Safe and energy-saving propeller

An energy-saving, propeller technology, applied in the direction of rotating propellers, rotary propellers, ship construction, etc., can solve the problems of high linear velocity of the propeller tip, scratch of the propeller tip, and reduce the efficiency of the propeller, so as to increase the reaction thrust section and stabilize the Good performance and wide range of speed adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

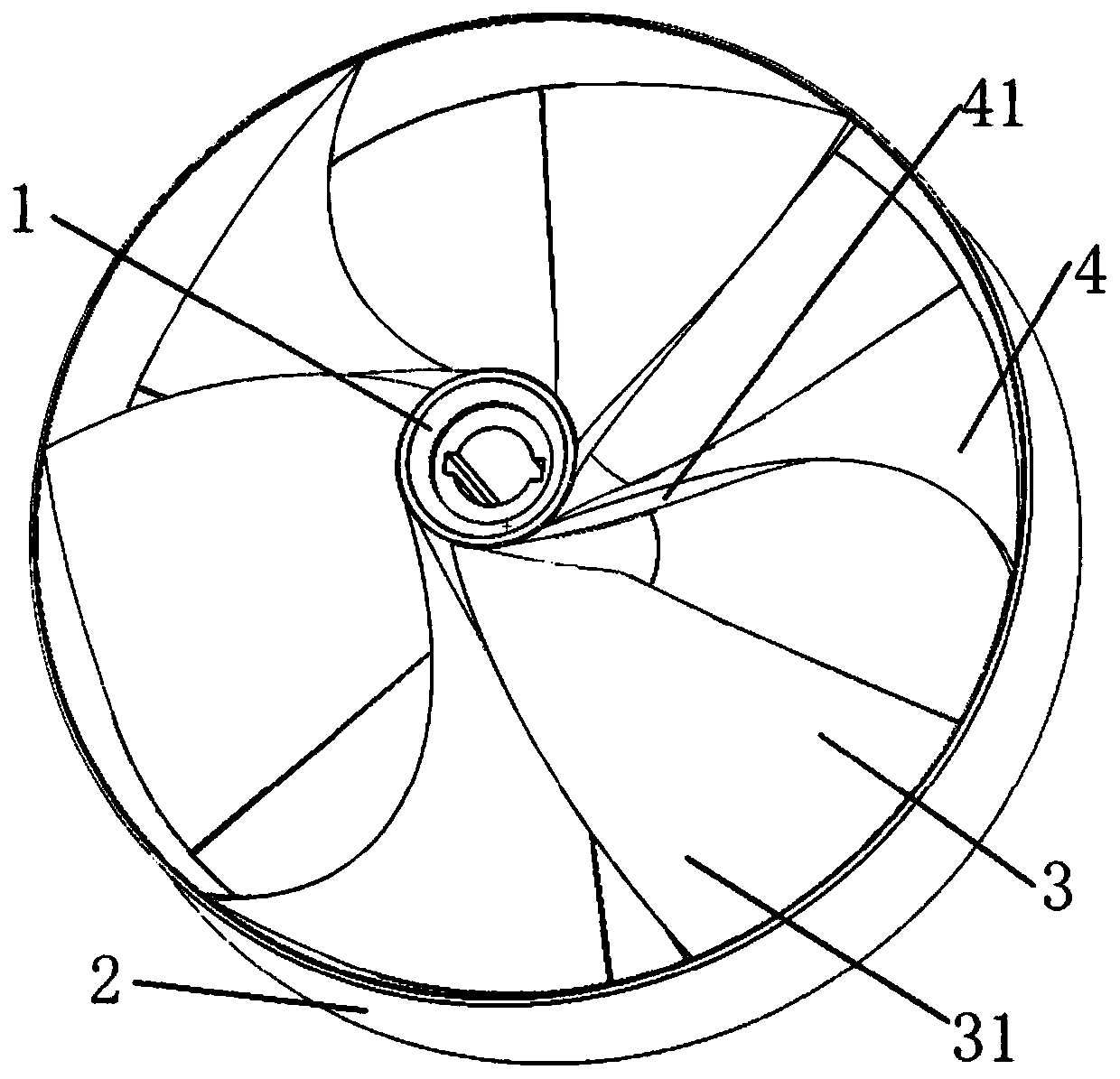

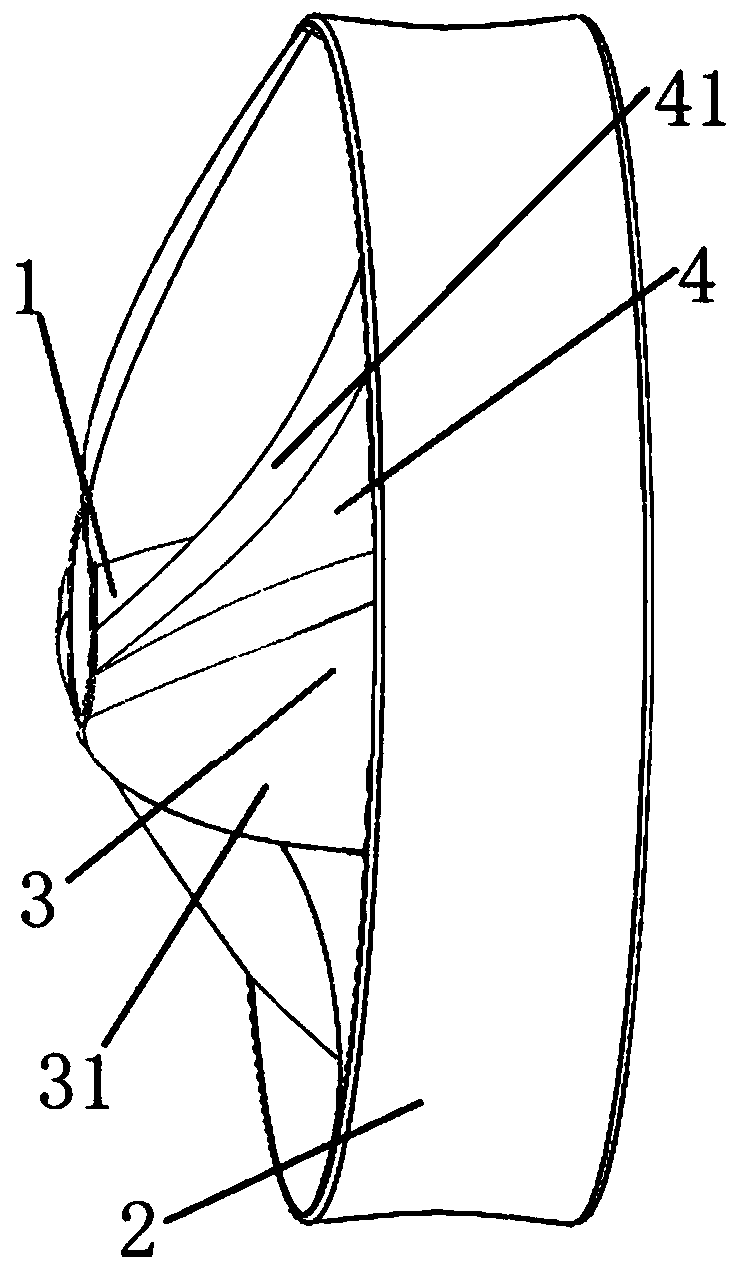

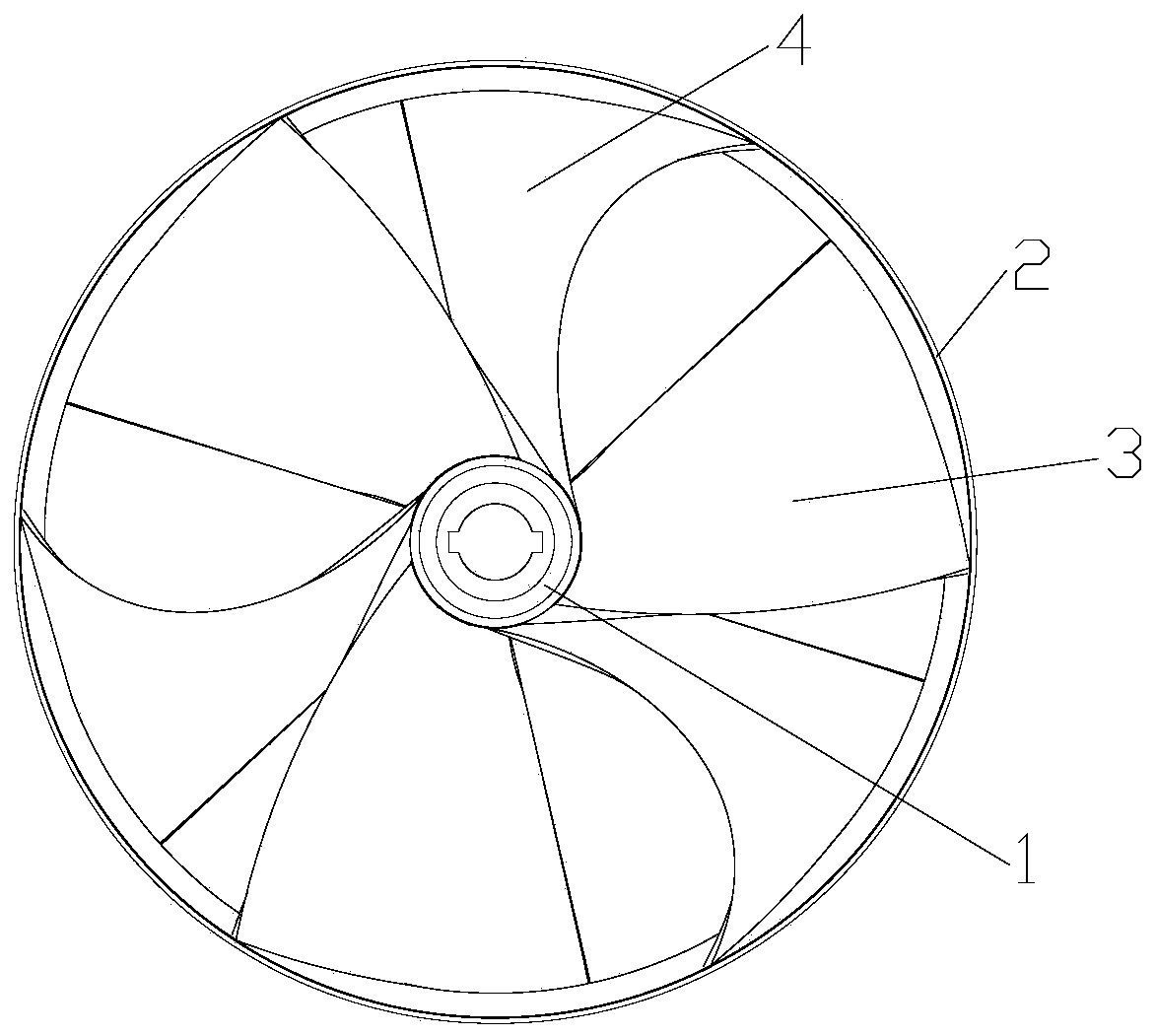

[0046] like Figure 1-4 As shown, a safe and energy-saving propeller includes a hub 1 as the inner ring and a protection ring 2 as the outer ring. The hub 1 and the protection ring 2 are coaxially arranged, and the space between the hub 1 and the protection ring 2 is uniform The paddle is provided with a blade, and the blade is an arc-shaped surface structure, and the blade is at a certain angle of inclination with the direction of motion of the propeller that is consistent with the motion direction of the