Knotting-prevention dyeing equipment for wig

A kind of dyeing equipment and wig technology, applied in the field of wig dyeing, can solve the problems of soft hair, wig knotting and falling off, uneven dyeing, etc., and achieve the effect of uniform dye mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

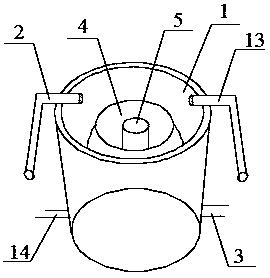

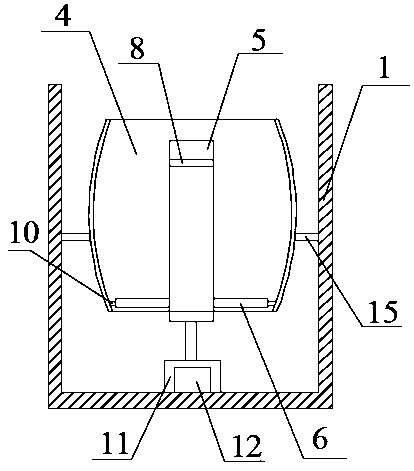

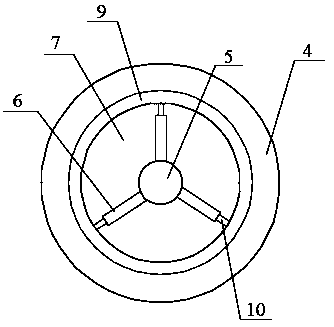

[0024] An anti-tangle wig dyeing device, comprising a dye bucket 1, a heating wire is arranged in the inner cavity of the side wall of the dye bucket 1, so that the dye in the dye bucket 1 maintains a certain temperature, and the side wall of the dye bucket 1 A dye inlet 2 is arranged on the top of the dye barrel, a dye outlet 3 is arranged on the side wall at the bottom of the dye barrel 1, a switching valve is arranged at the dye outlet 3, an anti-knot mechanism is arranged in the dye barrel 1, and the anti-knot mechanism It includes a placement cylinder 4 for accommodating wigs, and the two sides of the placement cylinder 4 are suspended and arranged in the dye barrel 1 through a fixing rod 15 . The placement cylinder 4 is a shell with openings at the upper and lower ends, and the body of the placement cylinder 4 is in the shape of a drum. The outlet at the bottom of the placement cylinder is divergent outward, so that the top diameter of the outlet at the bottom of the pla...

Embodiment 2

[0030] One end of the side wall of the dye bucket 1 is also provided with a water inlet 13, and the other end of the side wall of the dye bucket 1 is provided with a water outlet 14, and the water outlet 14 is provided with a switch valve, and a fan is also provided in the placement box 11 , the side wall of the main shaft of the rotating motor is a cavity structure, and the outlet end of the fan passes through the side wall of the main shaft of the rotating motor through an air outlet duct and is connected with an air intake pipe arranged in the inner cavity of the support column 5, and the air intake pipe Through several branch pipes, it communicates with the inner cavity of the connecting rod 6, and the 6 side walls of the connecting rod are provided with several air outlets, and the air outlets communicate with the branch pipes through the air outlet pipes communicated with it, and each connecting rod 6 The air outlets on the top are all located on the same side of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com