaft, and the transverse shaft is fixedly connected to the outer surface at the upper end of the machine box. A thread separating mechanism is fixedly connected to the outer surface on one side of the installation stand, and a fixing plate is fixedly installed on the outer surface at the lower end of the intelligent manufacturing device body. Through an installation and disassembly mechanism, needles on the machine can be installed and disassembled, and it is convenient for people to use the device; through the thread separating mechanism, connecting threads can be separated and isolated, the connecting threads are prevented from being twined in the machine, the woundthread can be disposed in time, and more convenience is brought to use of people; through a plastic packaging mechanism, the manufactured clothing can be packaged, the situation that the clothing is placed at random, and consequently, the clothing is damaged is prevented, and using of people is facilitated.

Owner:嘉兴羽希服饰有限公司

Autoclaved aerated concrete cut block and process thereof

The invention discloses an autoclaved aerated concrete cut block. The autoclaved aerated concrete cut block is composed of the following components in parts by weight: 25 to 35 parts of cement, 5 to 15 parts of gypsum, 4 to 7 parts of aluminum powder, 5 to 10 parts of glycol, 30 to 40 parts of fly ash, 15 to 25 parts of alkali-resistant glass fiber, 3 to 5 parts of a water reducing agent, 50 to 70parts of water and 6 to 10 parts of an additive. The process comprises the following steps: S1, liquid mixing; S2, stirring; S3, mixing; S4, foaming; S5, pouring; S6, shaping; S7, cutting; and S8, autoclaving. According to the invention, through addition of the alkali-resistant glass fiber and the fly ash, uniform mixing of the alkali-resistant glass fiber is promoted; the glycol can also exert the effect of uniform dispersion; meanwhile, the alkali-resistant glass fiber is easy to wind into a cluster during mixing; thus, the alkali-resistant glass fiber is slowly added under stirring in thestep S3, so the probability of the alkali-resistant glass fiber winding into a cluster is reduced, and facilitation of uniform mixing is realized at the same time.

Owner:JIANGSU CHENGGONG CONSTR TECH

Small sample dyeing bracket for filament/yarn laboratory

InactiveCN105755721AReduce wearReduce frictionTextile treatment dyeing devicesTextile treatment carriersYarnFiber

The invention discloses a small sample dyeing bracket for a filament / yarn laboratory.The small sample dyeing bracket comprises a supporting assembly.The supporting assembly comprises one or more supporting stand columns, a first supporting plate and a second supporting plate, wherein the interval between the first supporting plate and the second supporting plate is fixed or adjustable, the supporting stand columns are connected to the first supporting plate and the second supporting plate, the periphery of the outer side of the first supporting plate is provided with a plurality of first wrapping posts, and the periphery of the outer side of the second supporting plate is provided with a plurality of second wrapping posts.The small sample dyeing bracket has the advantages that the structure is simple, operation is simple and convenient, and winding thickness of filament or yarn can be reduced, so that the situation that filament or yarn covers each other is reduced to the maximum degree, dye liquor can evenly and effectively penetrate all parts of fibers, the even dyeing effect is achieved, and the chance of mutual winding of filament or yarn is reduced.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE +1

Portable waterproof socket

ActiveCN113381233AEasy to rollReduce the chance of entanglementCouplings bases/casesFlexible lead accommodationStructural engineeringStormwater

The invention relates to a portable waterproof socket which comprises a socket body, a main power line used for supplying power to the socket body is arranged on the socket body, jacks are formed in the side faces of the two sides of the socket body in the width direction, the socket body is provided with two rain shielding pieces, and the two rain shielding pieces are located on the two sides of the socket body in the width direction respectively. The rain shielding piece comprises a first plate and two second plates, the two ends of the first plate are arranged on the two second plates respectively, the first plate and the two second plates are all arranged on the side face of one side of the socket body in the width direction, the first plate is located above the jacks, and the jacks are jointly surrounded by the first plate and the two second plates. The first plate can shield a part of rainwater hit on the socket body from the upper side, the falling direction of the rainwater can be changed when the rainwater is blown by wind, and the two second plates can shield the rainwater hit from the two sides of the socket body, so that the probability that the rainwater flows to the jacks is reduced, and the outdoor use of the socket is safer.

Owner:台州菲尼科斯电气科技有限公司

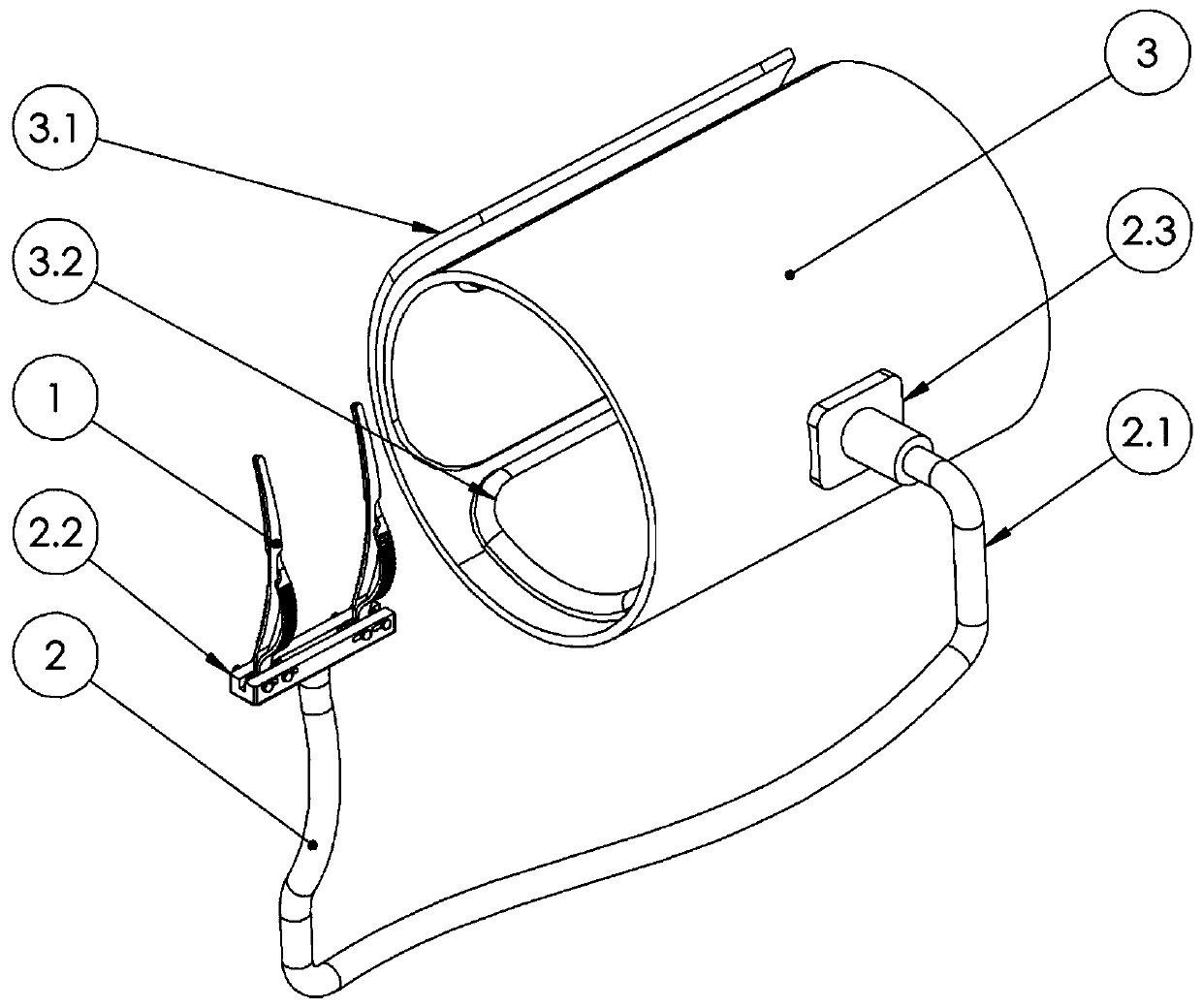

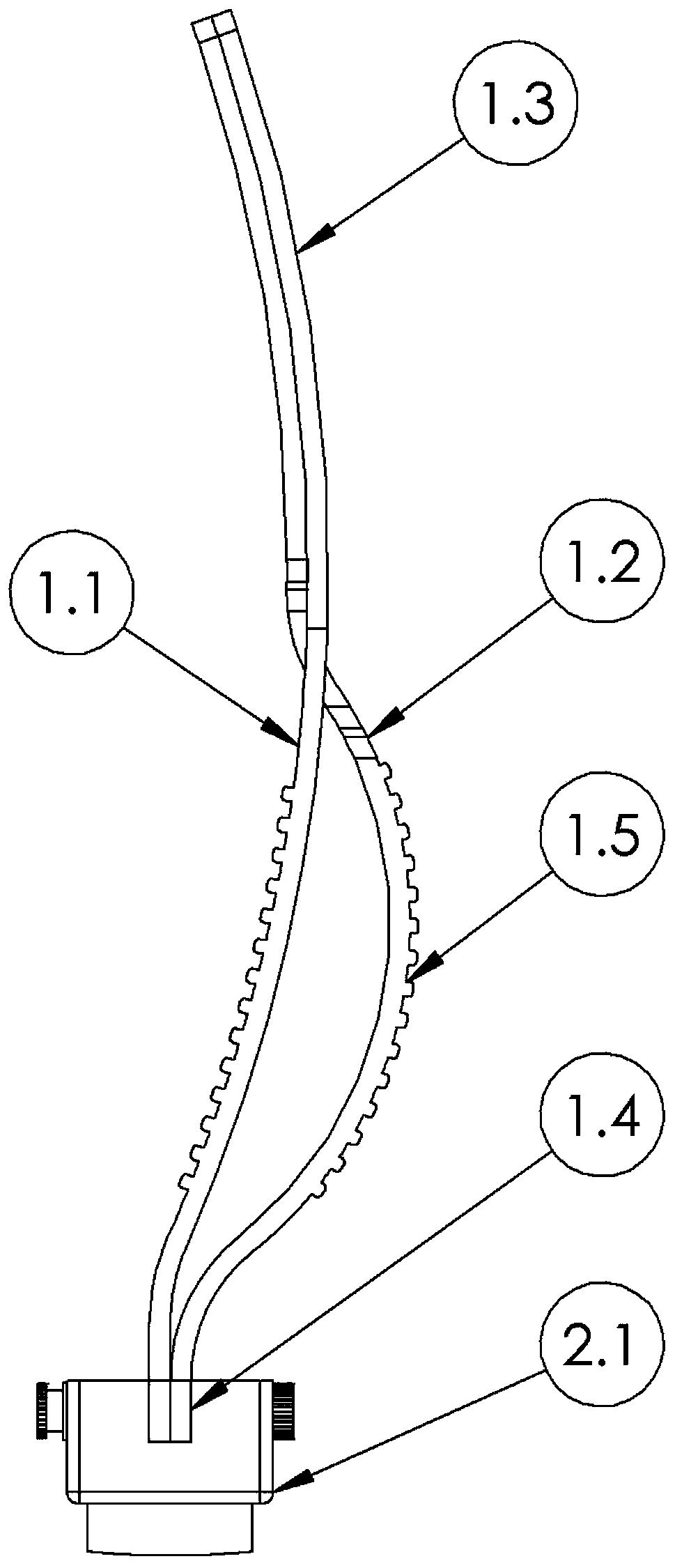

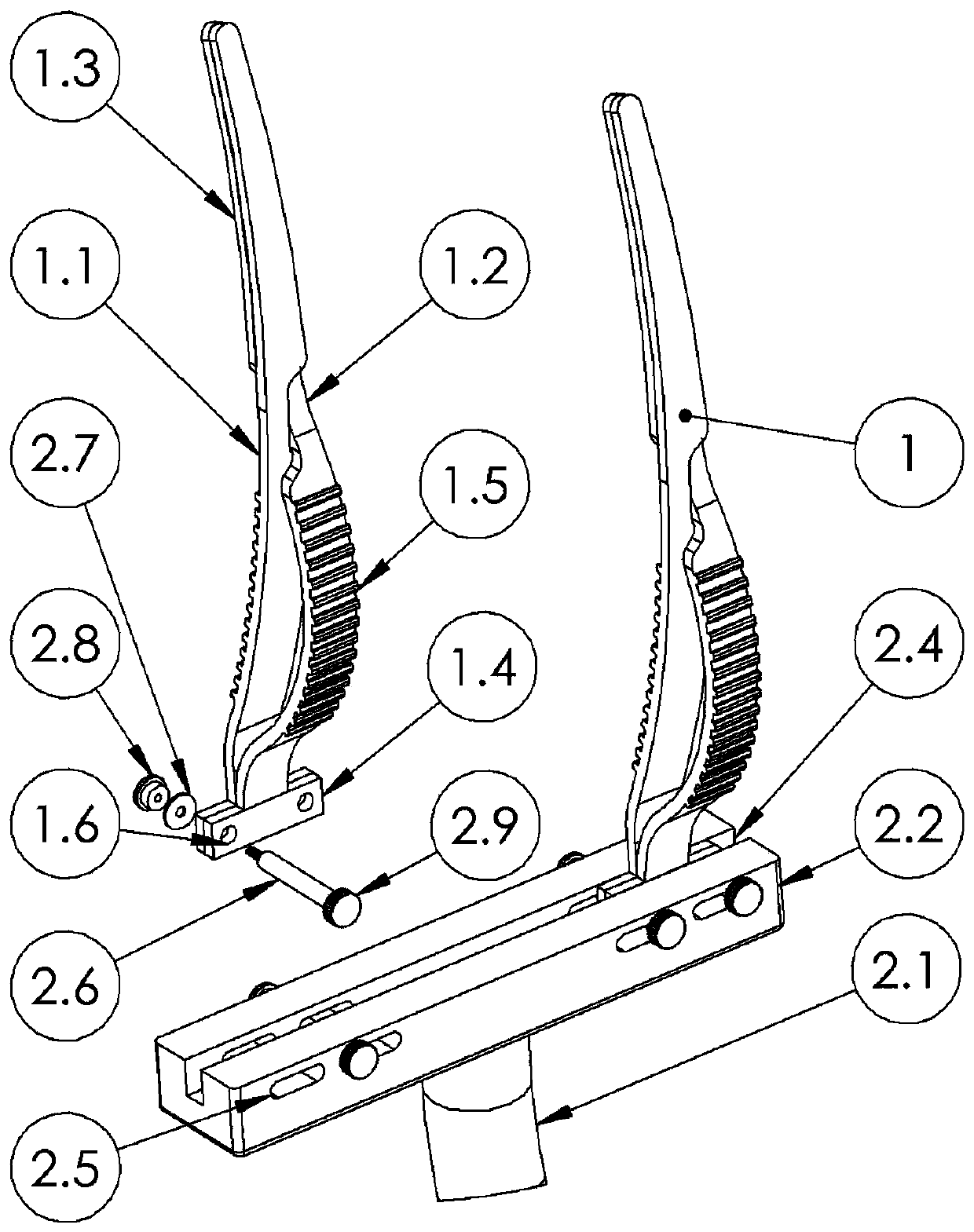

Wearable arm vascular clamp and using method thereof

PendingCN110338872AReduce the chance of entanglementLarge operating spaceWound clampsEngineeringBlood vessel

The invention provides a wearable arm vascular clamp and a using method thereof. The wearable arm vascular clamp comprises two arc-shaped vascular clamp bodies consistent in specification, a flexiblerod and an arm fixing belt; the arc-shaped vascular clamp bodies are detachably connected to one end of the flexible rod, and the arm fixing belt is fixedly connected to the other end of the flexiblerod. The wearable arm vascular clamp is simple in structure and convenient to use, the probability that an operator touches the tail part of the vascular clamp can be reduced, and the probability thatthe tail part of the vascular clamp and a suture line are twisted is reduced. The tail part of the vascular clamp is fixed, so that the clamping plane of the vascular clamp is not easy to shift; meanwhile, the design of the flexible rod makes the vascular clamp have an adjusting function and suitable for different patients.

Owner:陈彬

New energy resource automobile air conditioning system facilitating filter element replacement

ActiveCN108725131AImprove practicalityImprove replacement efficiencyAir-treating devicesVehicle heating/cooling devicesNew energyAutomobile air conditioning

The invention relates to a new energy resource automobile air conditioning system facilitating filter element replacement. The new energy resource automobile air conditioning system facilitating filter element replacement comprises a main body, a filter element, a replacement opening and two ventilation openings and also comprises a putaway mechanism and two packaging mechanisms, wherein the putaway mechanism comprises a guiding rod, a driving assembly, a sliding block, a supporting assembly, a fixing rod, a fixing sleeve, a power plate, a connecting rod, movable wheels, a first spring and a friction block, and each packaging mechanism comprises a supporting plate, a lifting rod, a first air cylinder, a second air cylinder, a material receiving cylinder, adhesive tapes, an adsorption assembly, a lifting sleeve, a blade and a second spring. According to the new energy resource automobile air conditioning system facilitating filter element replacement, the filter element can be automatically moved out of the main body through the putaway mechanism and meanwhile can be also moved into the main body, accordingly the filter element replacement efficiency of the air conditioning system is improved, the adhesive tapes can be adhered to two sides of the filter element, accordingly the probability can be reduced that dust on the filter element falls into an automobile, and the inside ofthe new energy resource automobile can be kept clean.

Owner:苏州市相城区黄桥工业园经济发展有限公司

Preparation method of nitrogen-doped carbon nanotube compositing TiO2 composite material

InactiveCN109529901ABreak through chemical inertnessFully contactedPhysical/chemical process catalystsAmmoniaUltraviolet irradiation

The invention provides a preparation method of a nitrogen-doped carbon nanotube compositing TiO2 composite material. The method includes: pretreating a carbon nanotube material at first; then performing a reaction with the carbon nanotube and ammonia water to prepare a nitrogen-doped carbon nanotube material; finally adding TiO2 to direct prepare the nitrogen-doped carbon nanotube compositing TiO2composite material, which can effectively solve the problem that carbon nanotubes are quite liable to aggregate. Not only that, by compounding the TiO2 with the nitrogen-doped carbon nanotubes, the product can overcome the problem that TiO2, during use, is difficult to separate and recycle; meanwhile, under ultraviolet irradiation, more excellent catalytic degradation effect is achieved.

Owner:DONGGUAN UNIV OF TECH

Communication base station with water leakage prevention function

InactiveCN108412253AWith anti-leakage functionReduce the chance of water leaksBuilding repairsBuilding insulationsWater leakageWater flow

The invention relates to a communication base station with a water leakage prevention function. The communication base station comprises a body, a base, a waterproofing mechanism and a repairing mechanism, wherein the repairing mechanism comprises a guiding rod, a second moving assembly, a nozzle, a material delivery pipe, a high-pressure pump, a material storage box, two guiding rails and two first moving assemblies, and the repairing mechanism further comprises a driving assembly, a rotary shaft, a first gear, two first transmission rods, two reinforcing sleeve tubes and two transmission assemblies. According to the communication base station with the water leakage prevention function, the nozzle can be driven to move on the station through the repairing mechanism, asphalt is sprayed onthe station through the nozzle, so that the repairing of cracks on the top of the communication base station is achieved, the possibility of water leakage occurrence of the communication base stationis reduced and the practicability of the communication base station is improved, through the repairing mechanism, the communication base station can be driven to lift up and lower down, so that the possibility that accumulated water flows into the communication base station is reduced, and the practicability of the communication base station is further improved.

