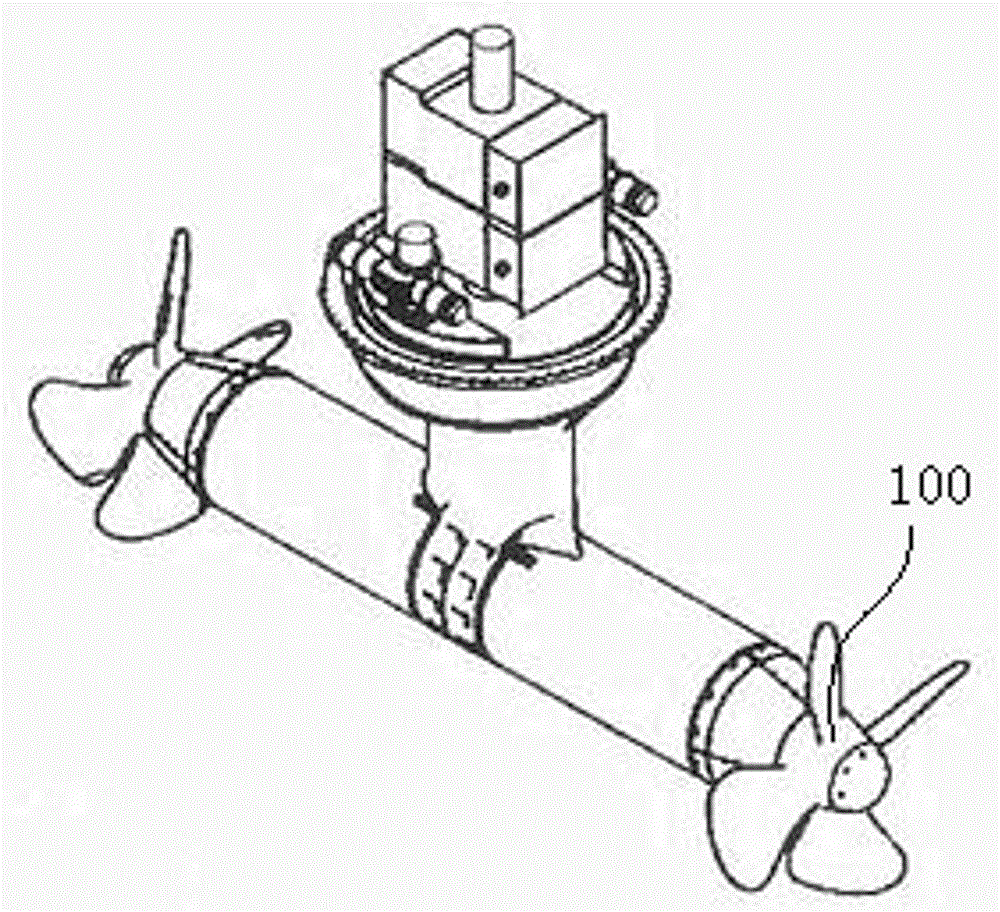

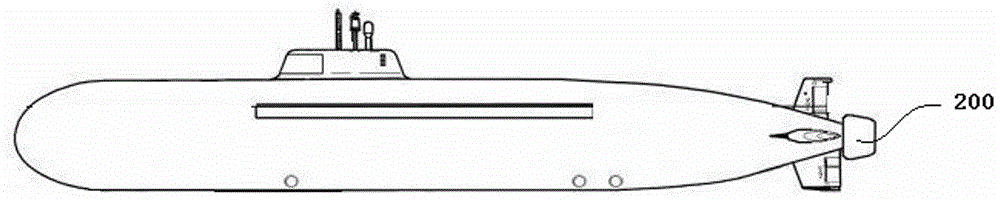

Pipeline thruster with protection function

A technology of protection function and propulsion, applied in the direction of rotary propulsion, ship propulsion, propulsion components, etc., can solve the problems of easy entanglement of foreign objects, complex structure, high motor speed, reduce the probability of foreign objects entanglement, simplify equipment structure, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