ship; the blade root of the blade is connected to the hub 1, The tip of the blade is connected to the inner surface of the protection ring 2; the protection ring 2 is an arc-shaped symmetrical ring structure with the middle part concave inward;

[0047] The axial length of the propeller hub 1 is greater than the axial length of the protective ring 2, the front end surface of the protective ring 2 is arranged between the front end surface and the rear end surface of the prope...

example 2

[0057] This propeller will not cause fatal harm to people working and swimming underwater, and the cutting damage to various underwater fish and aquatic organisms will also be greatly reduced. Compared with conventional propellers, the probability of being entangled by aquatic plants and debris will also be reduced. a lot of. (Example 1: At 6:00 p.m. on September 10, 2016, Comrade Cao Moumou, deputy secretary of the Yanjiang District Committee of Ziyang City, Sichuan Province, was injured and killed by a conventional propeller blade of a high-speed speedboat while swimming underwater. Example 2: During the test period, Chen himself accidentally fell into the water and came into contact with the outer ring of the propeller with a speed of about 320 revolutions per minute. He felt that the propeller was lubricated in the water and did not cause any harm to the human body).

[0058] 2. Energy saving and environmental protection

[0059] 1. The blade is an arc-shaped surface stru...

Embodiment 2

[0074] This embodiment is a further improvement on the basis of Embodiment 1. The difference from Embodiment 1 is that each group of blades includes 2 auxiliary blades, and the two auxiliary blades are respectively arranged on the two main blades 3 of the same group. side. Experiments have proved that the propeller blades can also use the mode of nine blades and three groups, one main blade and two auxiliary blades, and the effect is better if two auxiliary blades and one main blade cooperate to move.

[0075] It should be noted that all features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner except for mutually exclusive features and / or steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com