Owner:黄娉

Practical industrial endoscope

InactiveCN108490602AReduce the chance of entanglementImprove practicalityCleaning using toolsTelescopesDrive wheelTransmission belt

The invention relates to a practical industrial endoscope. The practical industrial endoscope comprises a main body, a cable, a photographing mechanism and a wire collection mechanism, wherein the wire collection mechanism comprises a first driving assembly, a cleaning assembly, a first rotating shaft, a wire reel and a first gear; the cleaning assembly comprises a reinforcing lantern ring, a rotating sleeve, a cleaning brush, an annular gear and a cleaning ring; the photographing mechanism comprises a second driving assembly, a shell, a second rotating shaft, a rotating block, a camera, a driven wheel and two reinforcing plates; the first driving assembly comprises a first motor and a second gear; and the second driving component comprises a second motor, a driving wheel and a transmission belt. According to the practical industrial endoscope, cables can be orderly stored in the main body by virtue of the wire collection mechanism, so that the winding probability of the cables is decreased, and the practicability of the industrial endoscope is improved; and the angle adjustment of the camera is realized by virtue of the photographing mechanism, so that the photographing range of the practical industrial endoscope is enlarged.

Owner:南安市威速电子科技有限公司

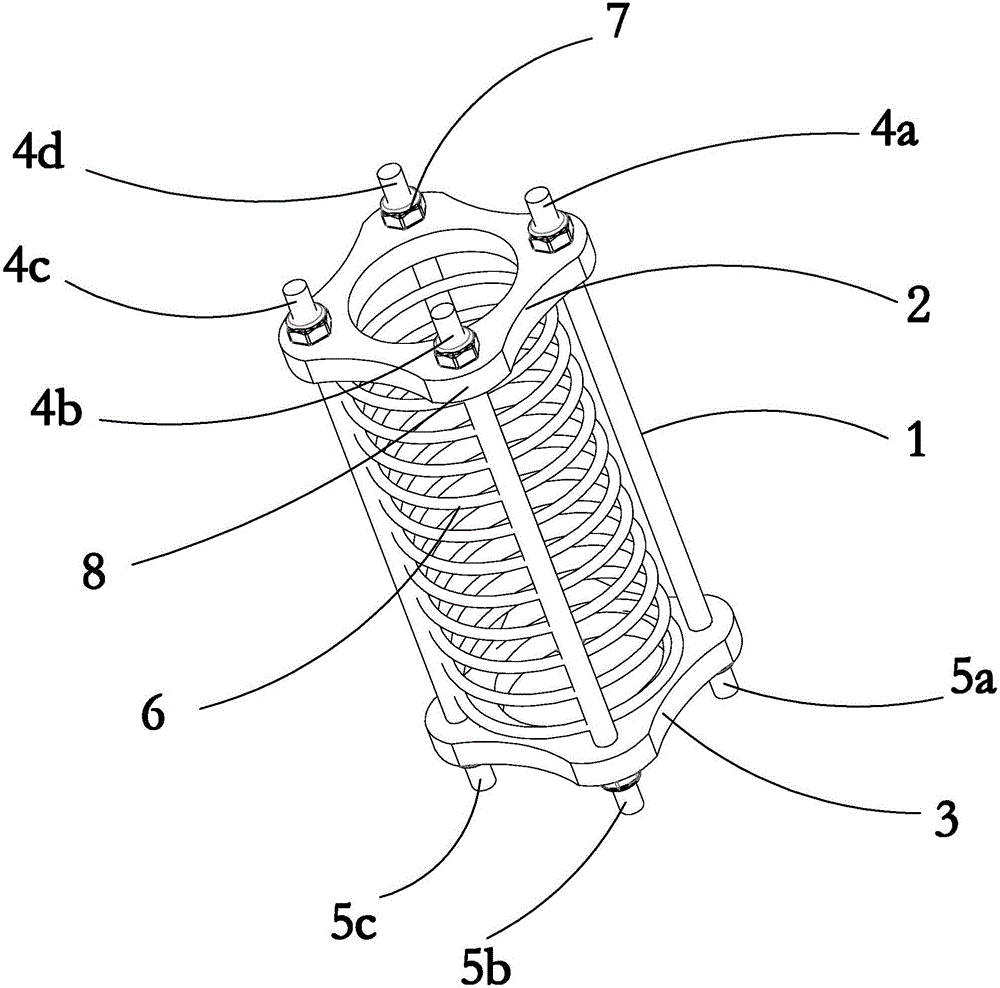

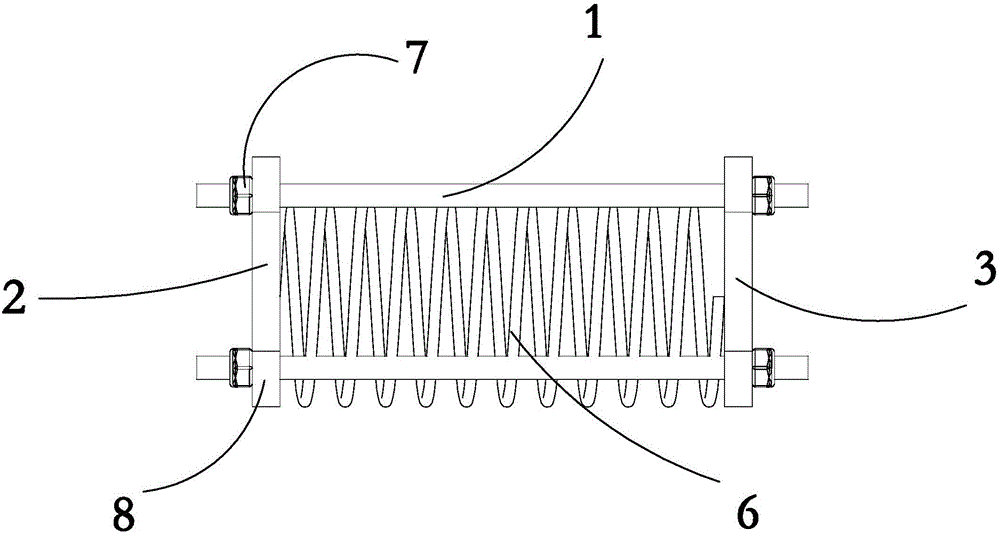

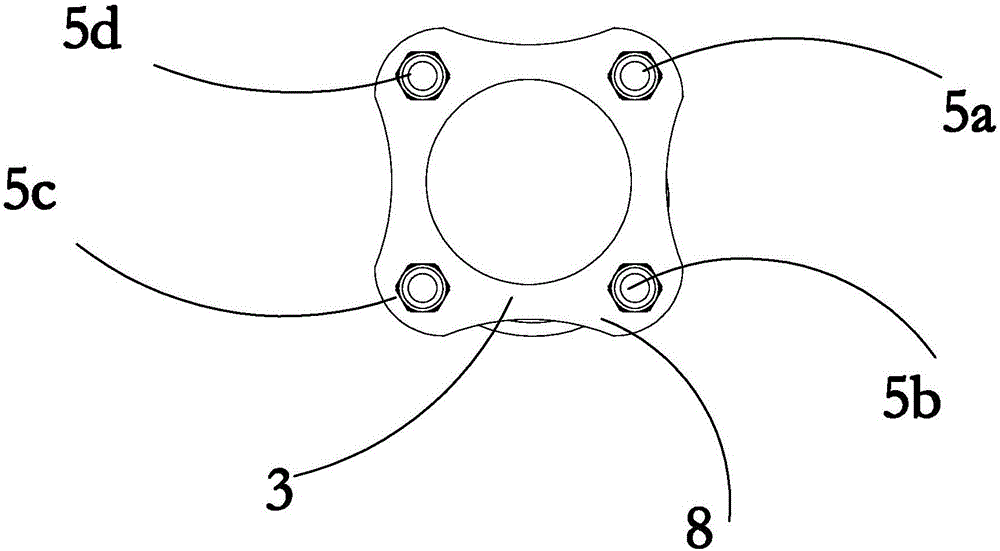

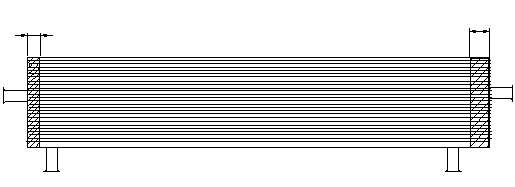

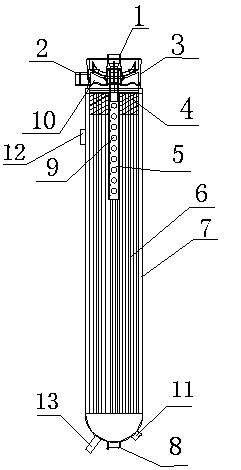

Hollow fibre membrane element

InactiveCN104209005ARelieve stressImprove cleaning effectSemi-permeable membranesMembranesHollow fibre membraneEngineering

A hollow fibrous membrane element comprises a pressure-bearing housing (7), and hollow fibrous membranes (6), and a water distributing pipe (5). A head sealing cover (3) is disposed at one end of the pressure-bearing housing (7). The head sealing cover (3) is used for fixing the water distributing pipe (5) and sealing the pressure-bearing housing (7). A housing liquid port (8) is disposed in the pressure-bearing housing (7). A cover head liquid port (2) is disposed in the head sealing cover (3). One end of each hollow fibrous membrane (6) is fixed with the pressure-bearing housing (7). The interior of the hollow fibrous membrane (6) communicates with the cover head liquid port (2). The other end of each hollow fibrous membrane (6) is sealed. Each hollow fibrous membrane (6) is radially distributed in the pressure-bearing housing (7).

