Gas-phase-space-free oil tank

A gas-phase space and fuel tank technology, applied in the field of gas-free space fuel tanks, can solve problems such as difficult implementation, not simple structure, oil vapor leakage, etc., and achieve the effects of protecting life and property, simple structure and easy implementation, and avoiding volatilization loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

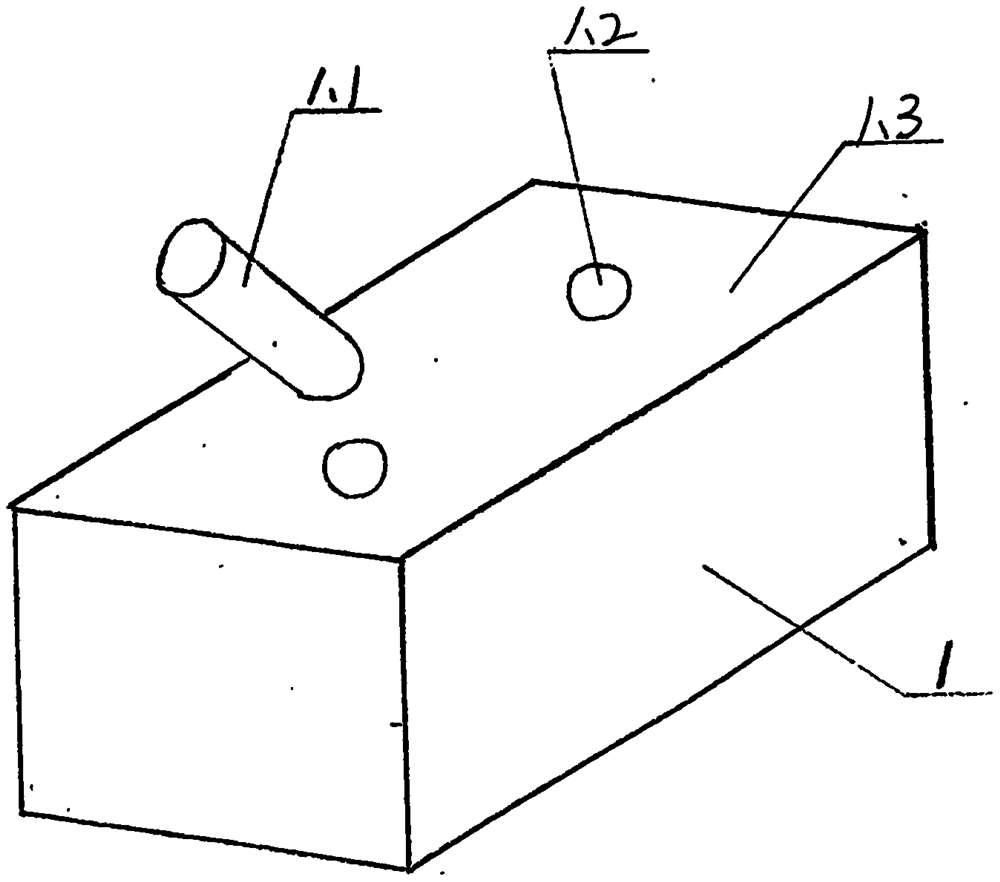

[0017] figure 1 As shown, the top plate 1.3 of the oil tank body 1 is equipped with an assembly port 1.2 and a refueling caliber 1.1.