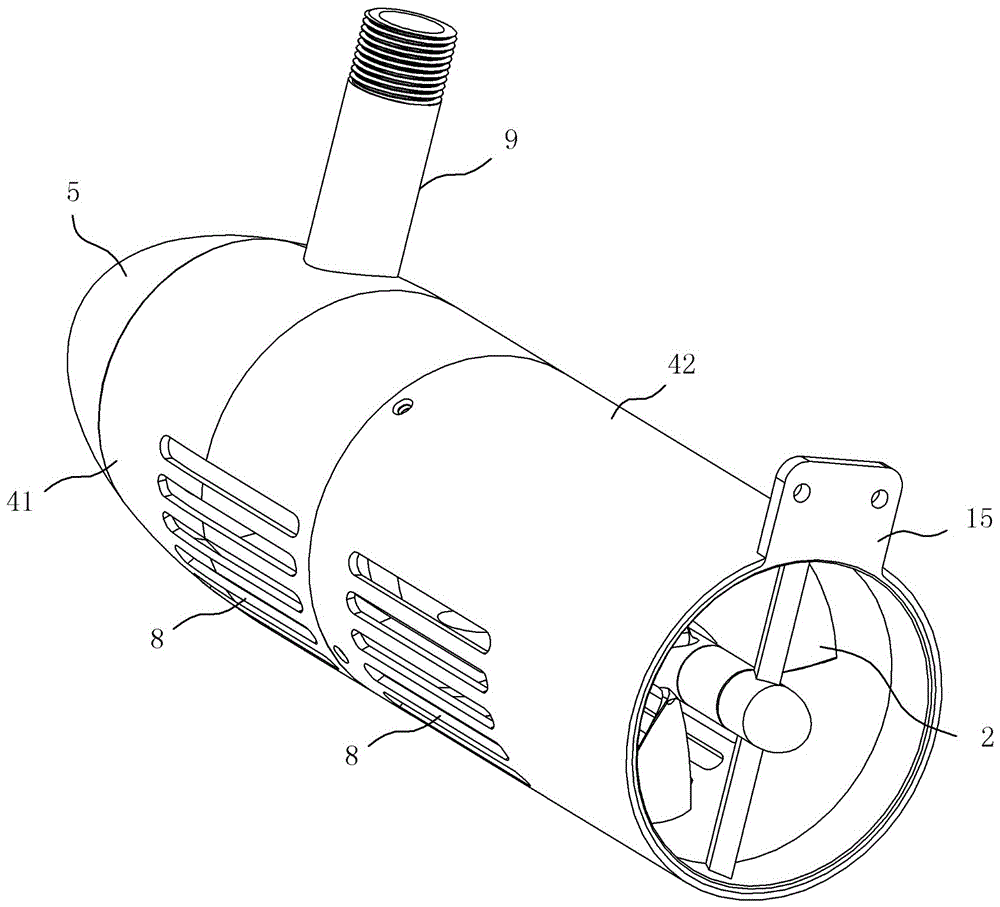

[0012] Such as Figure 3-6 shown.

[0013] A pipeline propeller with a protective function, including a driving motor 1, a propeller 2, a rotating shaft 3 connecting the driving motor and the propeller, and a cylindrical guide tube 4; one end of the guide tube is installed with a rectifier that seals the end Cover 5, drive motor is installed in one end close to the fairing in the flow guide tube, propeller is installed in the other end in the flow guide tube, also is installed in the flow guide tube with the motor case 6 that will drive motor be wrapped in it, the motor case The inner wall is close to the outer wall of the drive motor, and the end of the motor housing close to the fairing is sealed; there is a shaft housing 7 covering part of the rotating shaft, and the two ends of the shaft housing are respectively connected to the end of the motor housing away from the fairing, and The middle part of the rotating shaft is sealed and connected; the guide tube is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com