Owner:ZHEJIANG CREATION ENVIRONMENT TECH +1

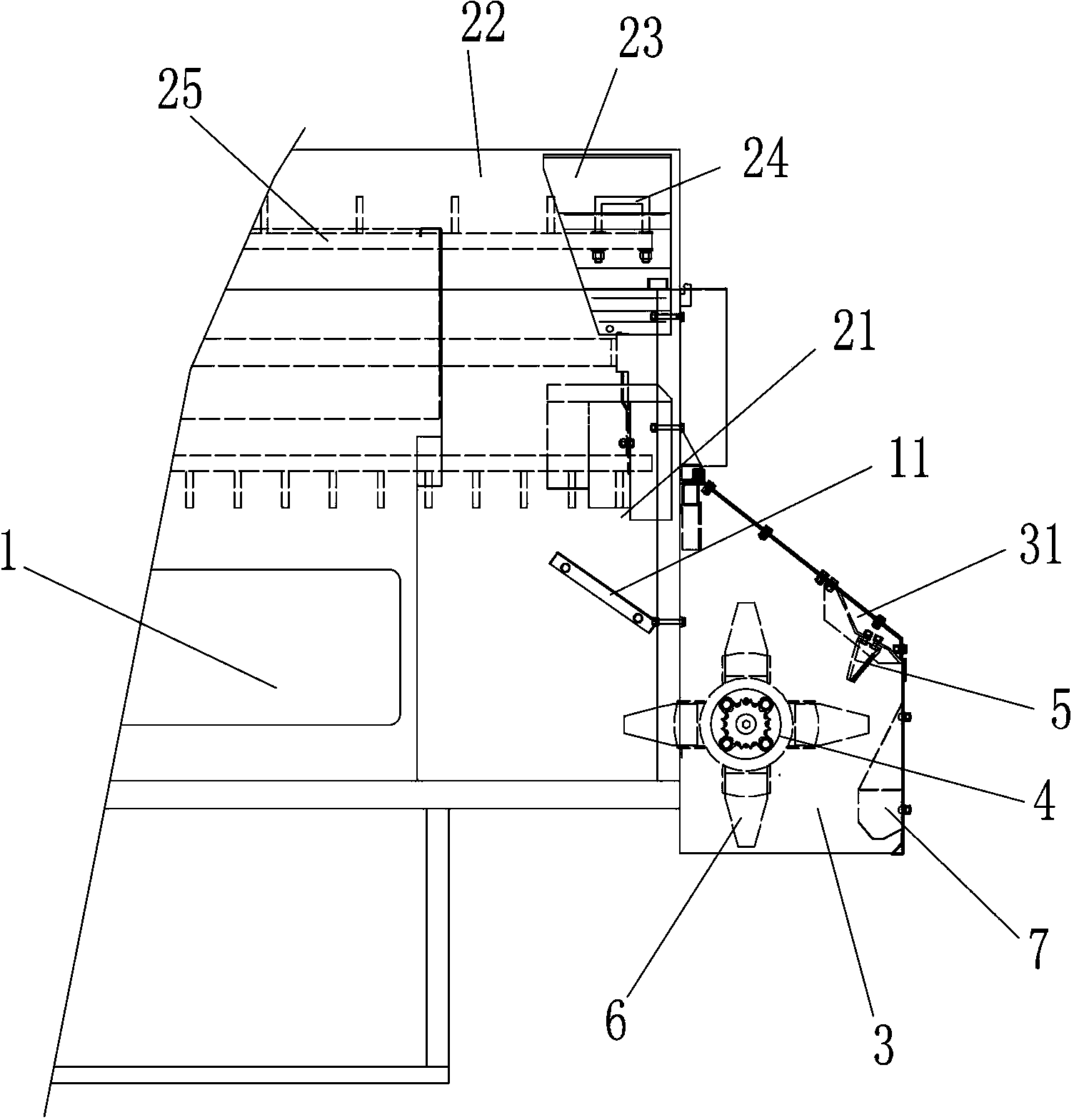

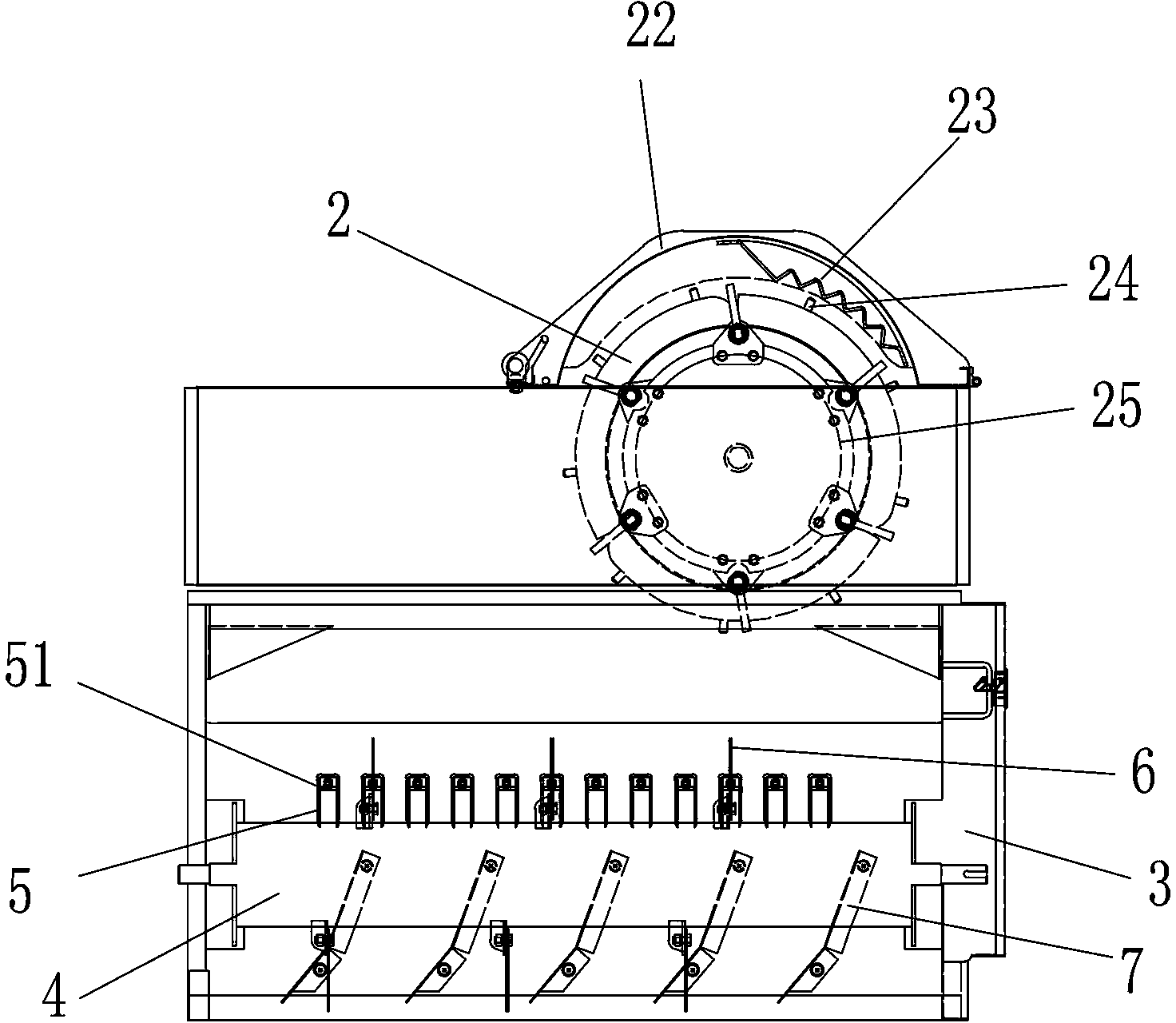

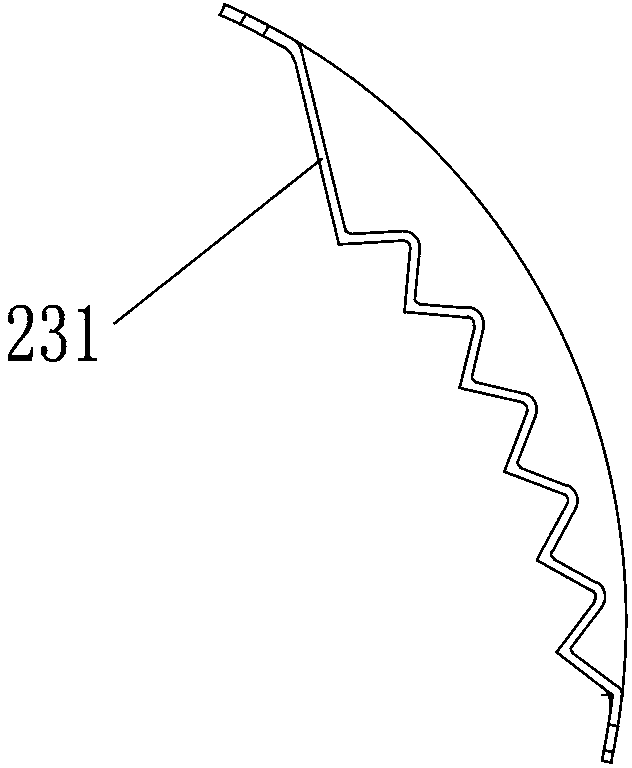

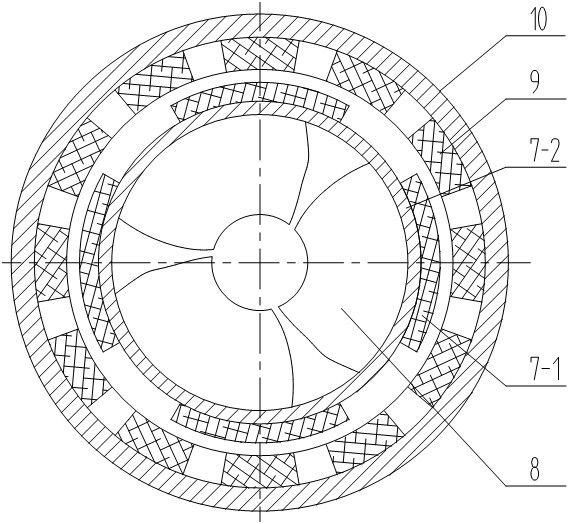

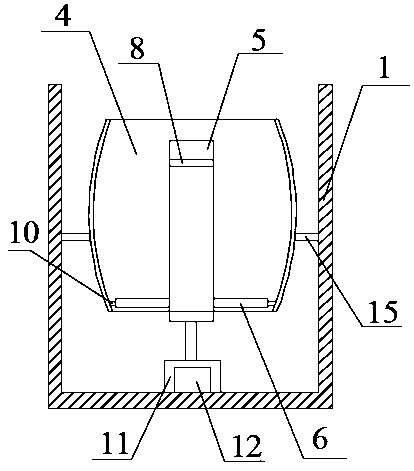

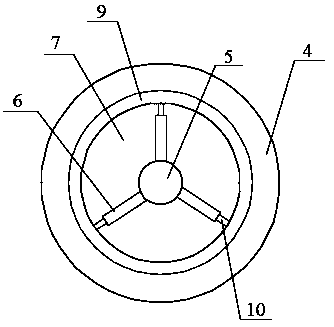

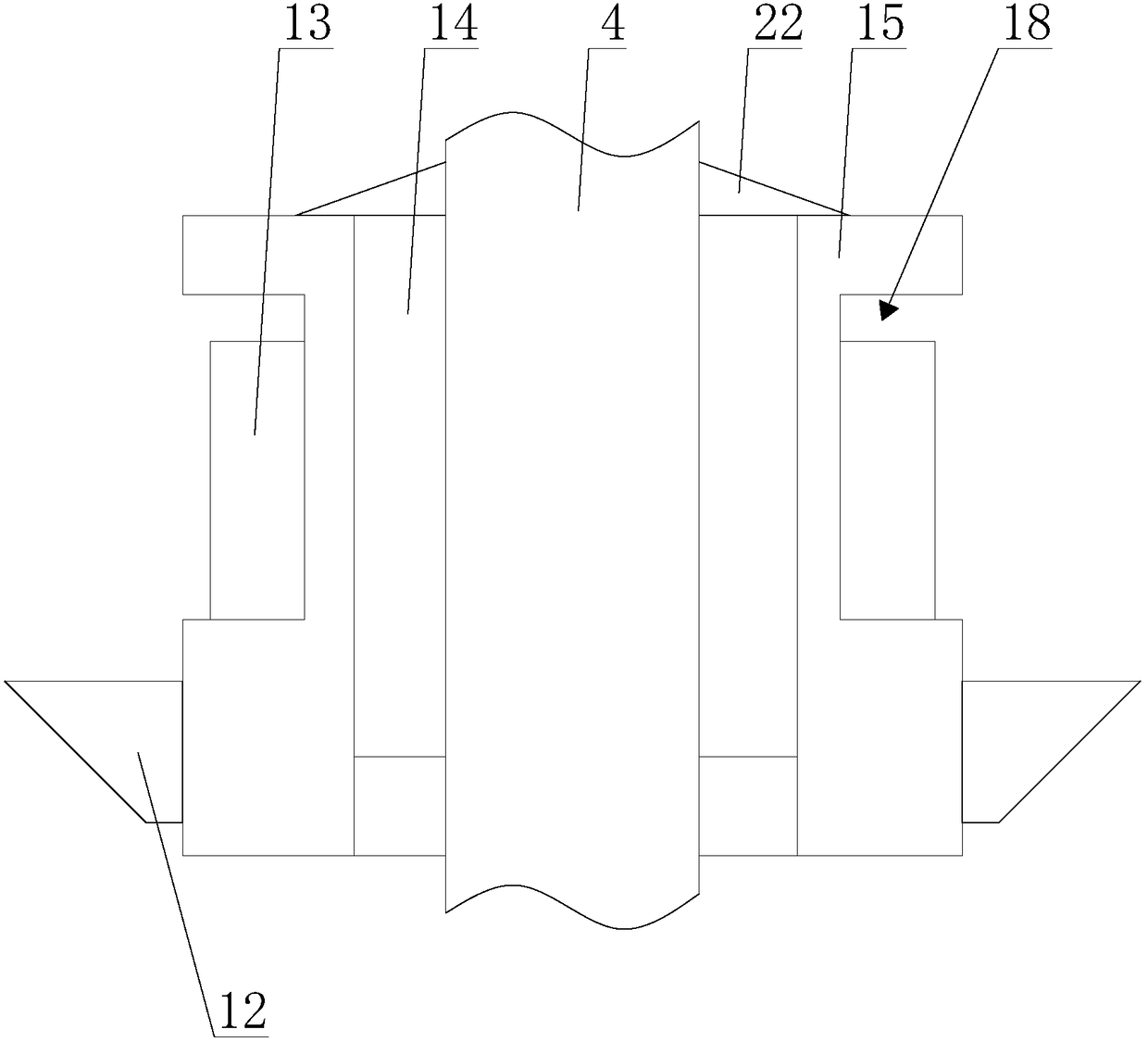

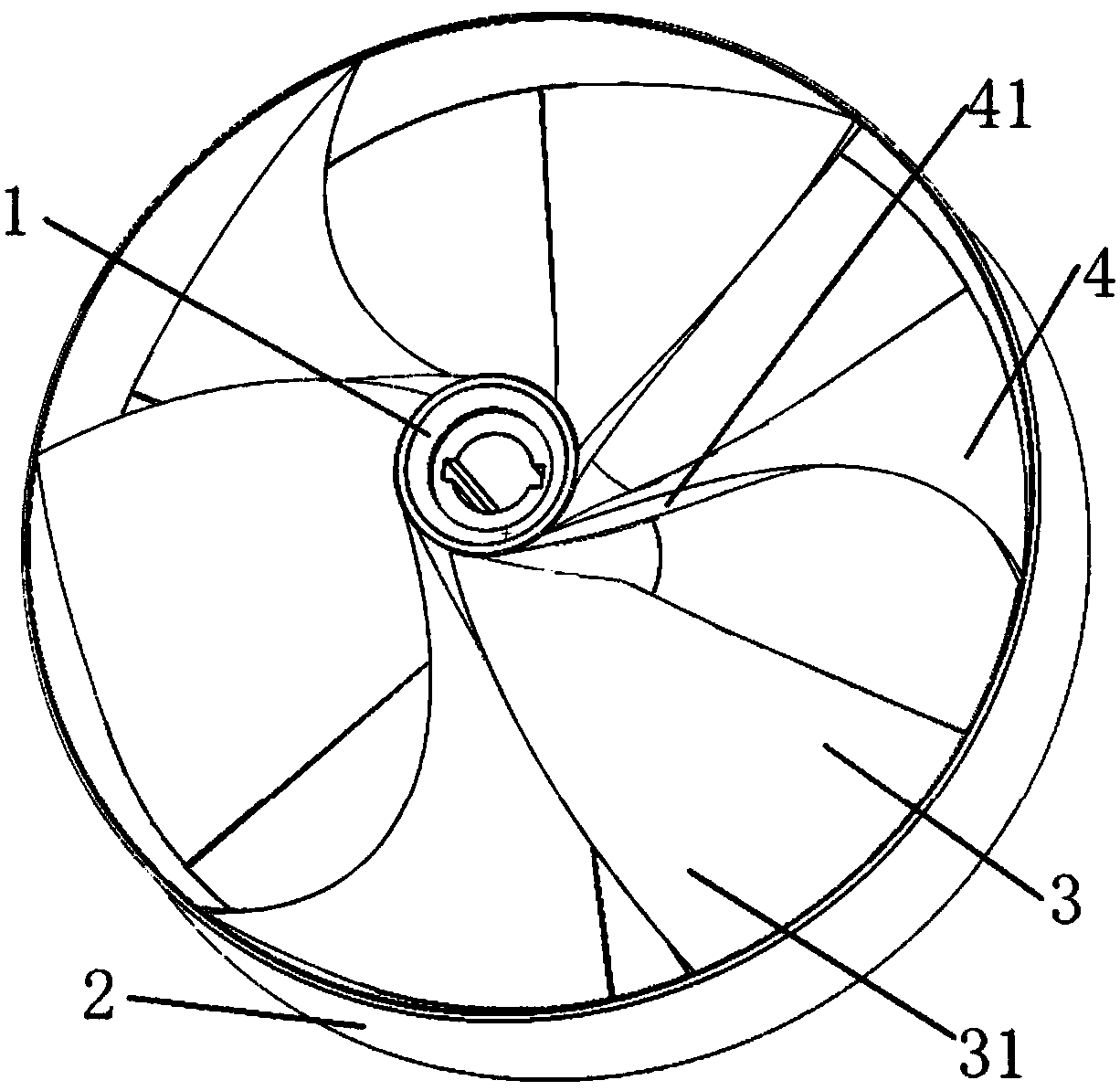

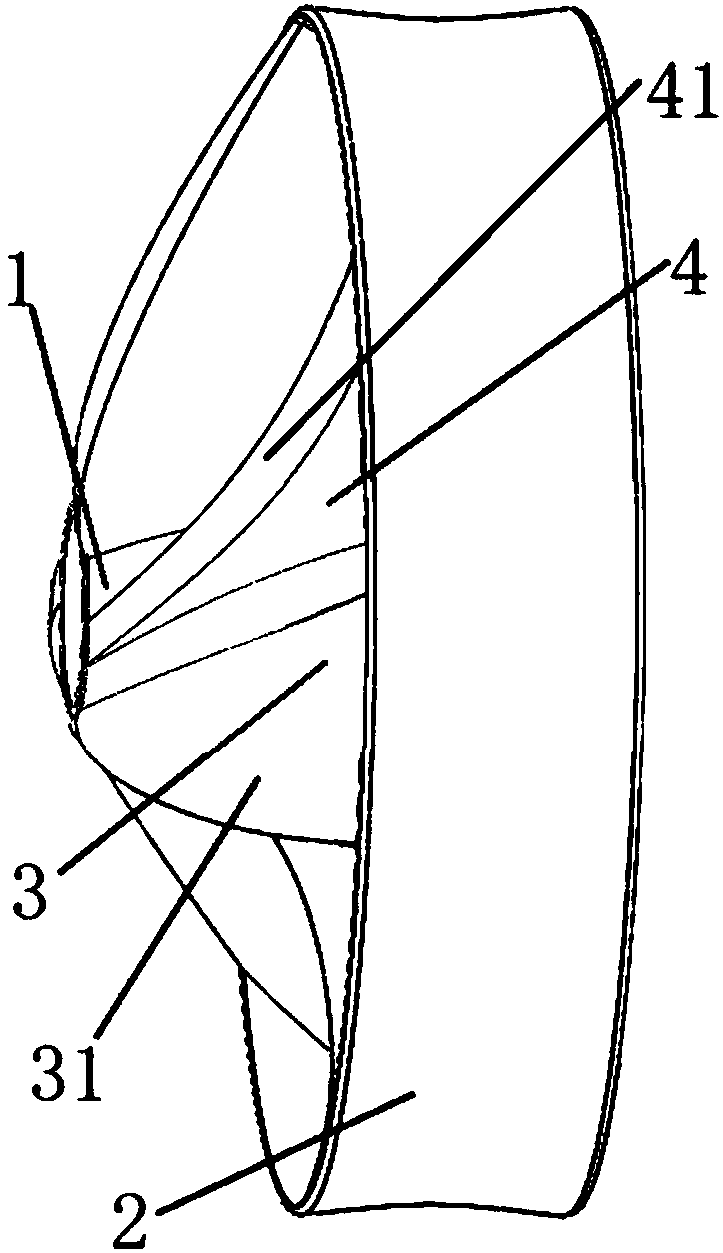

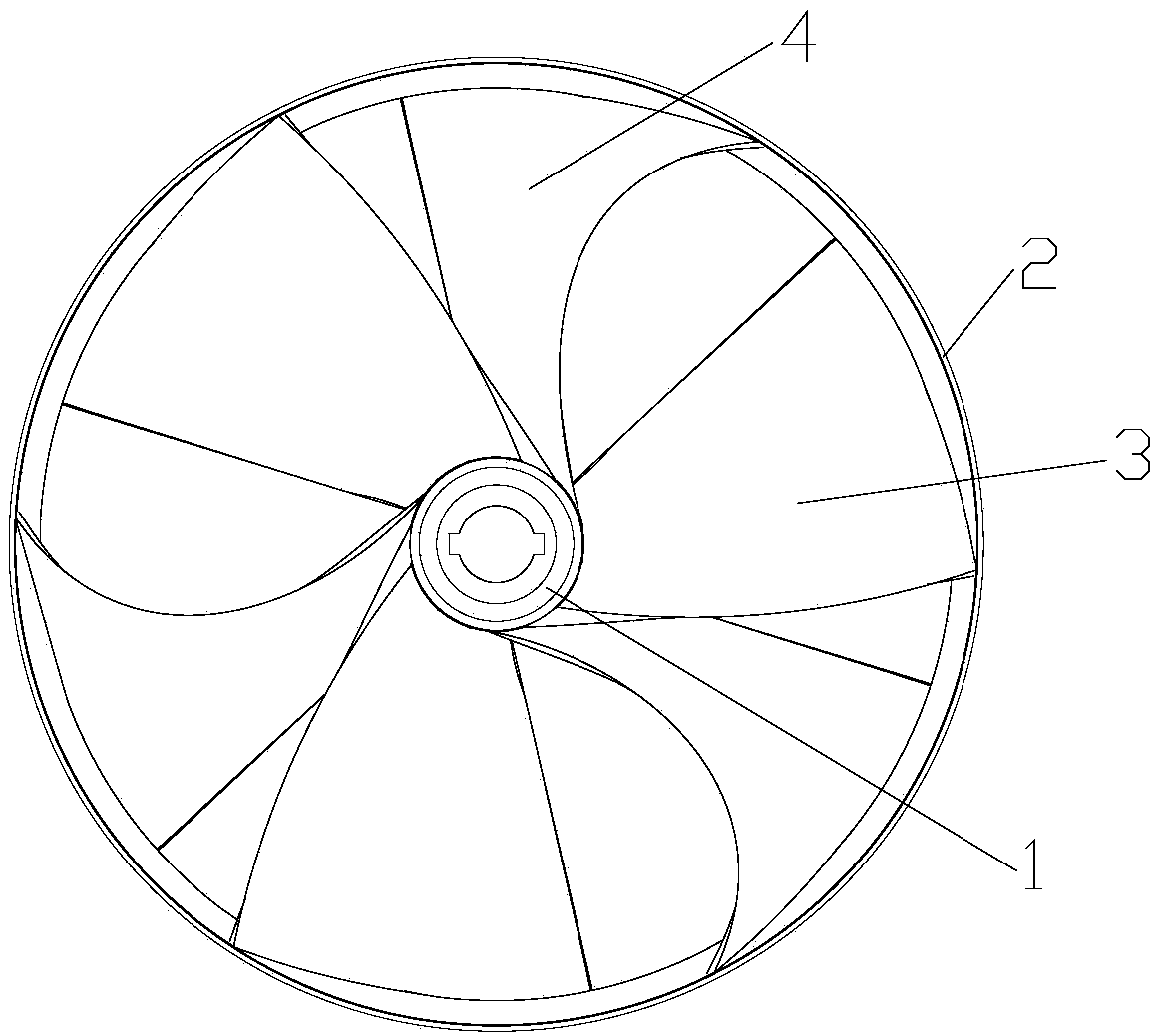

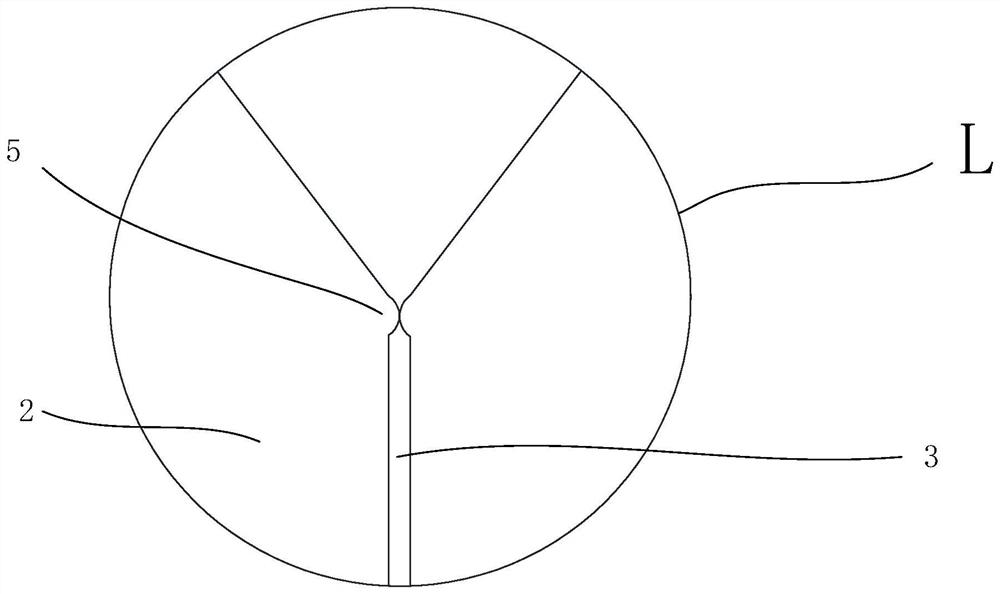

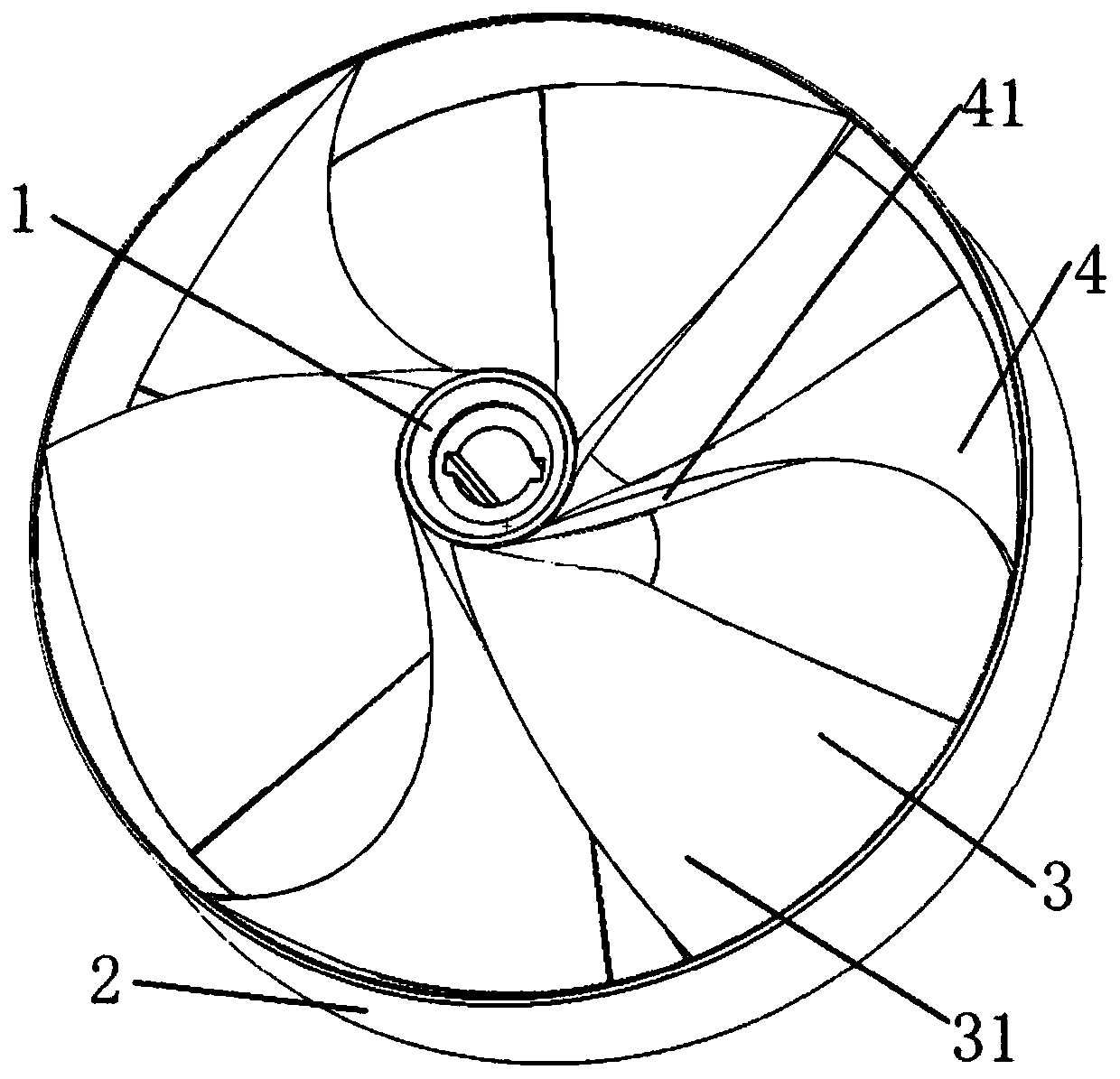

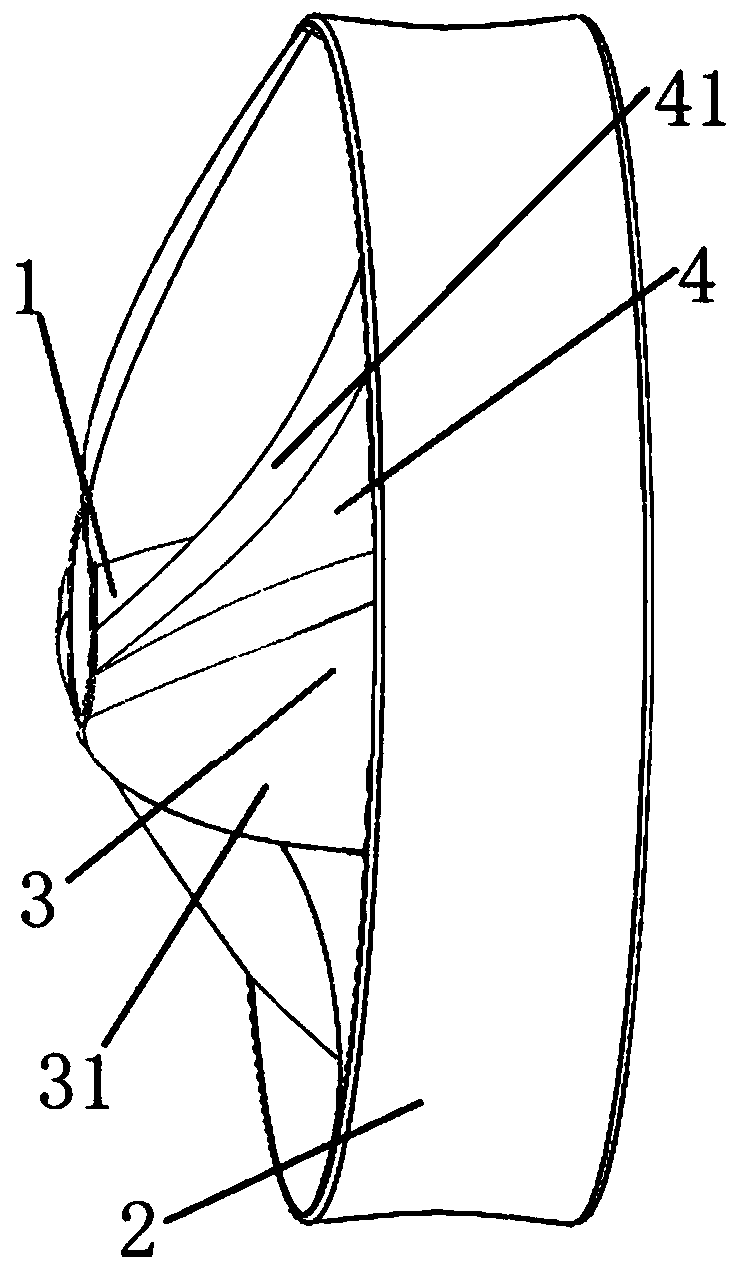

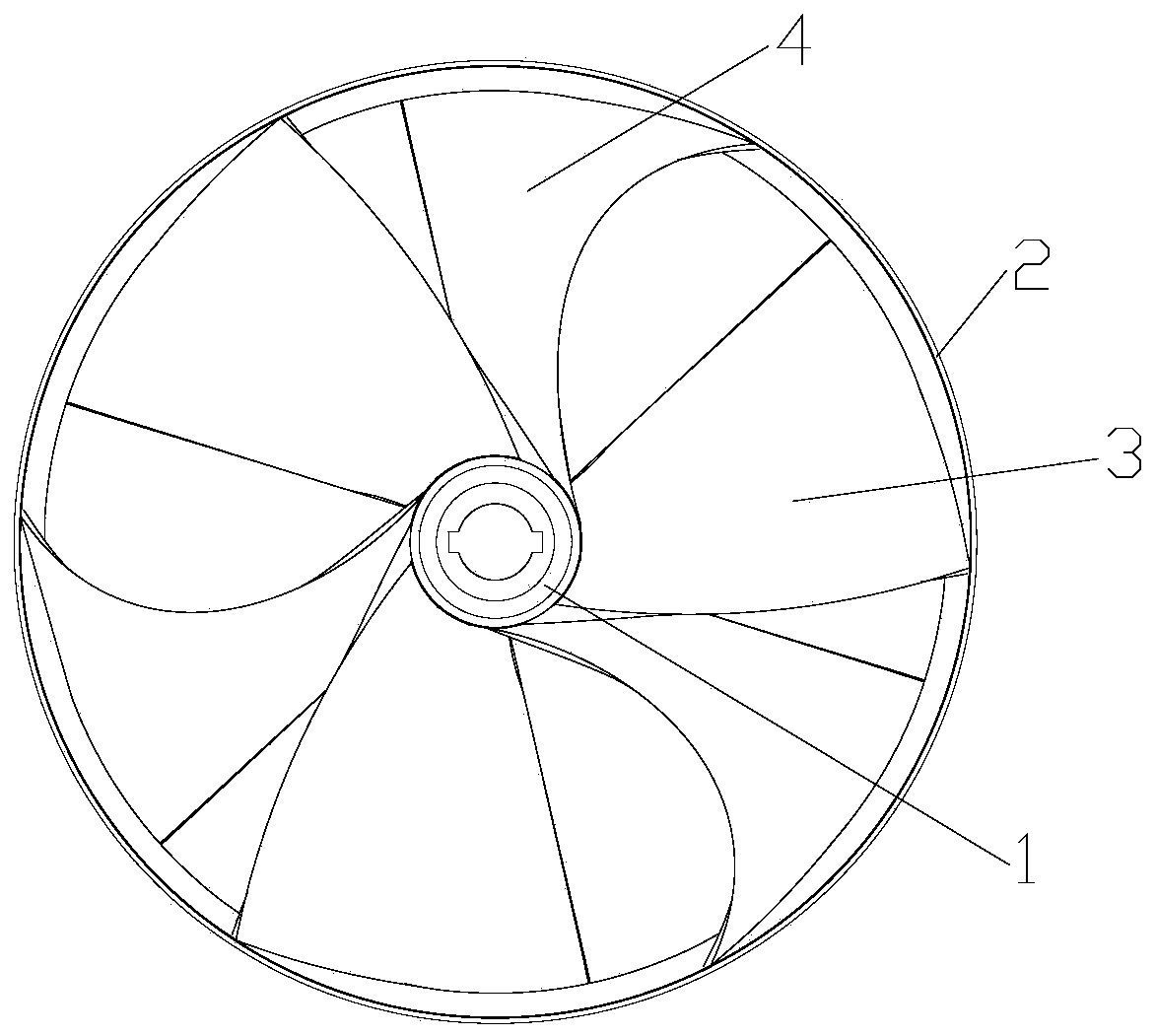

Safe and energy-saving type propeller

The invention discloses a safe and energy-saving type propeller. The safe and energy-saving type propeller comprises a propeller hub serving as an inner ring and a protective ring serving as an outerring. The propeller hub and the protective ring are arranged coaxially. Three sets of propeller blades are evenly distributed between the propeller hub and the protective ring. Each propeller blade isof an arc-shaped curved surface structure, wherein a certain inclination angle is formed between the arc-shaped curved surface structure and the movement direction of the propeller. Blade roots of the propeller blades are connected with the propeller hub. Blade tips of the propeller blades are connected with the inner side surface of the protective ring. The protective ring is of an arc-shaped symmetrical round ring structure with the middle being concave inwards. The axial length of the propeller hub is larger than that of the protective ring. The front end face of the protective ring is arranged between the front end face and the rear end face of the propeller hub. The rear end face of the propeller hub is arranged between the front end face and the rear end face of the protective ring.Each set of propeller blades comprises a main blade and an auxiliary blade which are arranged uniformly. The front section part of each main blade is a bending part which bends towards the rotating direction of the propeller blades. The front end part of each auxiliary blade is an arc-shaped concave part being concave backwards. The safe and energy-saving type propeller is simple in structure, high in safety and good in energy saving performance.

Owner:成都市陈式船舶研发有限公司

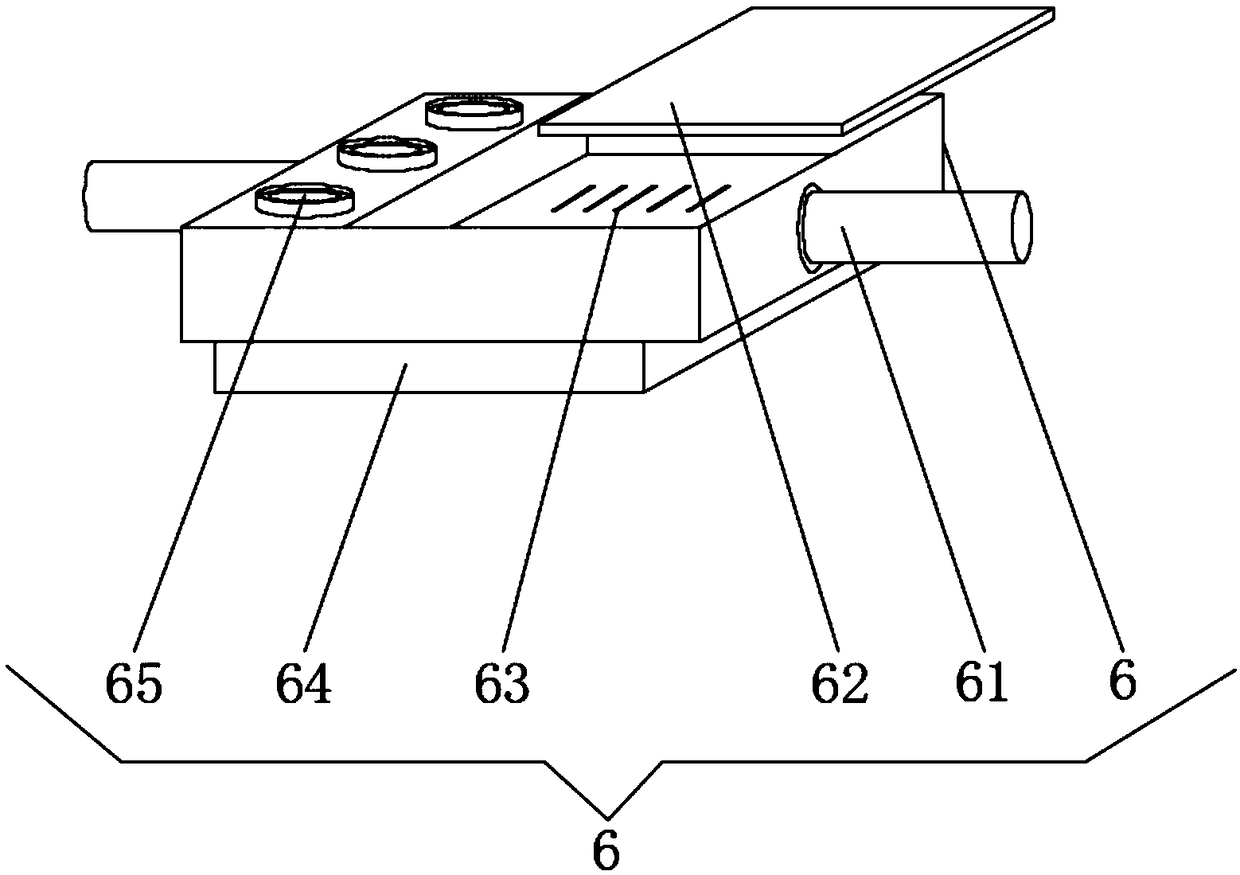

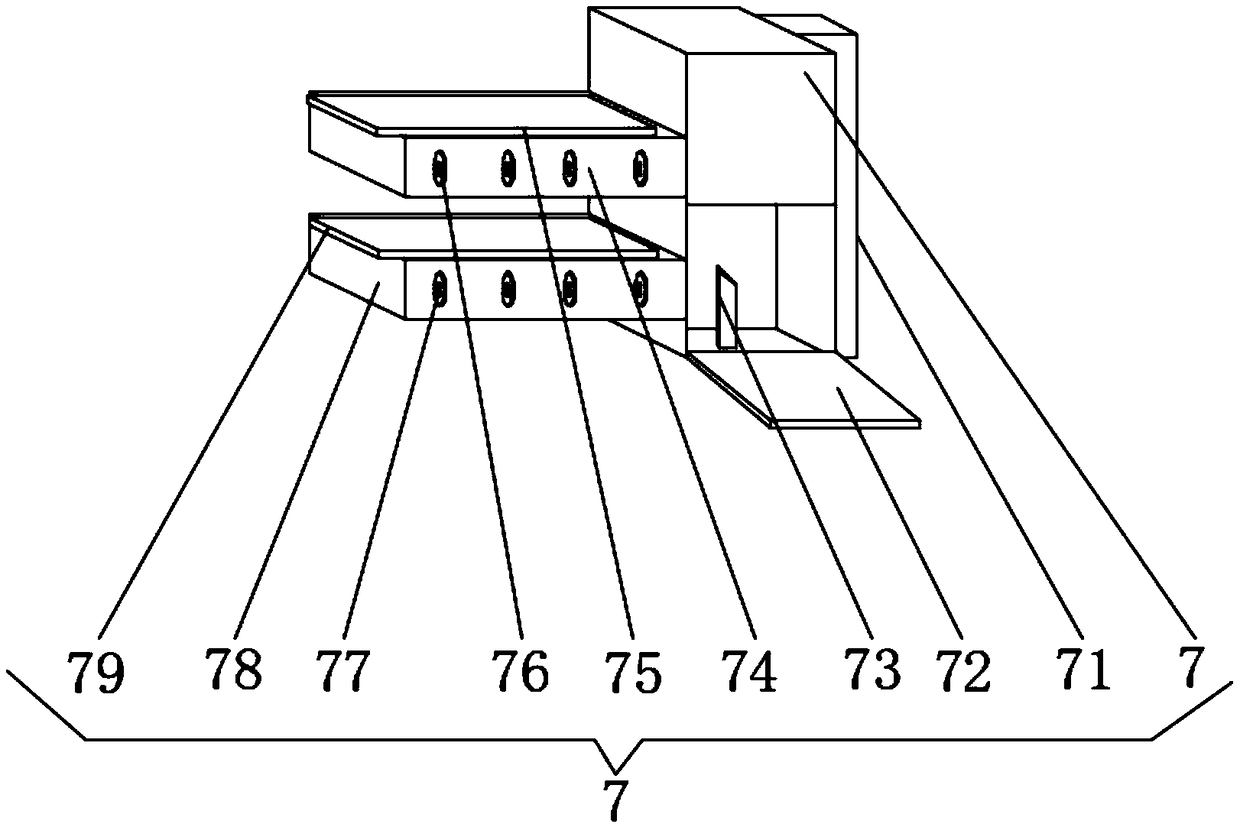

Multi-liquid-level pumping type sewage treatment device

InactiveCN111220415AEasy to fine-tuneMobile stabilityWithdrawing sample devicesTreatment involving filtrationBuoyant flowEngineering

