Novel combined harvester shredding device

A technology of shredding device and harvester, applied in the direction of harvester, cutter, etc., can solve the problems of large handover distance of fixed knives, small diameter of rotating cylinder, large number of fixed knives, etc. Low power, good weeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

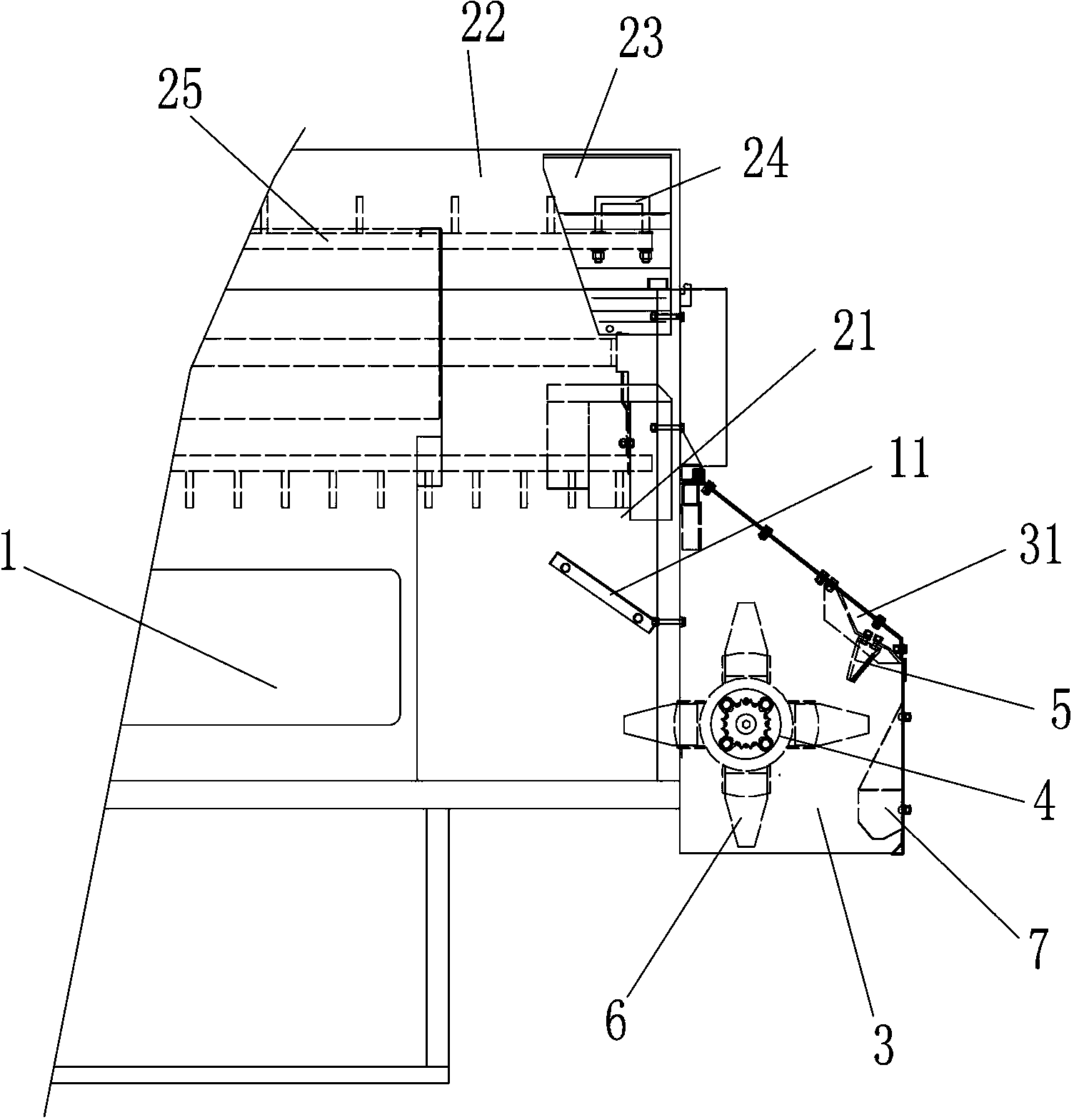

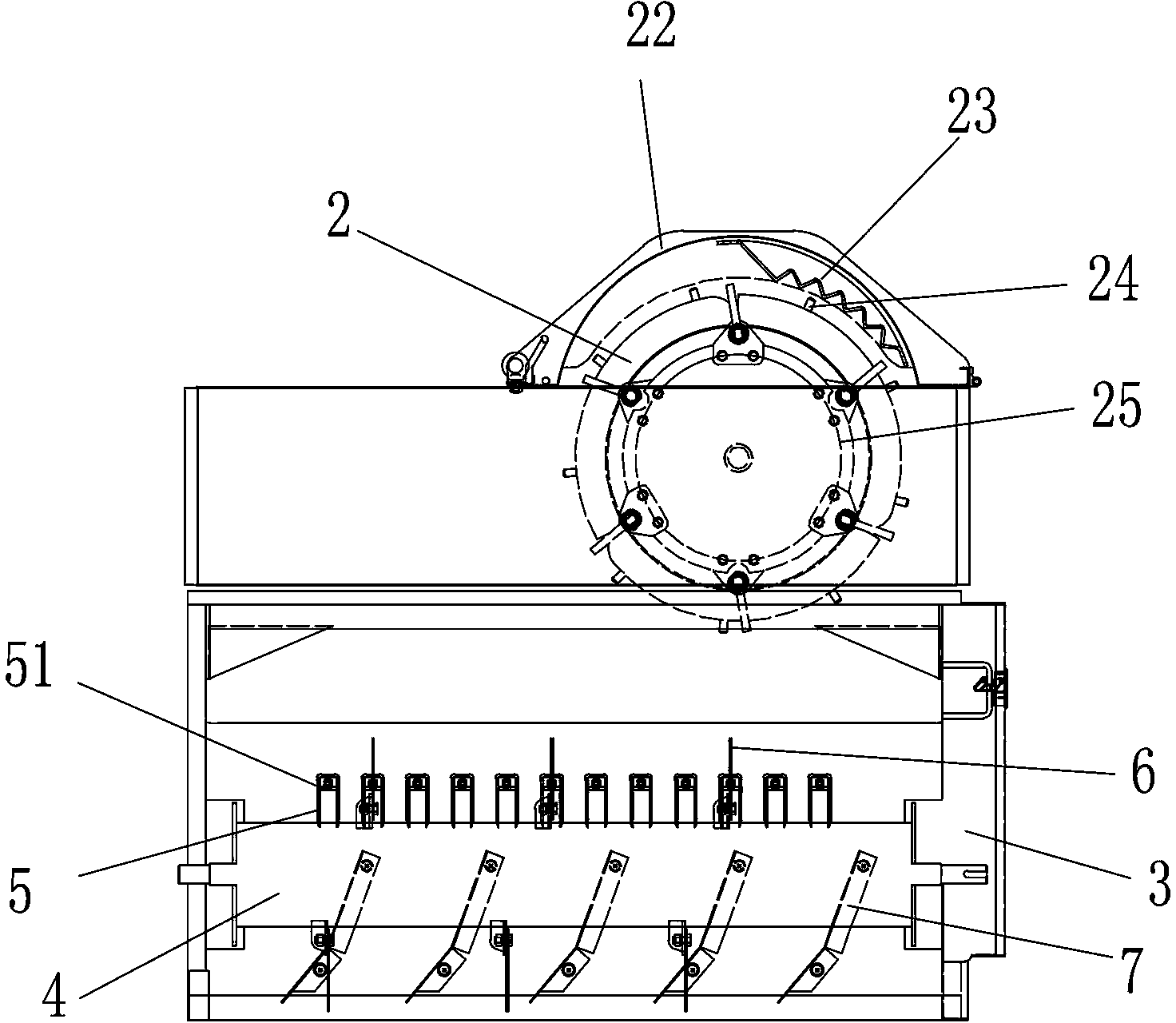

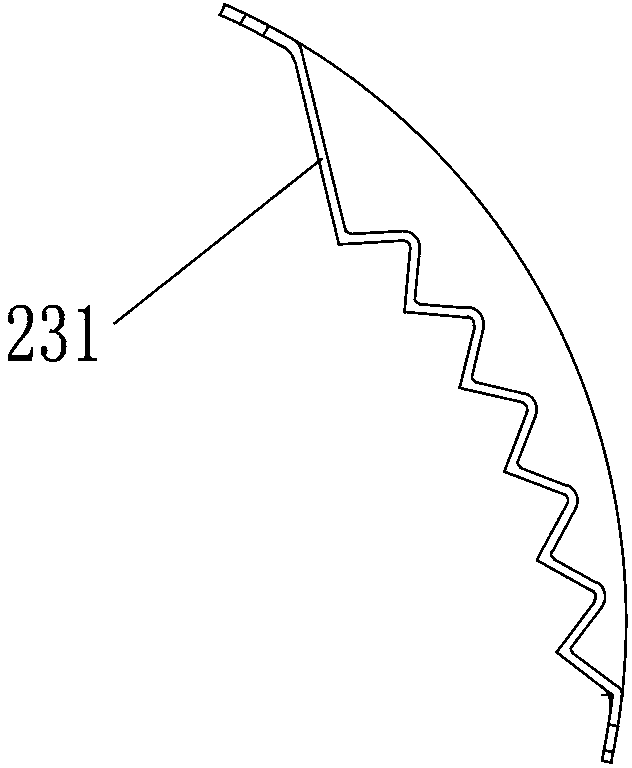

[0039] A new combined harvester chopping device, the harvester includes a frame 1 and a threshing drum 2 arranged on the top of the frame 1, the threshing drum 2 includes a top cover 22 and a rack 25, the threshing drum 2 The bottom of the end is provided with a discharge port 21, and the chopping device includes a broken grass washboard 23 arranged at the rear end of the top cover 22, a tooth 24 arranged on the rack 25 and matched with the broken grass washboard 23, and a tooth 24 arranged at the discharge port 21. The grass cutter assembly below, the grass cutter assembly includes a discharge rack 3 arranged at the rear end of the frame 1, a frame cover 31 arranged on the discharge frame 3, a discharge chamber positioned under the frame cover 31, The discharge drum 4 arranged on the discharge rack 3 and located in the discharge chamber, the fixed knife 5 and the movable knife 6 arranged on the discharge rack 3 and the discharge drum 4, the discharge port 21 and the discharge ...

Embodiment 2

[0045] The difference from the above implementation is that there are 15 fixed knives, and 5 rows of movable knives are evenly distributed on the surface of the discharge drum, and each row has 3 movable knives, and the movable knives on adjacent rows are arranged alternately. The handover distance between the moving knife and the fixed knife is 20mm, and the diameter of the discharge drum is 160mm.

Embodiment 3

[0047] The difference from the above implementation is that there are 10 fixed knives, and 5 rows of movable knives evenly distributed on the surface of the discharge drum, with 2 movable knives in each row, and the movable knives on adjacent rows are arranged alternately. The handover distance between the moving knife and the fixed knife is 30mm, and the diameter of the discharge drum is 180mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com