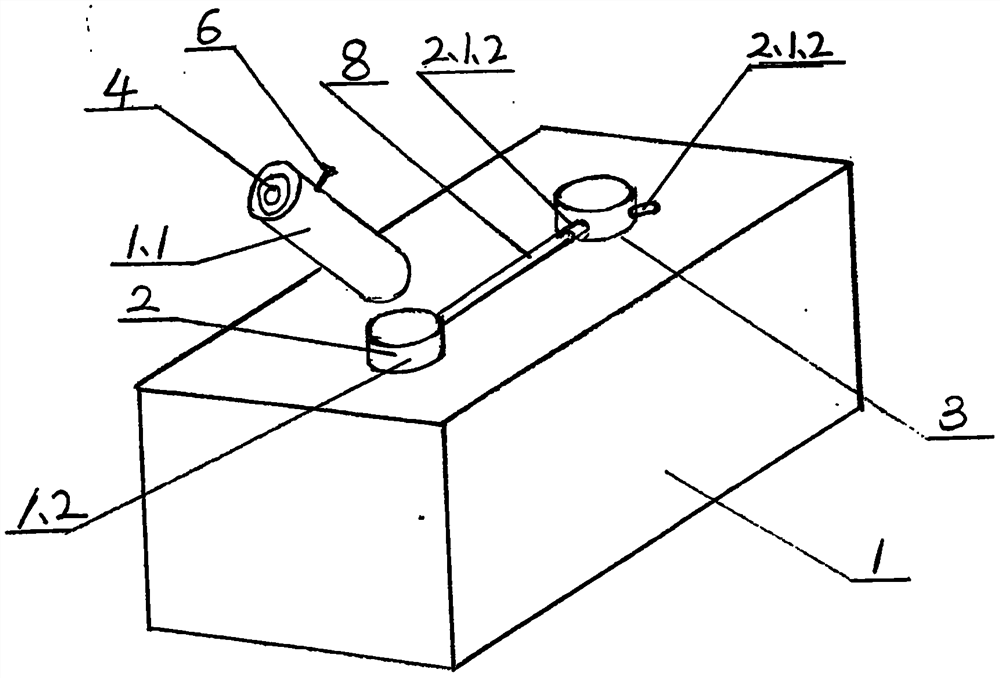

[0018] figure 2As shown, the top of the box body 2.1 is provided with a threaded hole 2.1.1, the side wall is provided with an interface 2.1.2, the center of the bottom is provided with a round mouth 2.1.3, and the periphery of the round mouth 2.13 is provided with a threaded hole 2.1.2, and the box cover 2.2 There are round holes 2.2.1, the bottom surface is formed with annular bosses 2.2.2, the center of the connecting piece 2.3 is made with sockets 2.3.1, the periphery is arranged with round holes 2.3.2, and the bottom surface is made with bosses 2.3.3; O The shape ring 2.4 is placed on the annular boss 2.2.2 and the boss 2.3.3 respectively, and the screw 2.5 seals and fixes the box cover 2.2 and the connecting piece 2.3 to the top of the box body 2.1 and the bottom of the box body 2.1 respectively.

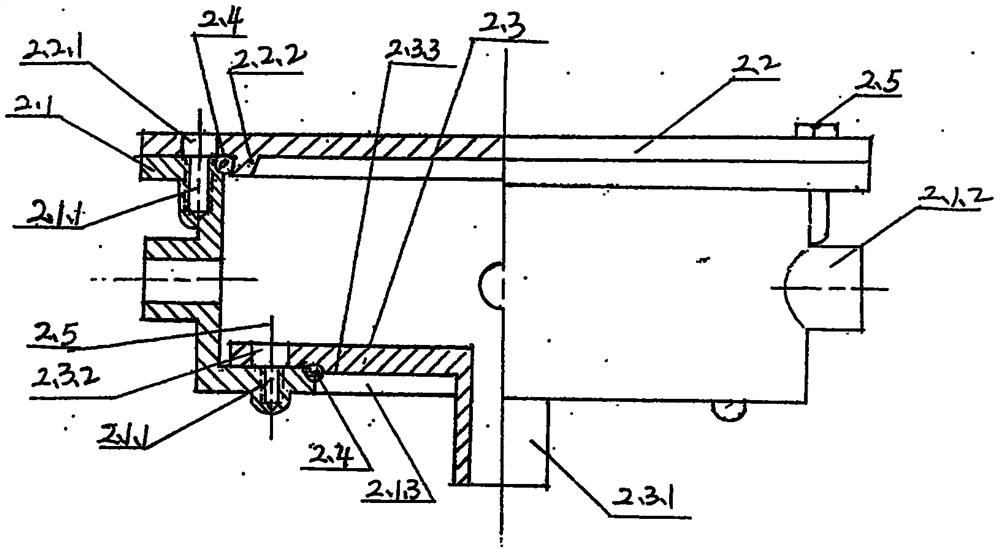

[0019] image 3 As shown, the capsu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com