The invention relates to the field of sewage treatment, in particular to a multi-liquid-level pumping type sewage treatment device. The multi-liquid-level pumping type sewage treatment device comprises a horizontally-arranged movable mounting plate, wherein arc-shaped striker plates are arranged at the two ends of the movable mounting plate; a lifting guide cylinder is vertically arranged in the middle of the movable mounting plate; a lifting mounting cylinder is vertically arranged in and matched with the lifting guide cylinder; bending mounting frames are arranged at the four corners of thelower end of the movable mounting plate correspondingly; and a buoyancy cavity is horizontally formed in the movable mounting plate. Through meshing transmission of a gear and a rack, the multi-liquid-level pumping type sewage treatment device can control the liquid level height of sewage pumping, further can accurately control the sewage at the target liquid level, facilitates the fine treatmentof sewage, is stable in movement by axially rotating a spiral structure, reduces the probability that the device is wound by sundries, remarkably improves the liquid pumping efficiency of the device through synchronous liquid pumping by means of multiple groups of liquid pumping structures, and improves the operation stability of the device through guide coupling power supply.

Owner:陶李

A New Combined Harvester Chopping Device

The invention relates to the field of harvesters, in particular to a novel combined harvester shredding device. The novel combined harvester shredding device comprises a weed smashing rubbing plate arranged at the rear end of a top cover, rubbing teeth arranged on a tooth frame and matched with the weed smashing rubbing plate, and a weed smashing cutter assembly arranged below a material outlet. The weed smashing cutter assembly comprises a discharging frame arranged at the rear end of the rack, a frame cover arranged on the discharging frame, a discharging cavity located below the frame cover, a discharging cylinder arranged on the discharging frame and located in the discharging cavity, fixed cutters and movable cutters, wherein the fixed cutters are arranged on the discharging frame, and the movable cutters are arranged on the discharging cylinder. The material outlet is communicated with the discharging cavity, and a discharging port is formed in the bottom of the discharging frame. Through movement inertia of a threshing cylinder, straw or weeds to be discharged out are shredded through the rubbing force of the teeth and the rubbing plate for the first time and then separated. The straw or the weeds fall to be conveyed to the weed smashing cutter assembly to be shredded at last through the shredding action of the movable cutters and the fixed cutters, and then the straw or the weeds are discharged through the discharging port. The novel combined harvester shredding device is simple in structure, low in cost, convenient to install, good in shredding effect, low in weed winding rate and high in shredding efficiency.

