Organic and inorganic fertilizer same-machine different-position precision sowing machine for corn

A technology of inorganic fertilizer and precision seeder, applied in agricultural machinery and implements, planting methods, fertilization devices, etc., can solve the problems of simultaneous fertilization, inability to distinguish fertilizers, and many fertilization processes, so as to ensure the effect of vibration and pressure and reduce the possibility of , Enhance the effect of water absorption and breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

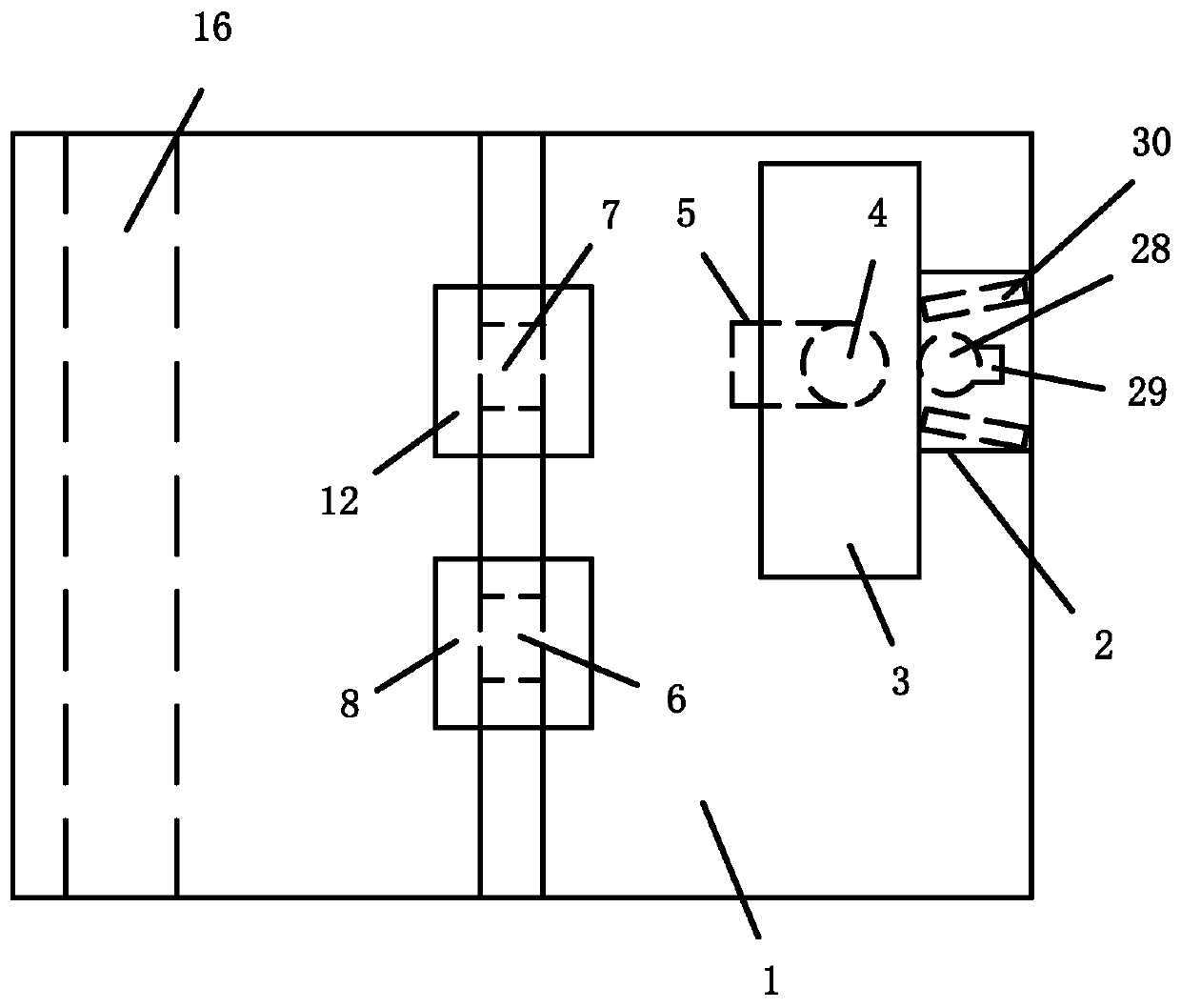

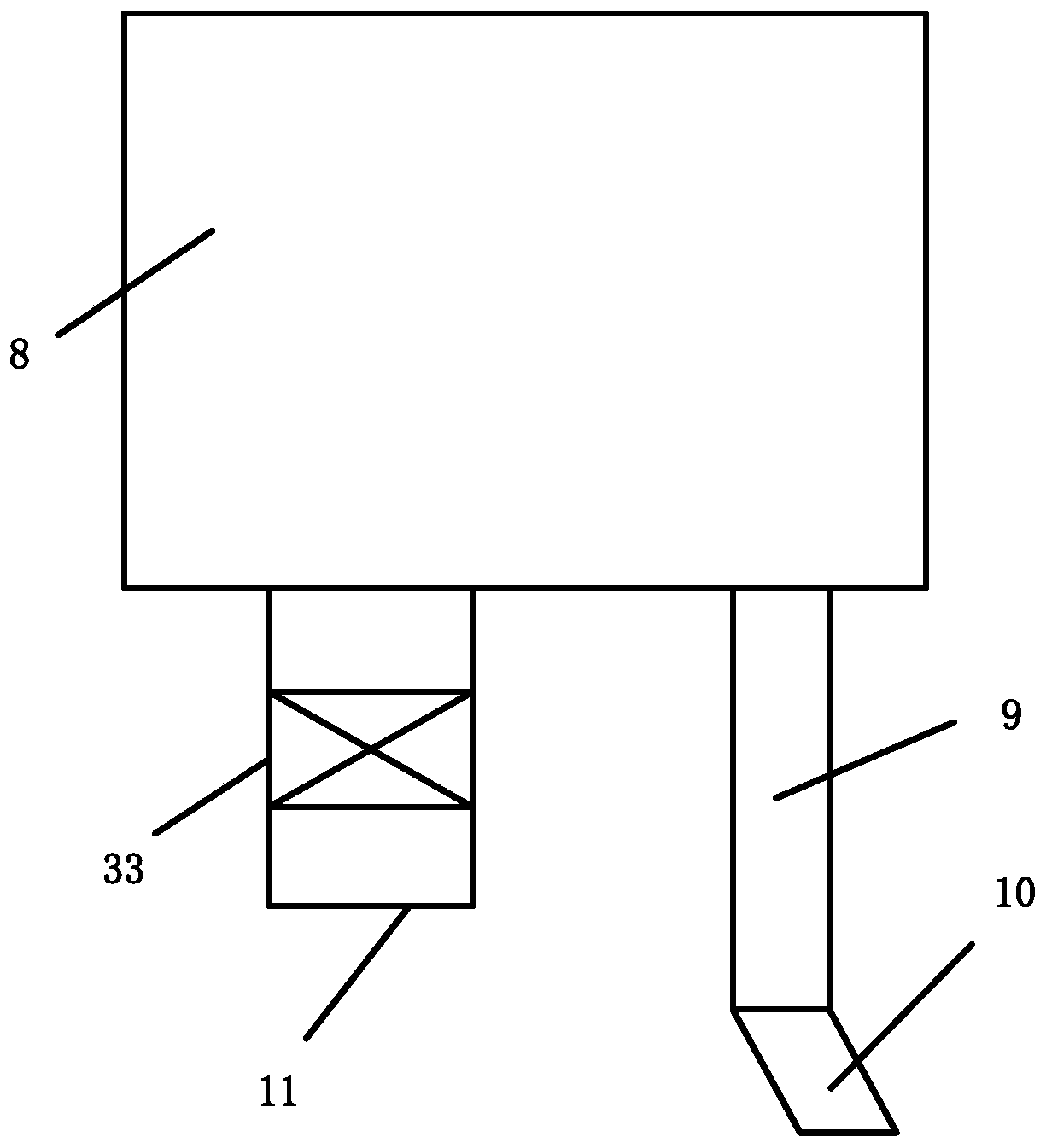

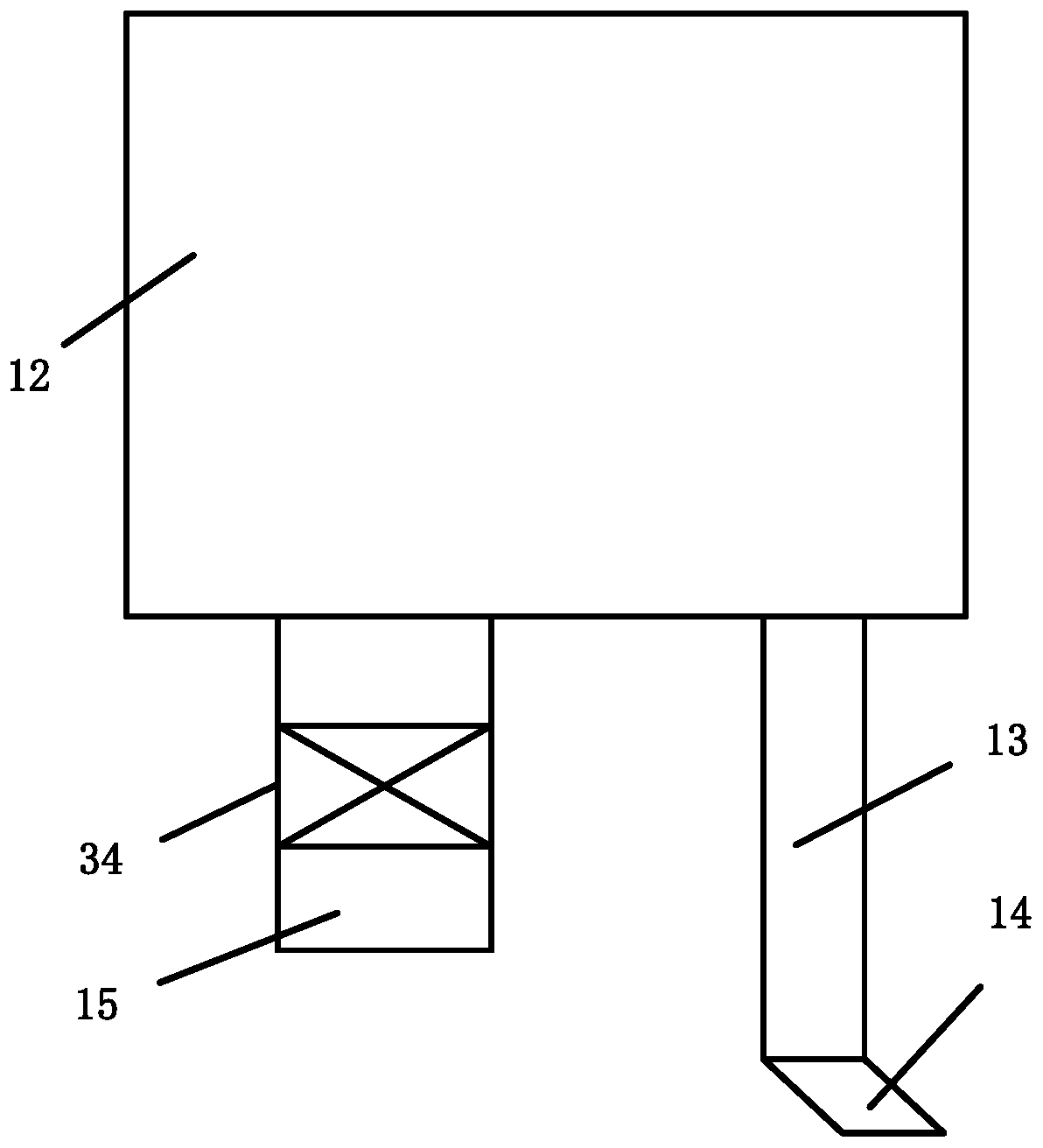

[0018] refer to Figure 1-6 , a specific embodiment of the present invention comprises frame 1, and frame 1 is provided with ditch opener 2, and the rear side of described ditch opener 2 is fixed with sowing box 3, and the bottom of sowing box 3 is connected with sowing tube 4, and sowing tube The end of 4 is provided with inclined pipe 5, and the distance between inclined pipe 5 and ditch opener 2 is 20~25cm; On frame 1, first slide block 6 and second slide block 7 are installed laterally, and first slide block 6 is fixed with an organic fertilizer box 8, the bottom of the organic fertilizer box 8 is connected to the first blade 10 through the first hydraulic cylinder 9, the angle between the first blade 10 and the horizontal plane is 65°, and the bottom of the organic fertilizer box 8 is connected with a first Feed pipe 11, the first regulating valve 33 is installed in the first feed pipe 11, the first feed pipe 11 is positioned at the rear side of the first spatula 10, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com