Owner:曾联

A new energy vehicle air conditioning system that facilitates filter element replacement

ActiveCN108725131BImprove practicalityImprove replacement efficiencyAir-treating devicesVehicle heating/cooling devicesNew energyAutomobile air conditioning

The invention relates to a new energy resource automobile air conditioning system facilitating filter element replacement. The new energy resource automobile air conditioning system facilitating filter element replacement comprises a main body, a filter element, a replacement opening and two ventilation openings and also comprises a putaway mechanism and two packaging mechanisms, wherein the putaway mechanism comprises a guiding rod, a driving assembly, a sliding block, a supporting assembly, a fixing rod, a fixing sleeve, a power plate, a connecting rod, movable wheels, a first spring and a friction block, and each packaging mechanism comprises a supporting plate, a lifting rod, a first air cylinder, a second air cylinder, a material receiving cylinder, adhesive tapes, an adsorption assembly, a lifting sleeve, a blade and a second spring. According to the new energy resource automobile air conditioning system facilitating filter element replacement, the filter element can be automatically moved out of the main body through the putaway mechanism and meanwhile can be also moved into the main body, accordingly the filter element replacement efficiency of the air conditioning system is improved, the adhesive tapes can be adhered to two sides of the filter element, accordingly the probability can be reduced that dust on the filter element falls into an automobile, and the inside ofthe new energy resource automobile can be kept clean.

Owner:苏州市相城区黄桥工业园经济发展有限公司

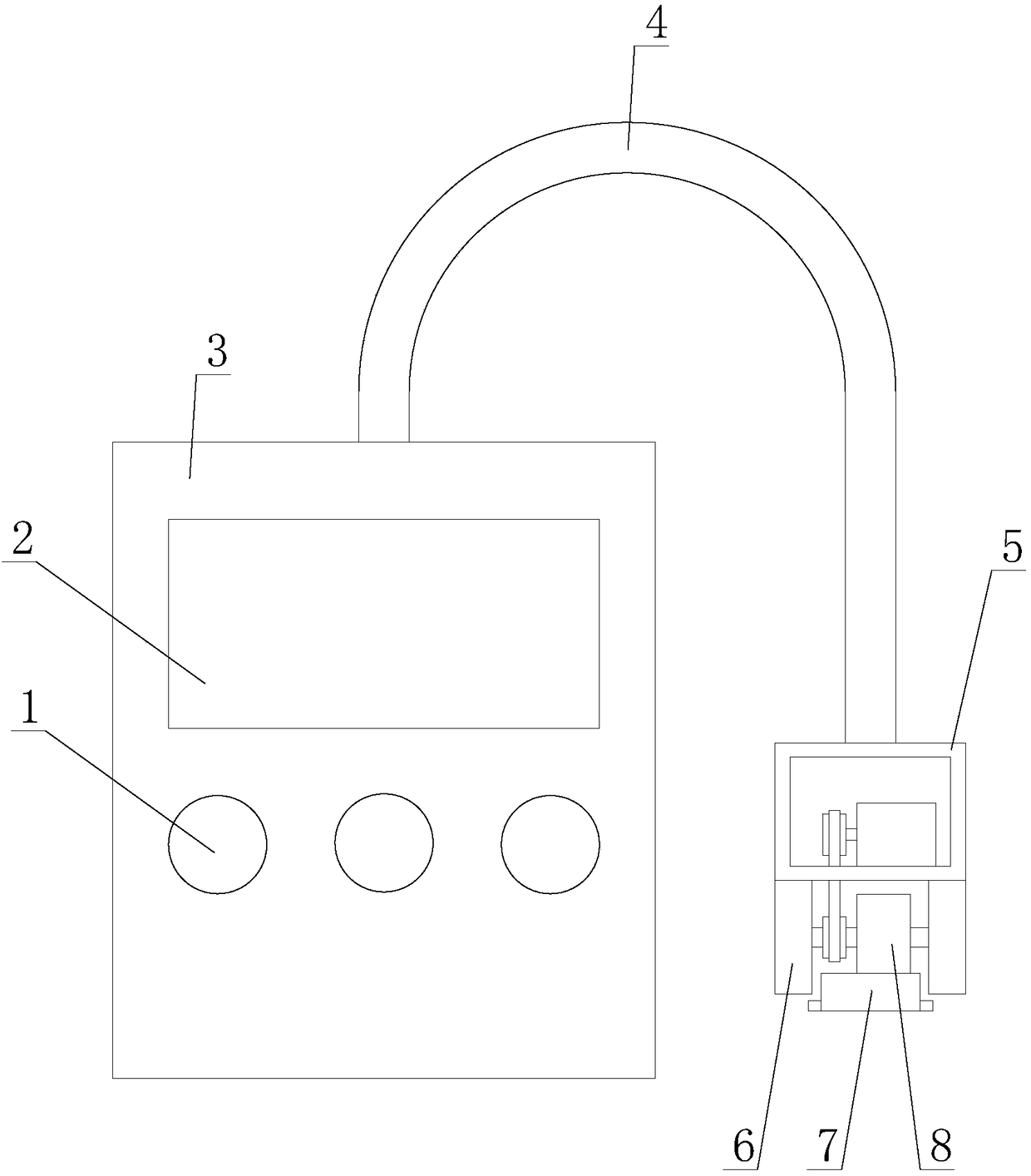

Combined medical guide wire fixing clamp

ActiveCN114306890ASave medical resourcesAvoid unnecessary operationsGuide wiresStructural engineeringPush switch

The invention discloses a combined medical guide wire fixing clamp which comprises a bottom plate, the bottom plate is provided with a clamping device, the clamping device comprises two clamping plates arranged side by side, a gap for retaining a guide wire is formed between the two clamping plates, and the bottoms of the two clamping plates are rotatably connected; the button switch is movably connected with the clamping device and used for controlling opening and closing of the clamping device; the magnetic connecting devices are arranged on the side edges of the bottom plates and used for rapidly and magnetically connecting the multiple bottom plates; and the bonding layer is arranged on the bottom surface of the bottom plate in a covering manner and is used for adhering the fixing clamp to a table top or a bed sheet.

Owner:FUWAI HOSPITAL CHINESE ACAD OF MEDICAL SCI & PEKING UNION MEDICAL COLLEGE

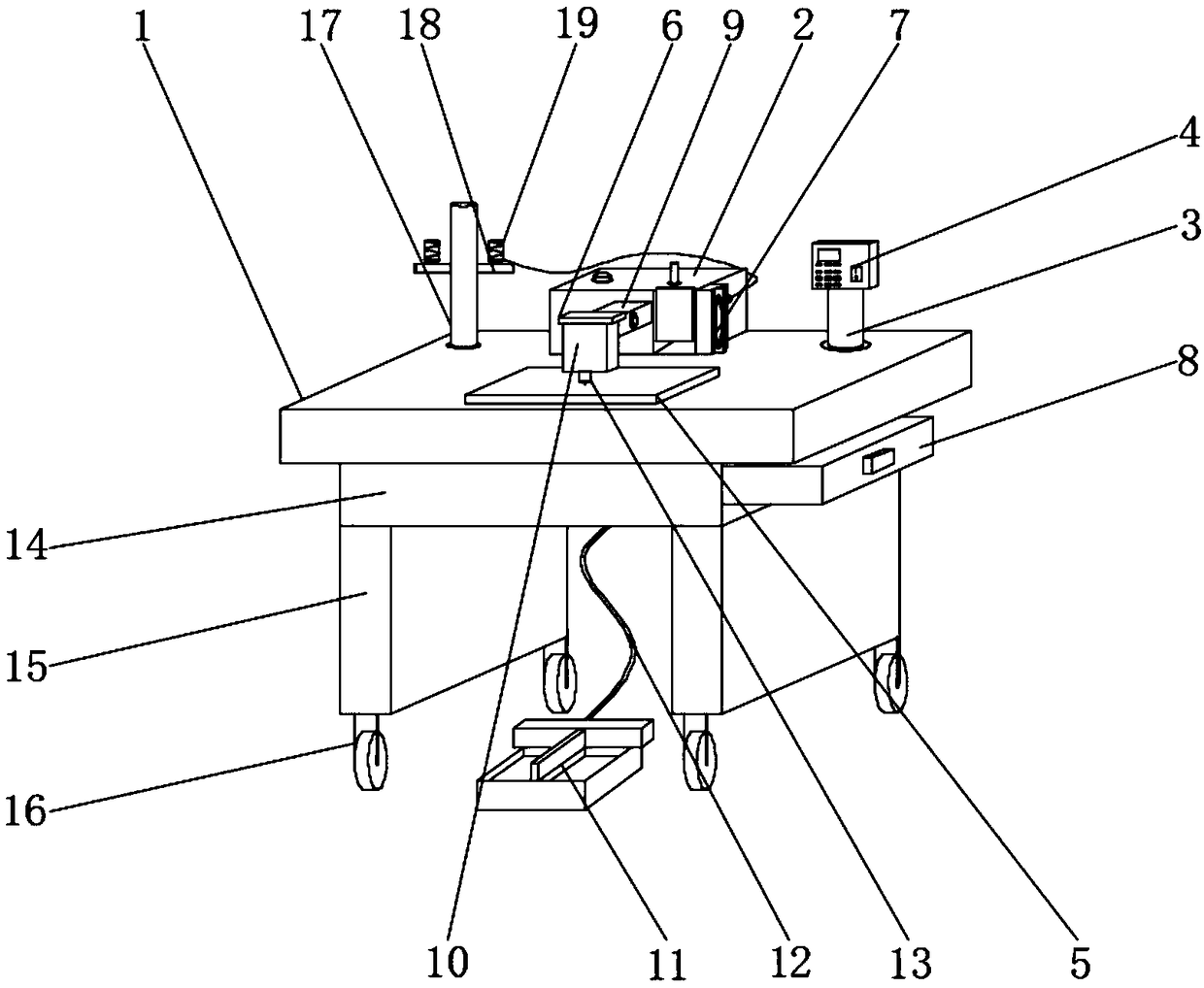

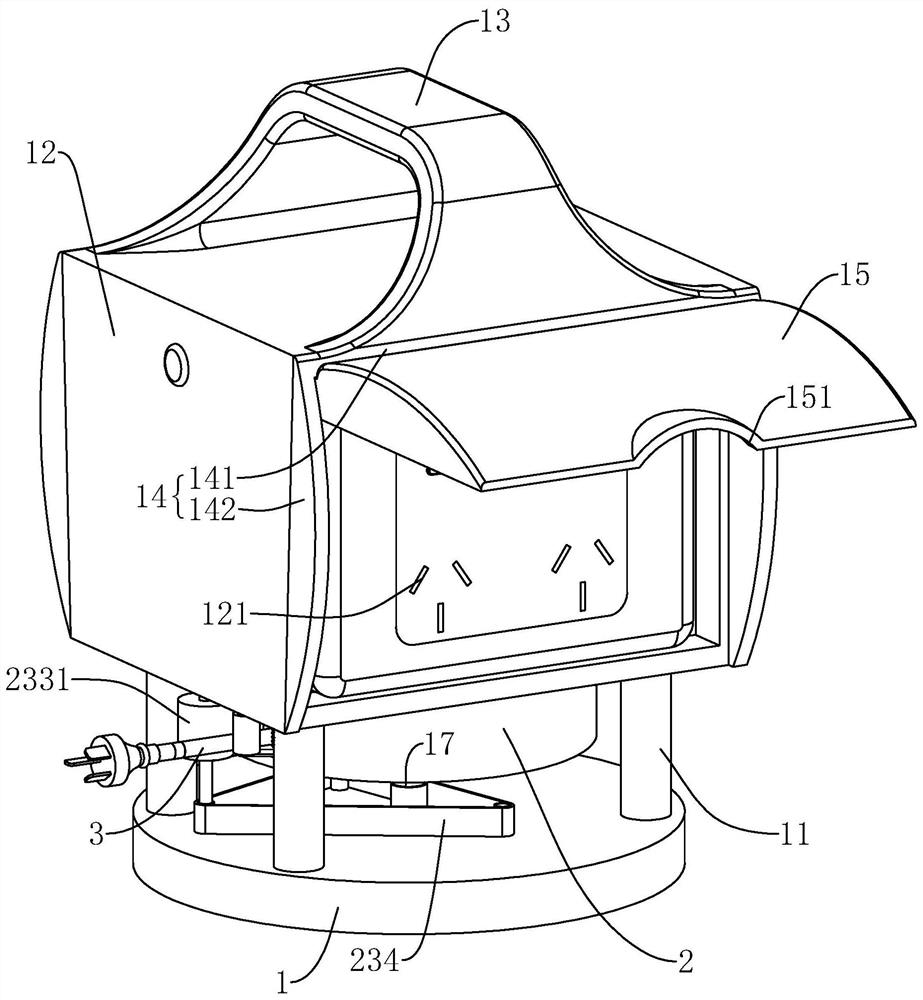

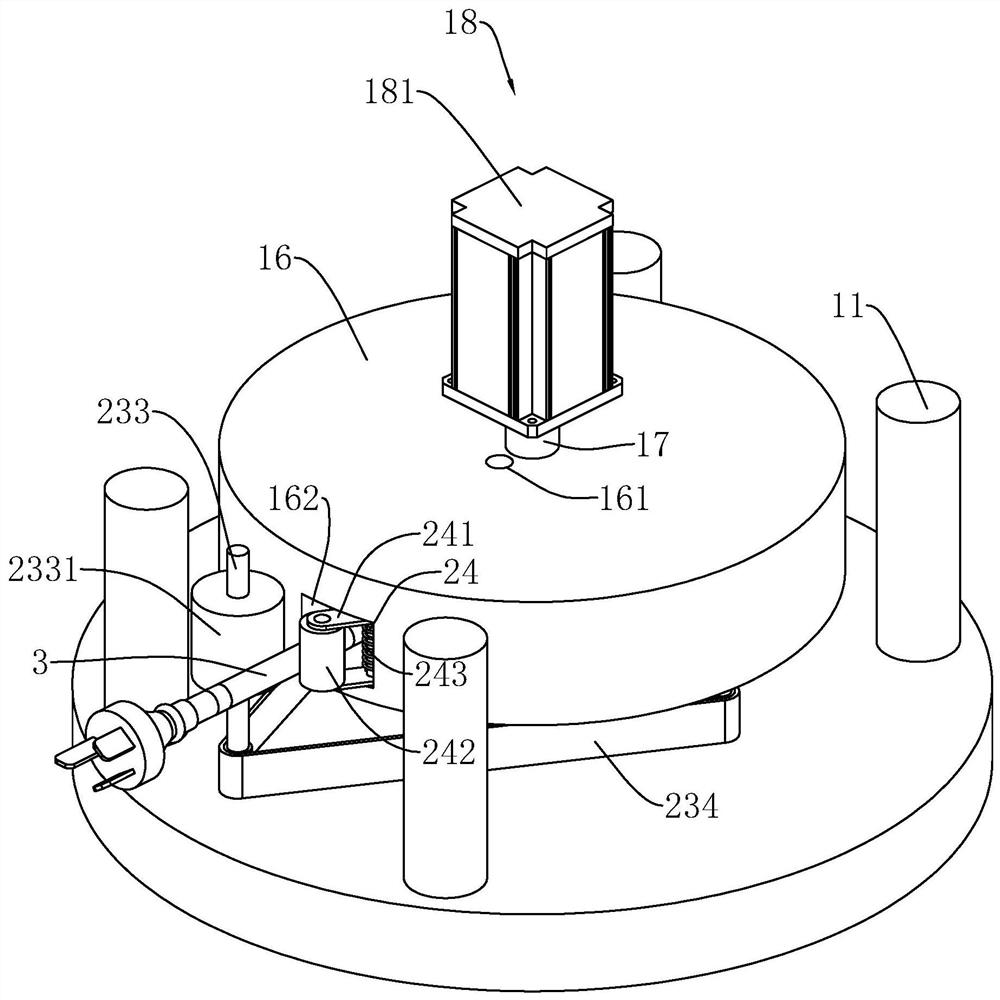

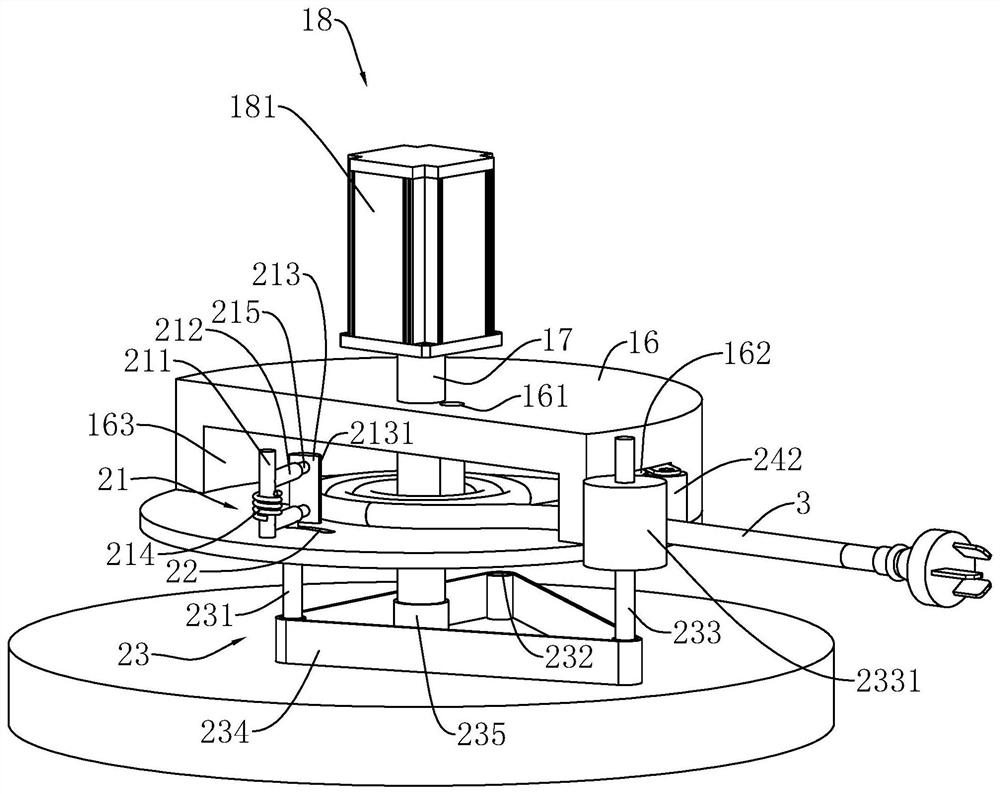

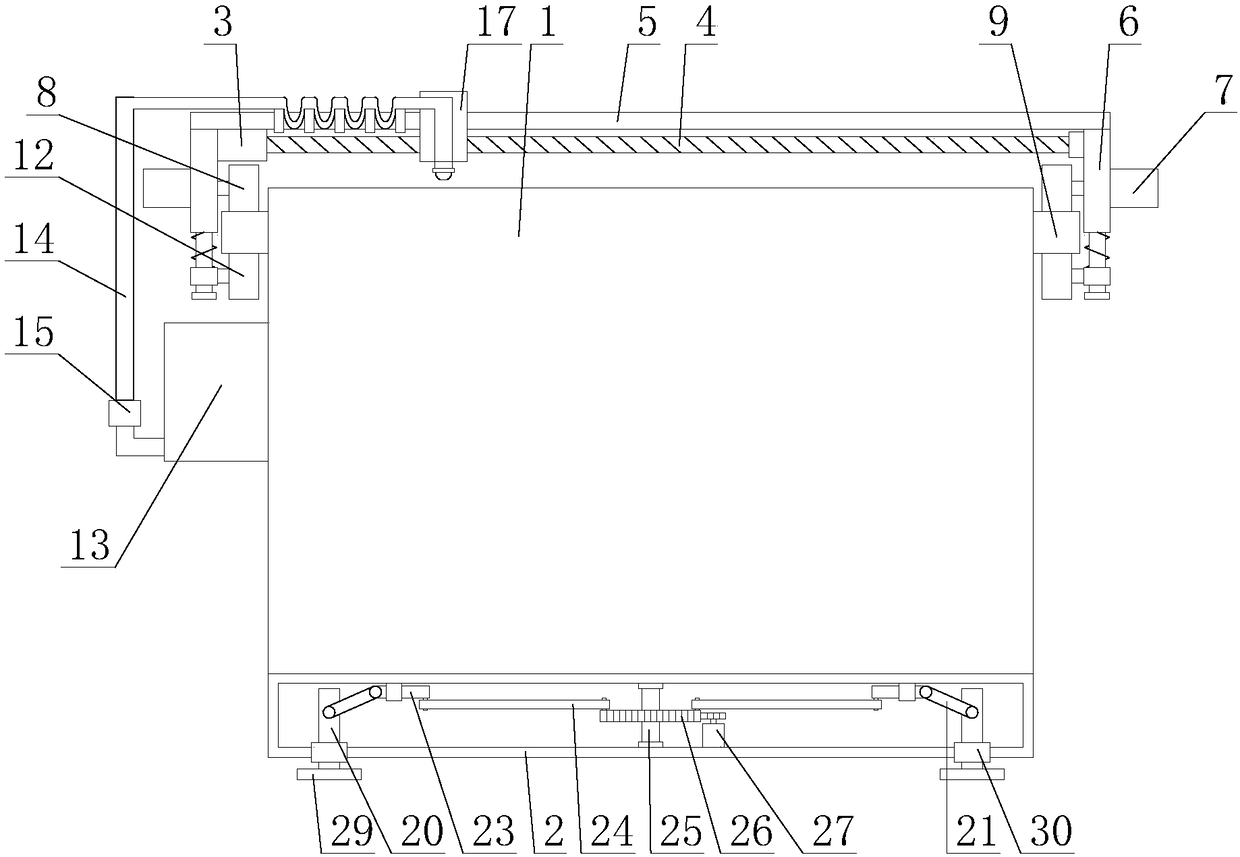

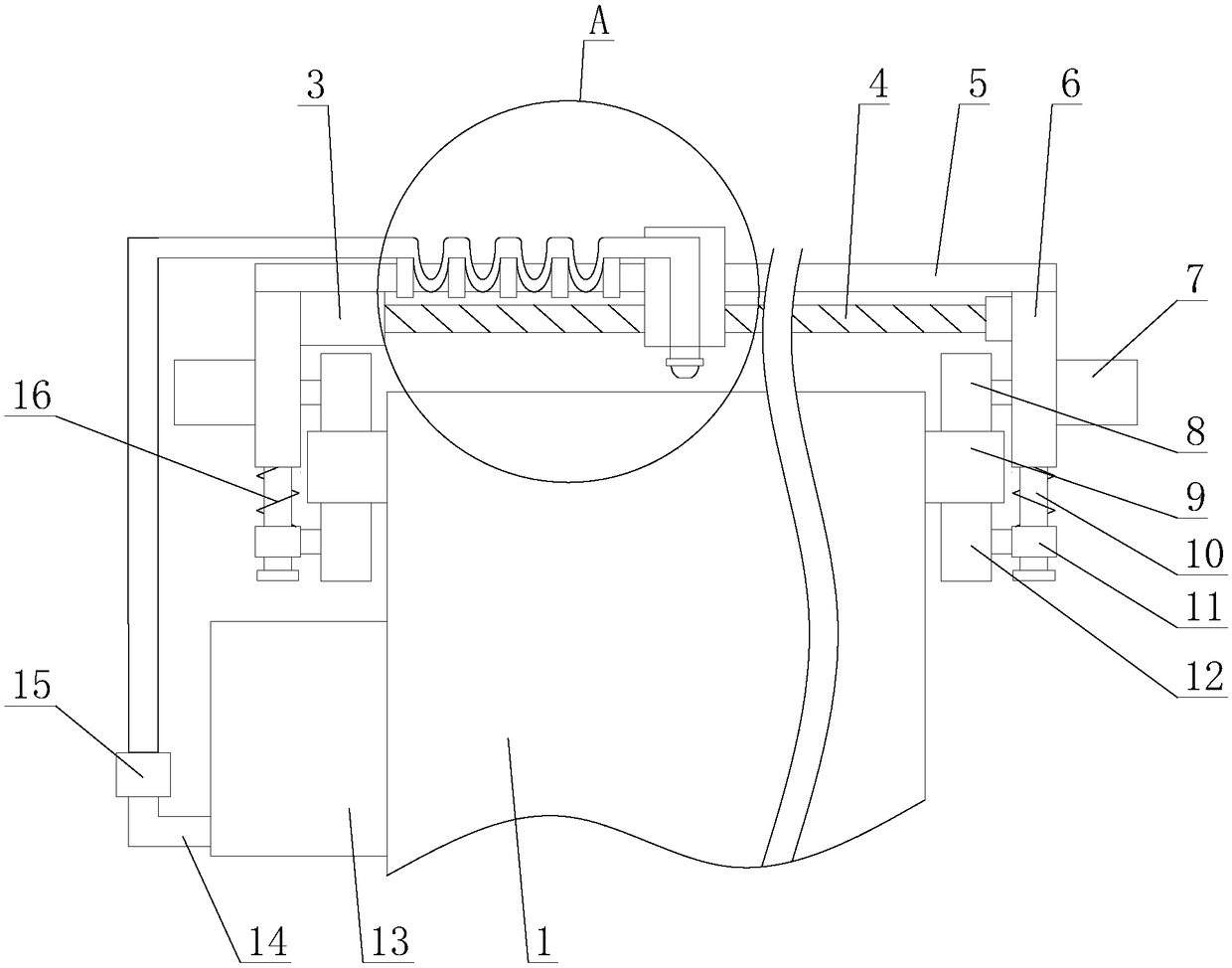

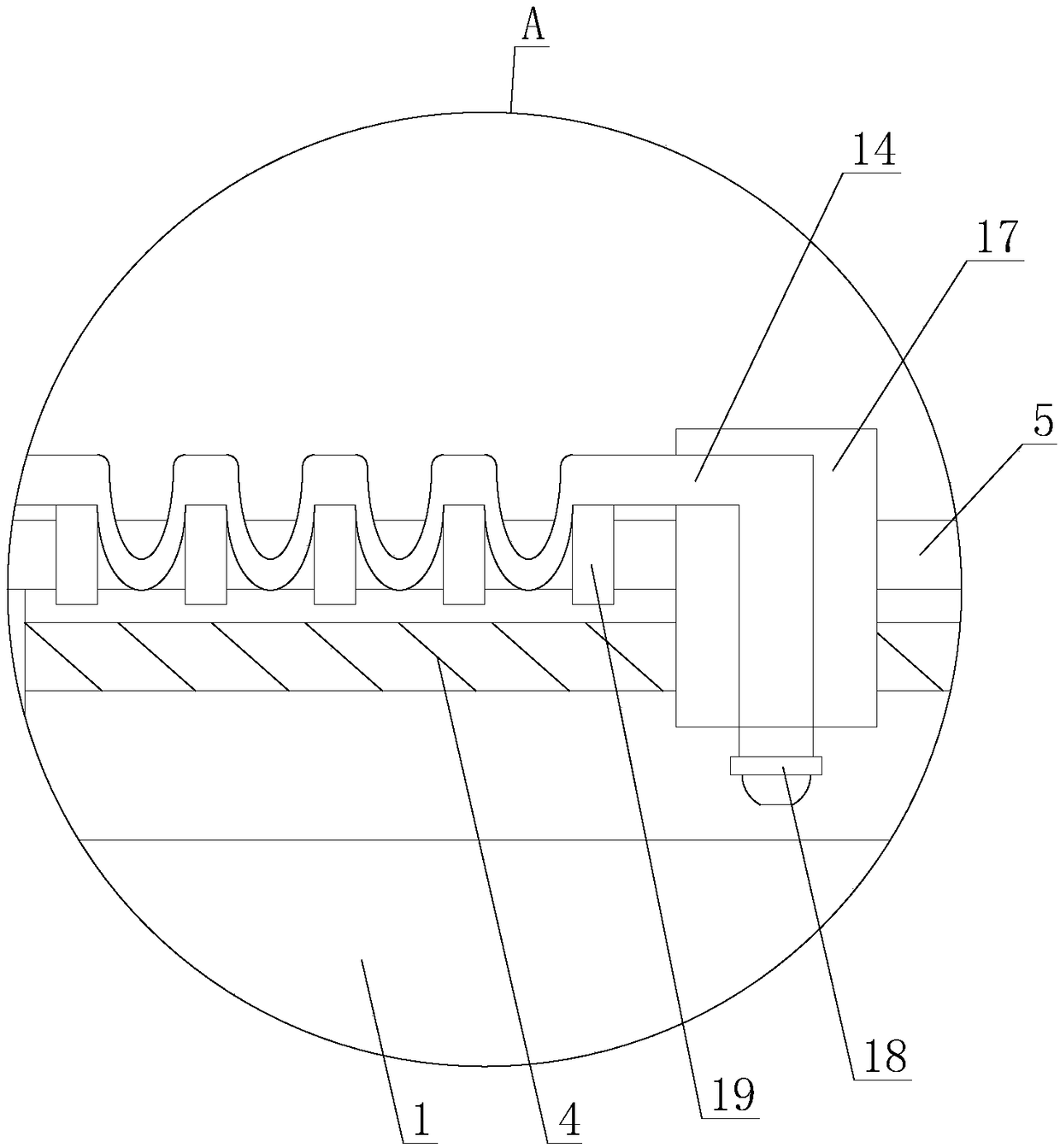

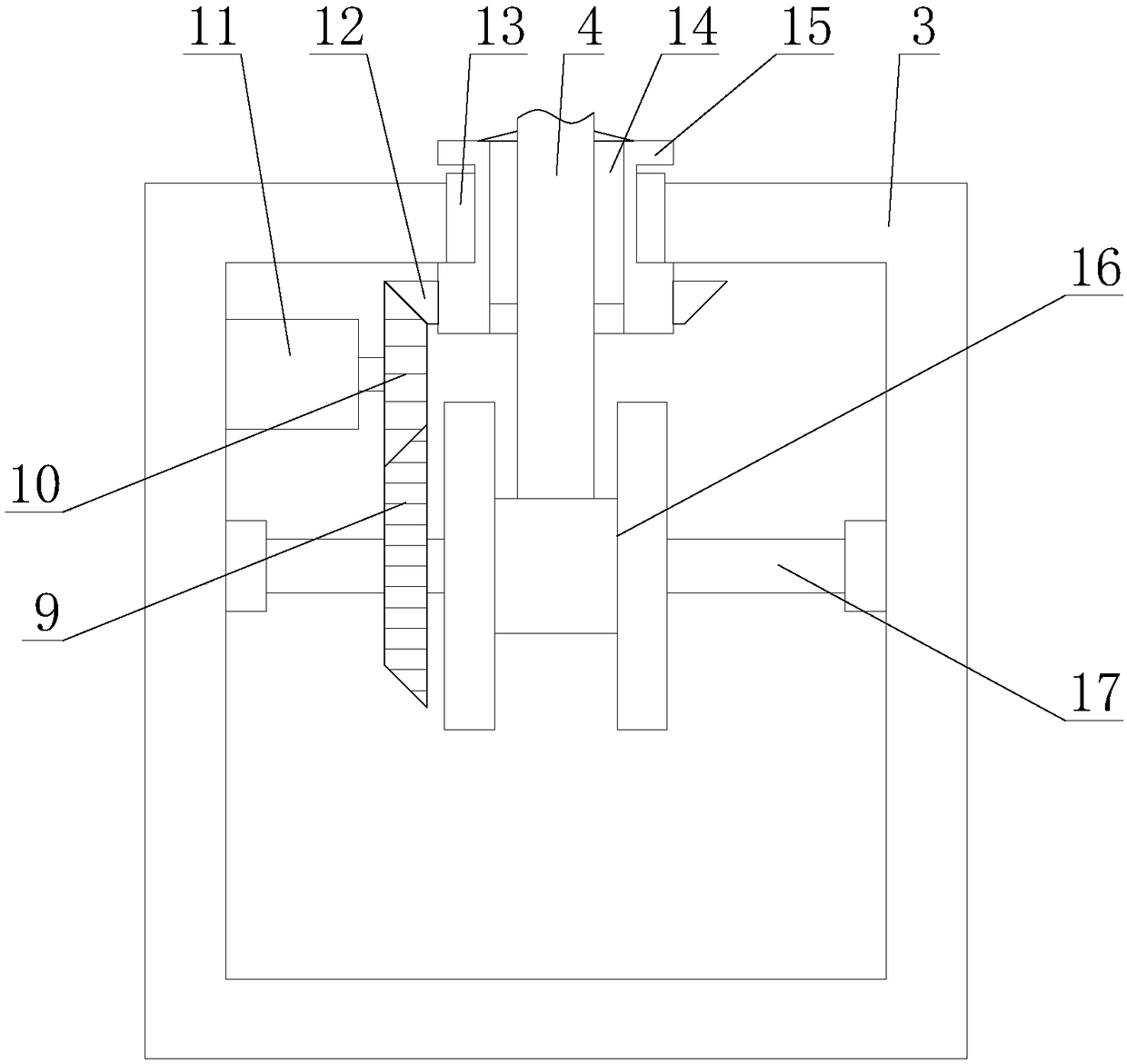

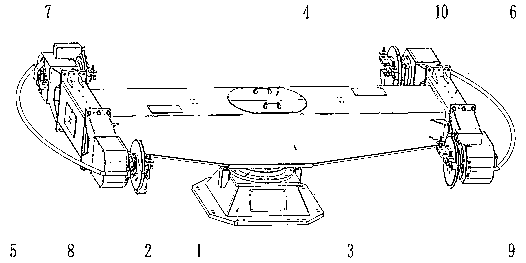

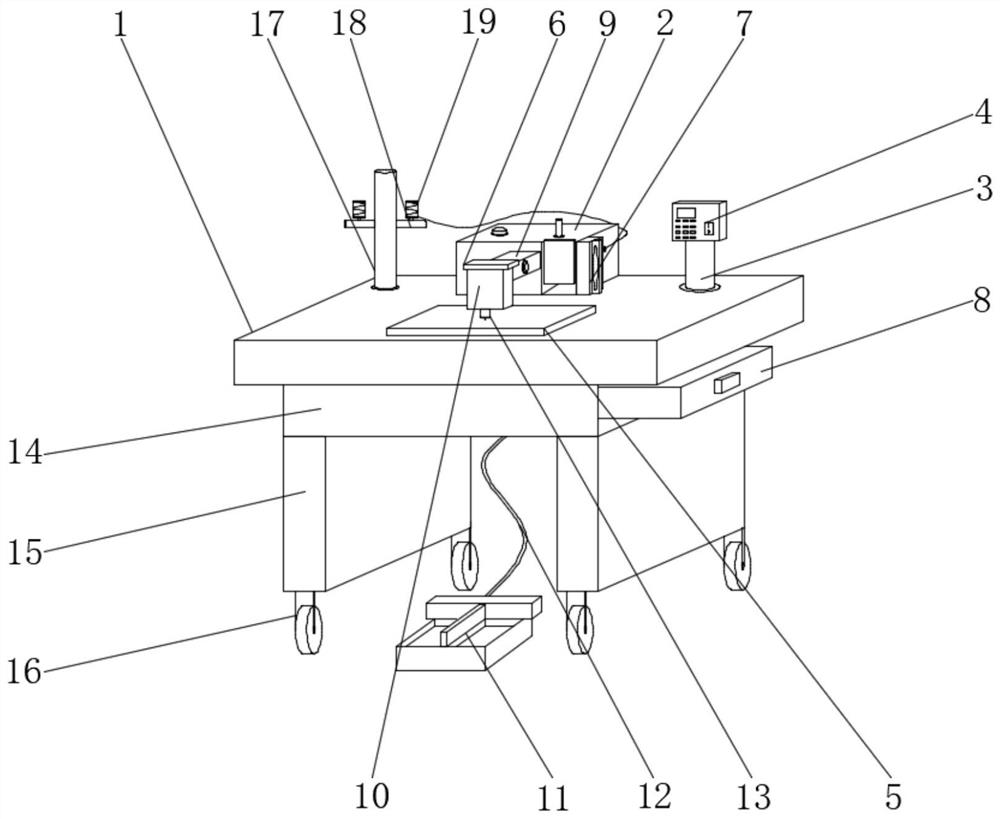

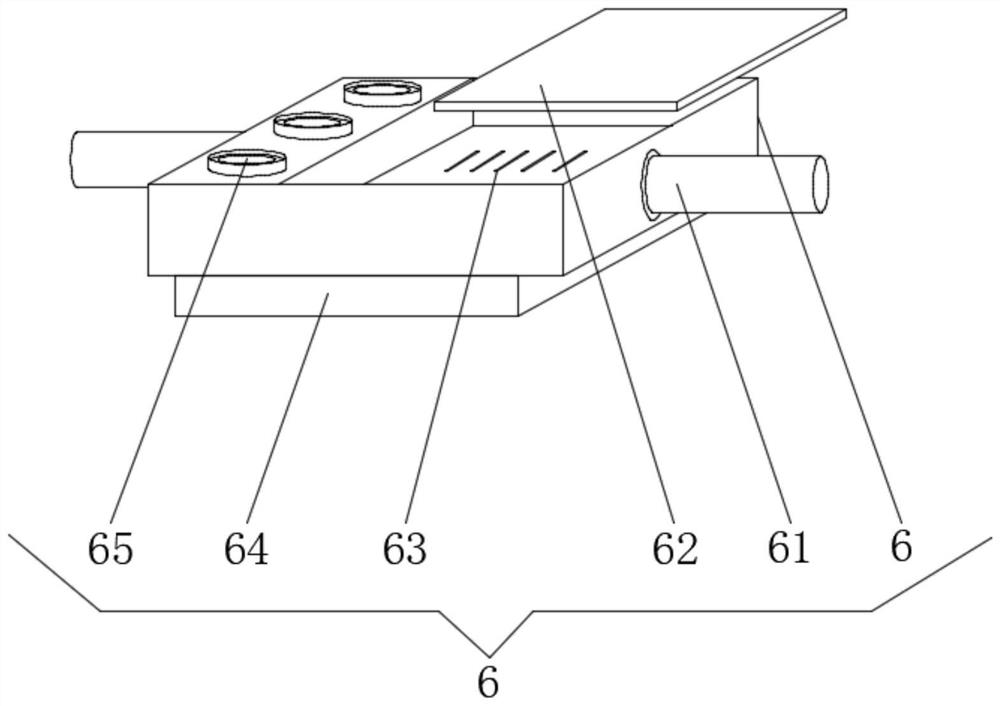

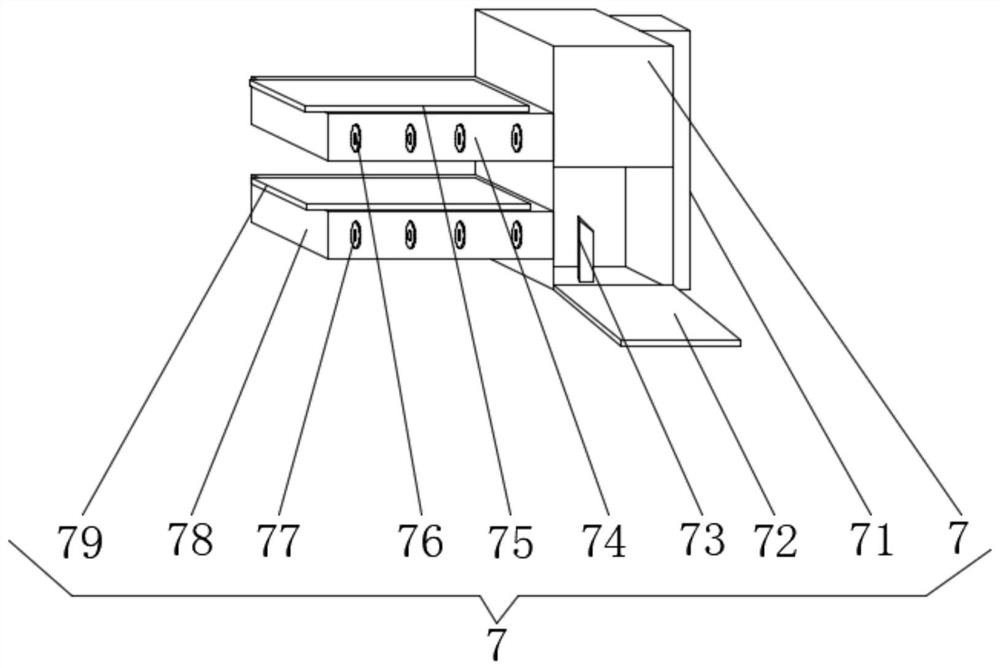

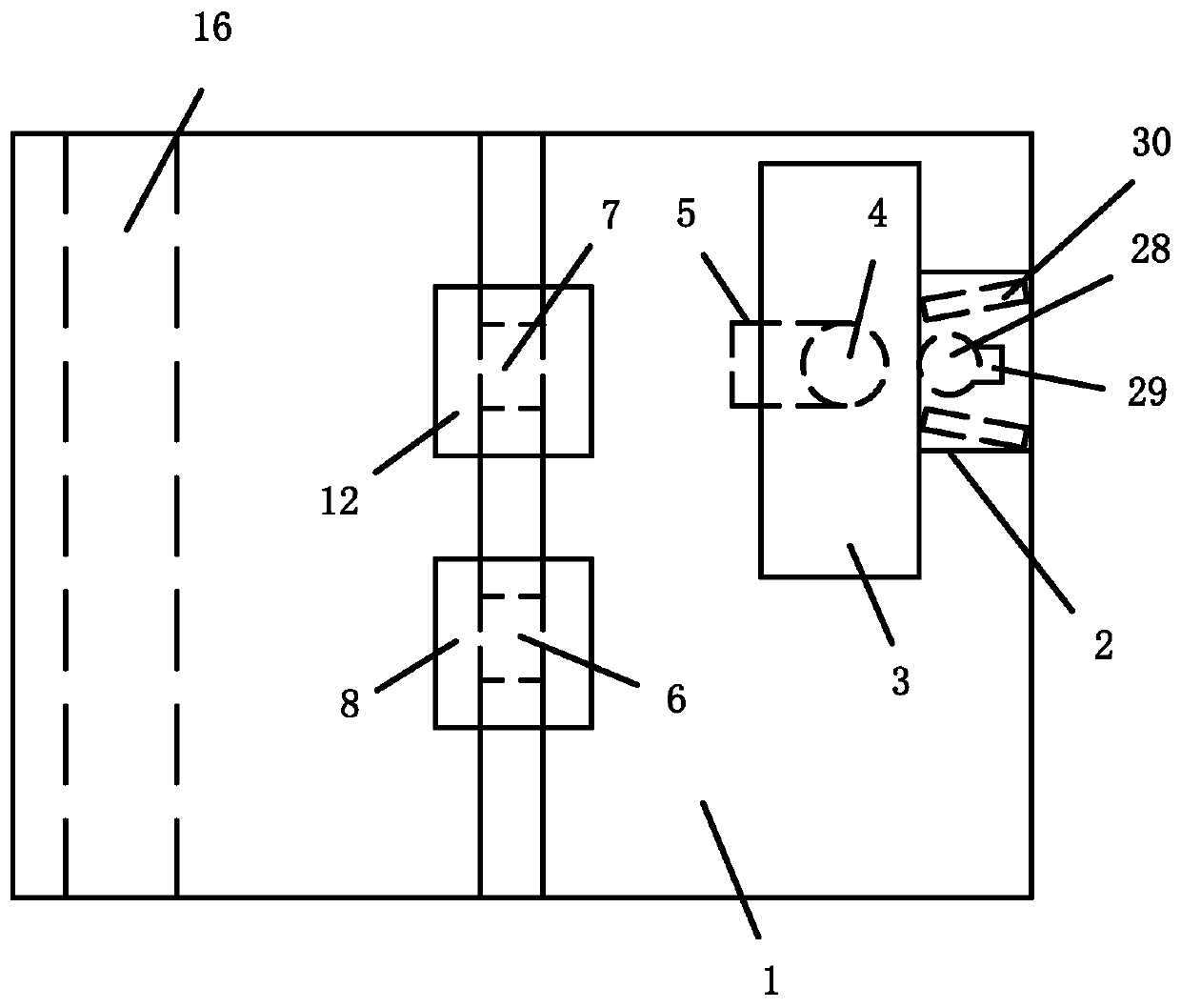

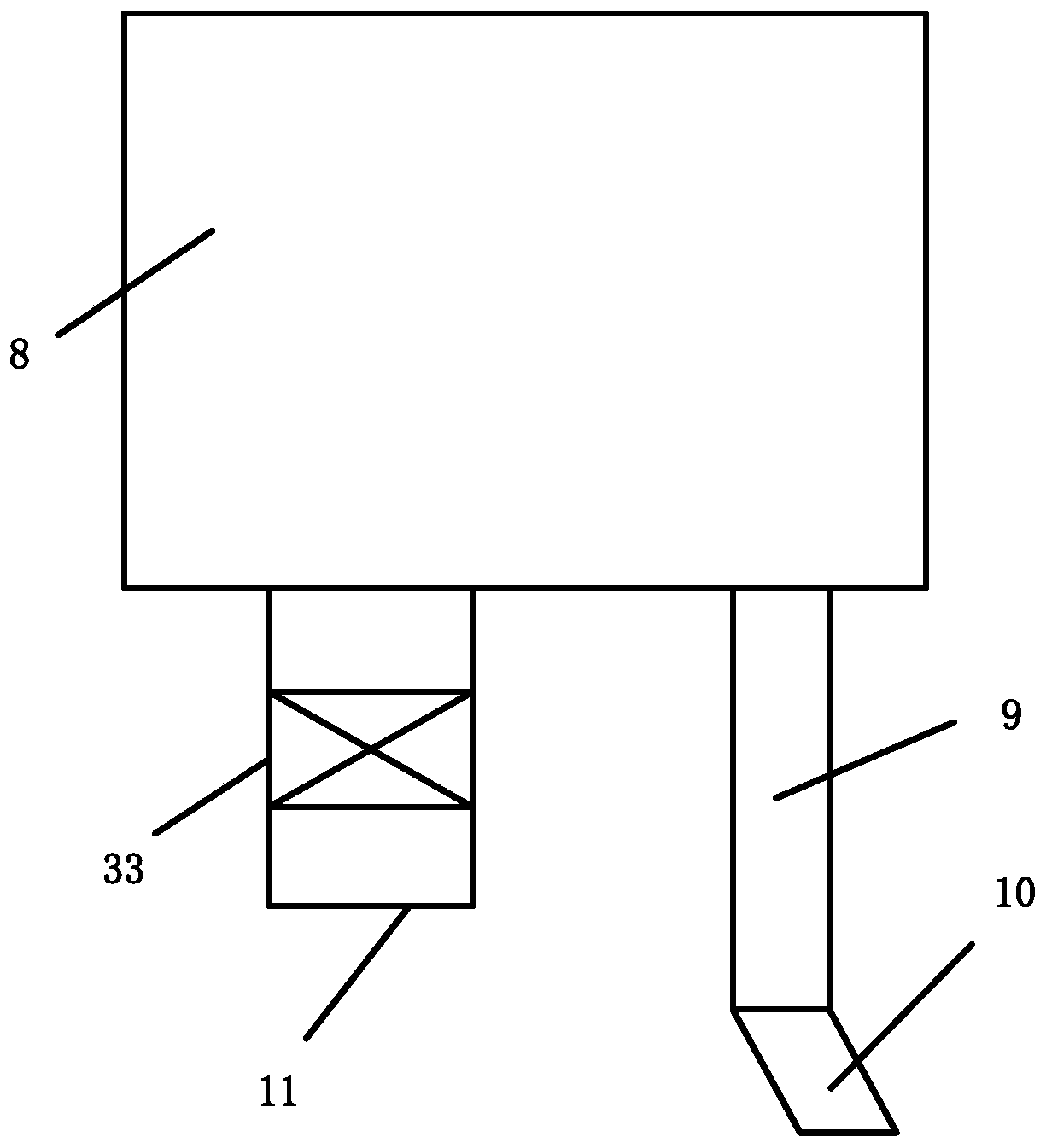

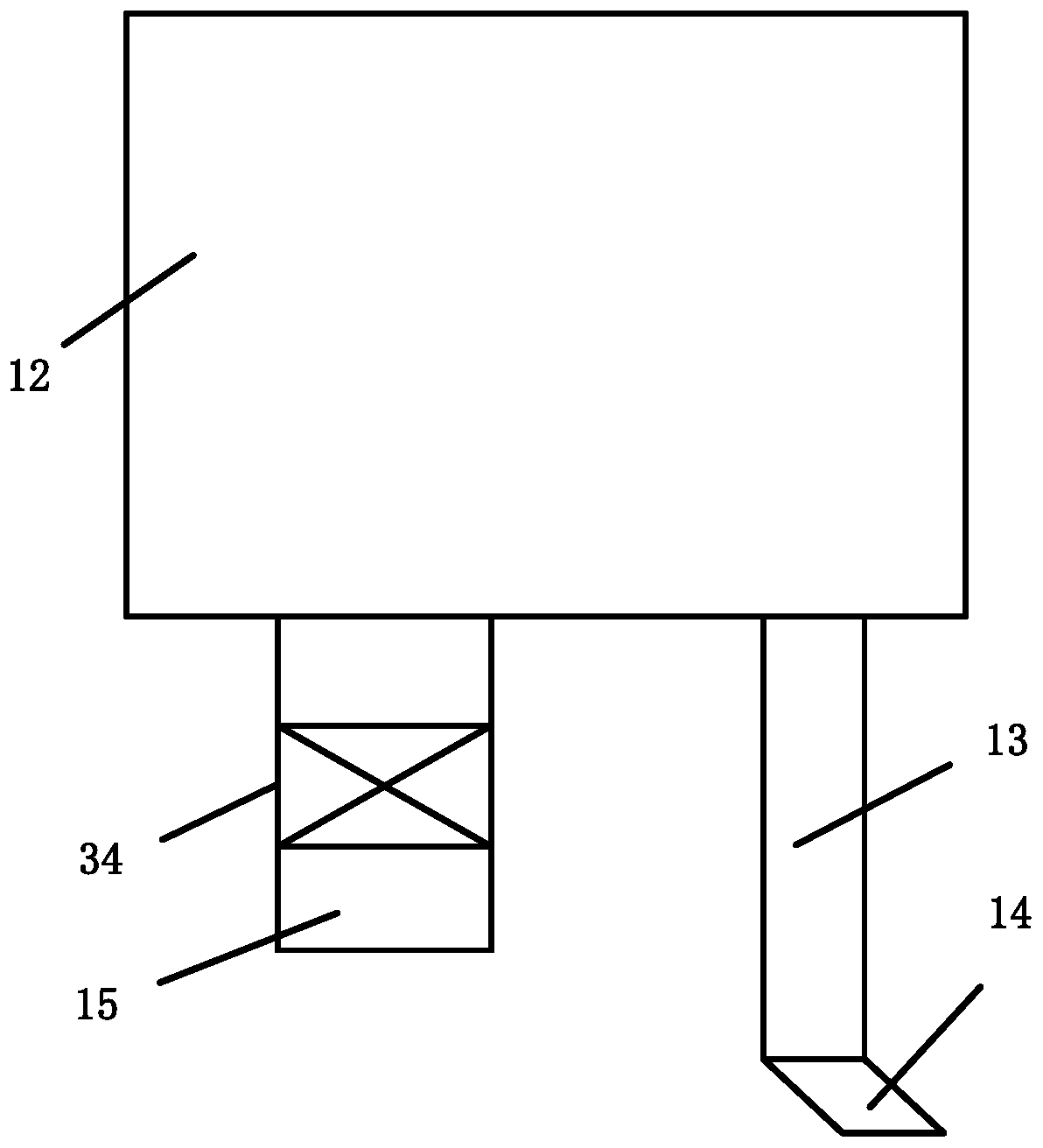

Horizontal rotary position changer

InactiveCN109262188ASimple structureCompact structureWelding/cutting auxillary devicesAuxillary welding devicesReducerAerospace engineering

The invention discloses a horizontal rotary position changer. The horizontal rotary position changer is characterized by comprising a bottom box (1), a hollow speed reducer (2) is arranged above the bottom box (1), a shell of the hollow speed reducer (2) is fixedly connected with the bottom of the center position of a rotary box (3), and a rotary motor is arranged in the rotary box (3); an operating end of the rotary motor is connected with an input end of the hollow speed reducer (2), an output end of the hollow speed reducer (2) is fixed to the bottom box (1), and a gap is reserved between the shell of the hollow speed reducer (2) and the bottom box (1); the upper portion of the rotary box (3) is provided with an openable dodge gate (4) above a cavity in which the rotary motor is positioned.

Owner:大连河野智能装备有限公司

A convenient on-board charging system for new energy vehicles

InactiveCN108282006BExtended charging rangeReduce the chance of entanglementBatteries circuit arrangementsElectric powerIn vehicleNew energy

The invention relates to a convenient on-board charging system for new energy vehicles, comprising a first housing, a second housing, a USB interface, a wire take-up mechanism and a dust-proof mechanism. The wire take-up mechanism includes a power supply assembly, a guide rail, a screw rod, a rotating Shaft, first sliding block, guide ring, second sliding block, charging cable, transmission assembly, brake assembly, two turntables and two telescopic ropes, dustproof assembly includes drive assembly, first connecting rod, second connecting rod And dust cover, this is used in the convenient on-board charging system of new energy vehicles, the charging range of the charging system is not only expanded through the wire take-up mechanism, but also the charging wires can be stored in the charging system in an orderly manner, reducing the The probability of the charging wires being entangled improves the practicability of the charging system. The dust-proof mechanism not only reduces the amount of dust entering the USB interface, but also reduces the probability of damage to the USB interface during the use of the charging system. , improve the practicality of the charging system.

Owner:国网甘肃省电力公司酒泉供电公司

An intelligent manufacturing equipment for knitted garments

ActiveCN109355818BEasy to installEasy to disassembleWork-collecting devicesThread-laying mechanismsPlastic packagingSmart manufacturing

The invention discloses an intelligent manufacturing device for knitted clothing. The intelligent manufacturing device comprises an intelligent manufacturing device body, an installation stand is fixedly installed on the outer surface in the middle at the upper end of the intelligent manufacturing device body, a transverse shaft is fixedly installed on the outer surface in the middle at the frontend of the installation stand, a machine box is fixedly installed on the outer surface at the front end of the transverse shaft, and the transverse shaft is fixedly connected to the outer surface at the upper end of the machine box. A thread separating mechanism is fixedly connected to the outer surface on one side of the installation stand, and a fixing plate is fixedly installed on the outer surface at the lower end of the intelligent manufacturing device body. Through an installation and disassembly mechanism, needles on the machine can be installed and disassembled, and it is convenient for people to use the device; through the thread separating mechanism, connecting threads can be separated and isolated, the connecting threads are prevented from being twined in the machine, the woundthread can be disposed in time, and more convenience is brought to use of people; through a plastic packaging mechanism, the manufactured clothing can be packaged, the situation that the clothing is placed at random, and consequently, the clothing is damaged is prevented, and using of people is facilitated.

Owner:嘉兴羽希服饰有限公司

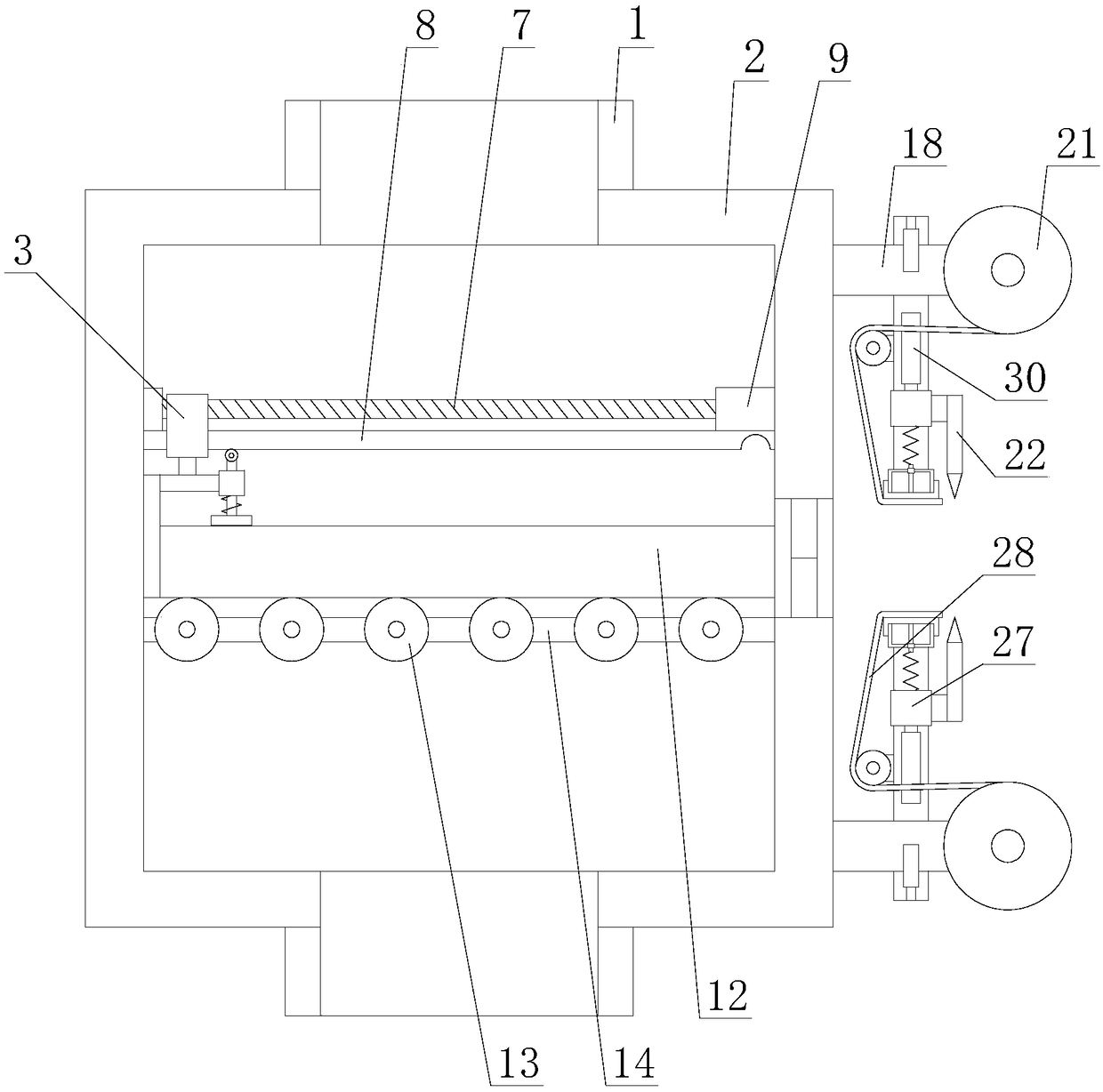

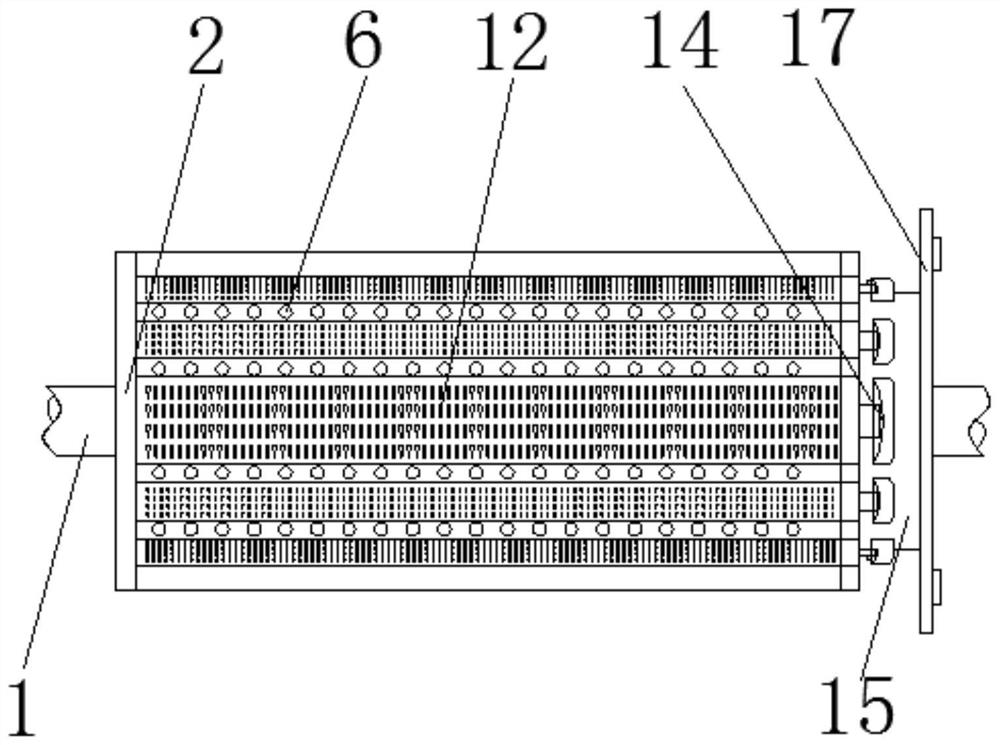

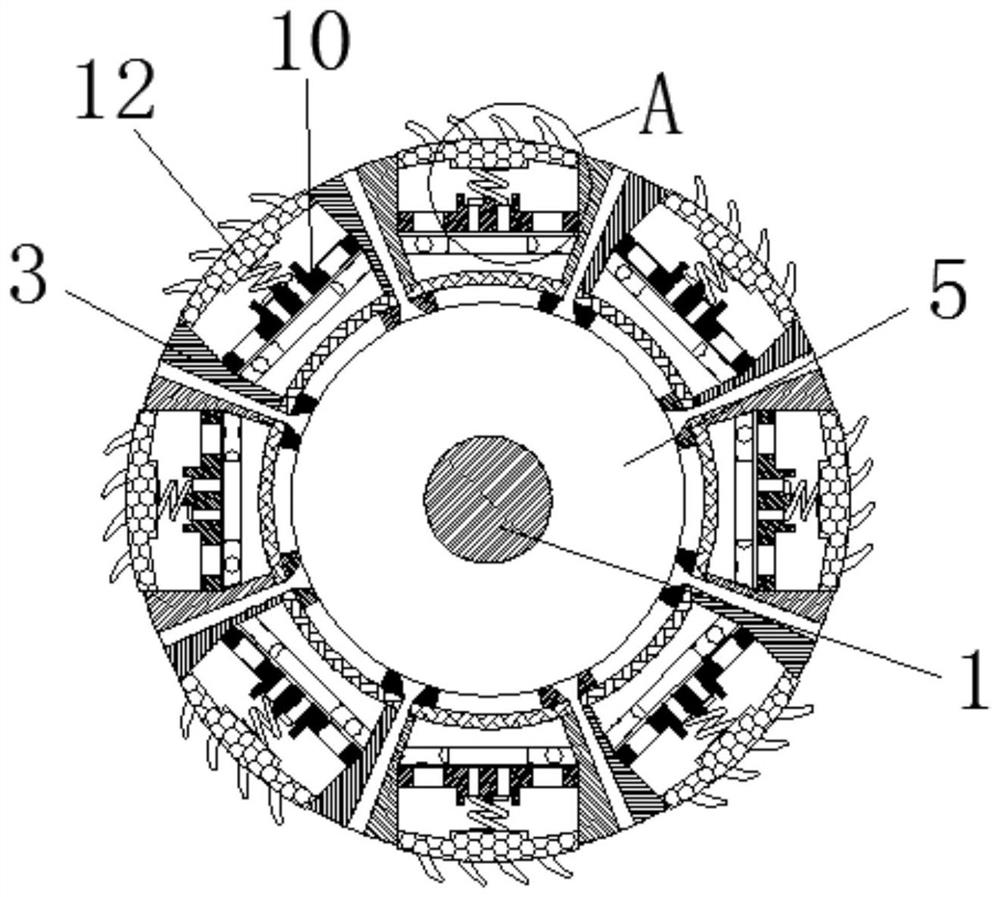

An energy-saving and environment-friendly vacuum dust removal carding machine cylinder device

InactiveCN112144151BReduce breakupReduce the chance of entanglementCarding machinesDust controlEngineering

The invention relates to the technical field of textile equipment, and discloses an energy-saving and environment-friendly vacuum dust removal carding machine cylinder device, which includes a main shaft, end plates are arranged at both ends of the main shaft, and a barrel bracket is fixedly connected to the middle of the two end plates. The inner surface of the bracket is provided with a support cylinder, and the inside of the support cylinder is provided with a vacuum chamber. Several rows of adsorption passages are arranged in the radial direction of the cylinder holder, and installation grooves are arranged between two adjacent rows of the adsorption passages. The bottom of the installation grooves is provided with The protection screen is provided with a baffle on the outside of the protection screen along the radial direction. The energy-saving and environment-friendly vacuum dust removal carding machine cylinder device, by setting a vacuum chamber inside the support cylinder, the right end of the external connection pipe is connected with the exhaust fan filter and the dust treatment device, and compresses the exhaust and dust removal mechanism originally placed outside the cylinder. Entering into the cylinder not only compresses the volume of the carding machine, but also makes the cotton web close to the cylinder when the carding machine is working, reducing the chance of the cotton web being broken up and entangled by the cylinder in high-speed mode.

Owner:简胜坚 +2

Safe and energy-saving propeller

The invention discloses a safe and energy-saving type propeller. The safe and energy-saving type propeller comprises a propeller hub serving as an inner ring and a protective ring serving as an outerring. The propeller hub and the protective ring are arranged coaxially. Three sets of propeller blades are evenly distributed between the propeller hub and the protective ring. Each propeller blade isof an arc-shaped curved surface structure, wherein a certain inclination angle is formed between the arc-shaped curved surface structure and the movement direction of the propeller. Blade roots of the propeller blades are connected with the propeller hub. Blade tips of the propeller blades are connected with the inner side surface of the protective ring. The protective ring is of an arc-shaped symmetrical round ring structure with the middle being concave inwards. The axial length of the propeller hub is larger than that of the protective ring. The front end face of the protective ring is arranged between the front end face and the rear end face of the propeller hub. The rear end face of the propeller hub is arranged between the front end face and the rear end face of the protective ring.Each set of propeller blades comprises a main blade and an auxiliary blade which are arranged uniformly. The front section part of each main blade is a bending part which bends towards the rotating direction of the propeller blades. The front end part of each auxiliary blade is an arc-shaped concave part being concave backwards. The safe and energy-saving type propeller is simple in structure, high in safety and good in energy saving performance.

Owner:成都市陈式船舶研发有限公司

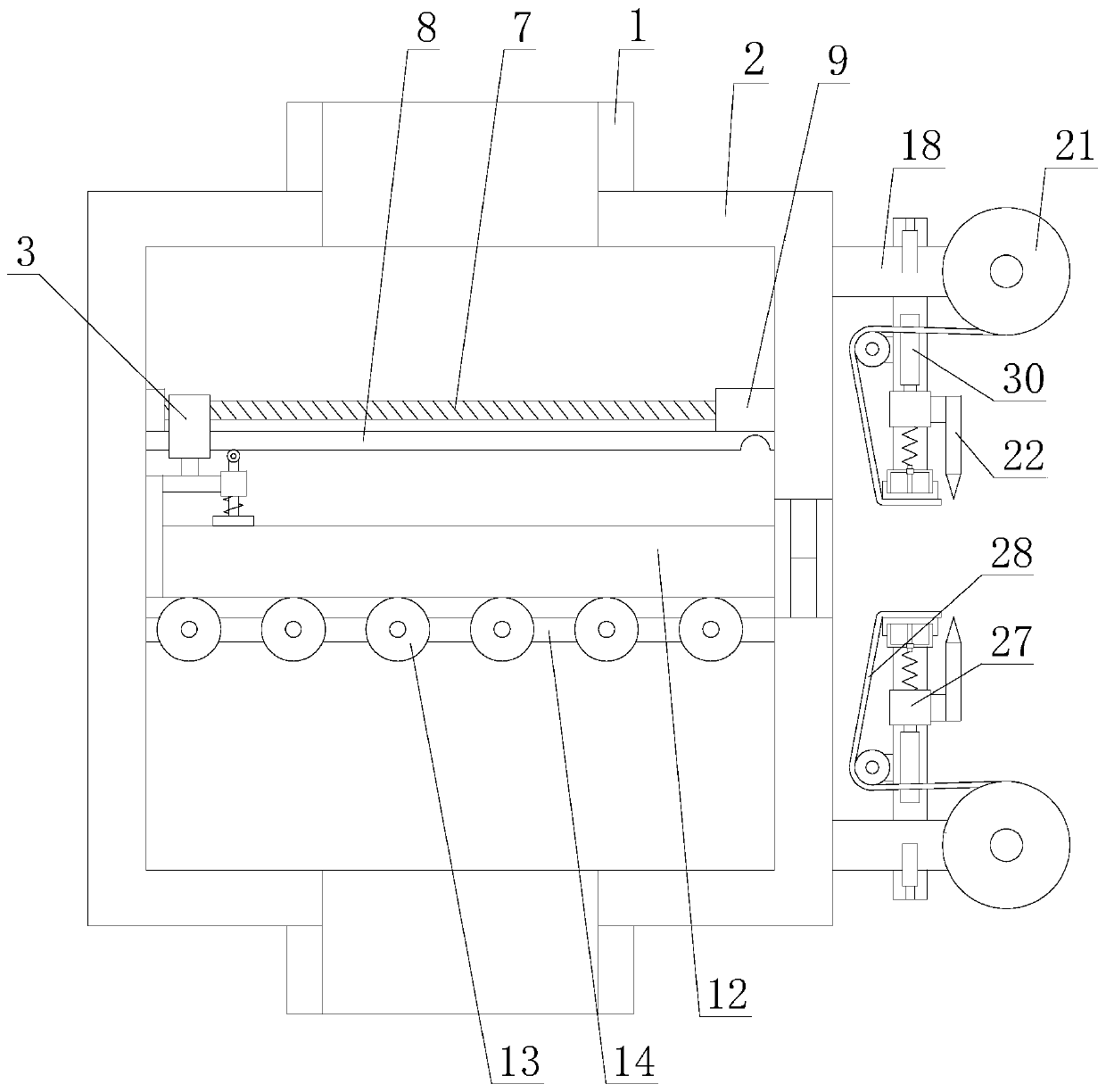

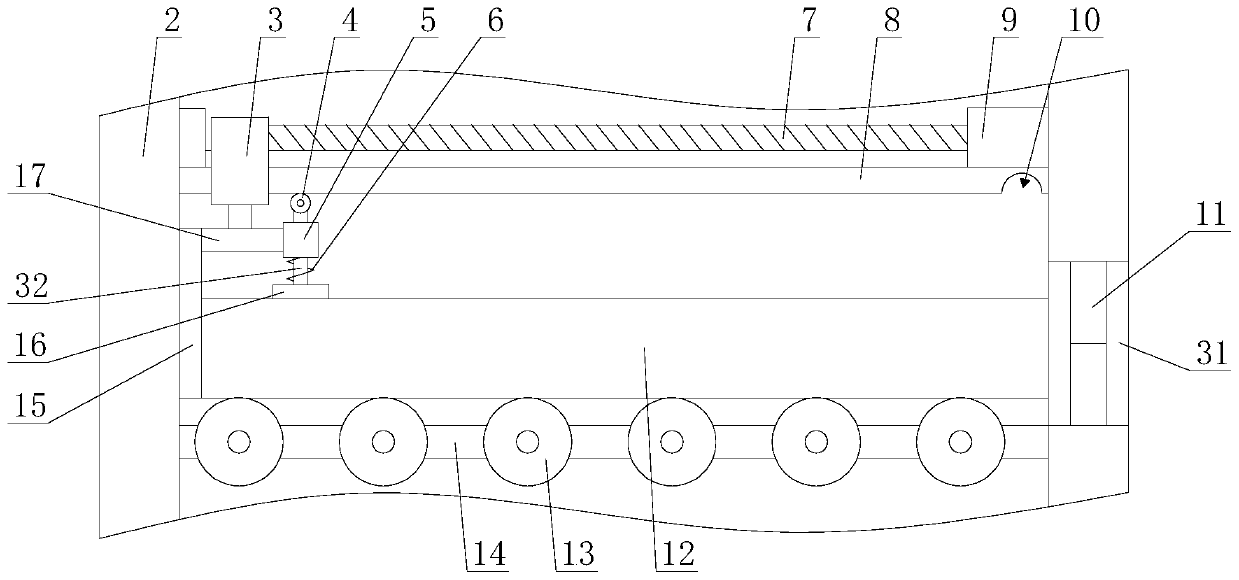

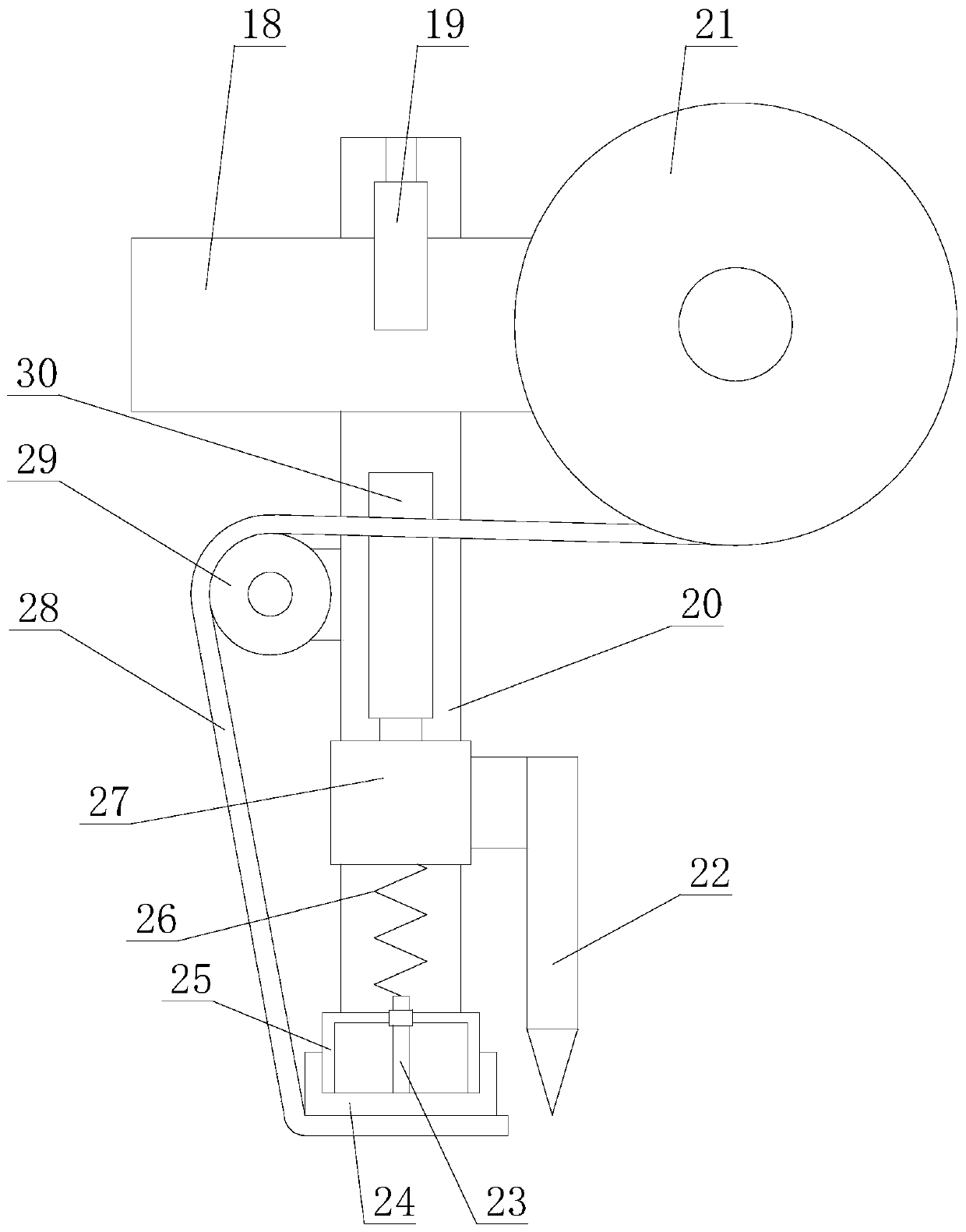

Organic and inorganic fertilizer same-machine different-position precision sowing machine for corn

The invention discloses an organic and inorganic fertilizer same-machine different-position precision sowing machine for corn. The organic and inorganic fertilizer same-machine different-position precision sowing machine comprises a rack, a furrow opener is arranged on the rack, a sowing box is fixed to the rear side of the furrow opener, a sowing pipe is connected to the bottom of the sowing box, and a slant pipe is arranged at the tail end of the sowing pipe; a first slide block and a second slide block are transversely and slidably installed on the rack, an organic fertilizer tank is fixed to the first slide block, the bottom of the organic fertilizer tank is connected with a first shovel blade through a first hydraulic oil cylinder, a first discharging pipe is connected to the bottom of the organic fertilizer tank, a first adjusting valve is installed in the first discharging pipe, and the first discharging pipe is located at the rear side of the first shovel blade; an inorganic fertilizer tank is fixed to the second slide block, the bottom of the inorganic fertilizer tank is connected with a second shovel blade through a second hydraulic oil cylinder, a second discharging pipe is connected to the bottom of the inorganic fertilizer tank, a second adjusting valve is installed in the second discharging pipe, and the second discharging pipe is located at the rear side of the second shovel blade. By means of the organic and inorganic fertilizer same-machine different-position precision sowing machine, the defects of the prior art can be overcome, and synchronous and precise application of different types of fertilizers is achieved.

Owner:HEBEI AGRICULTURAL UNIV.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com