Shaftless type submersible axial flow electric pump

A technology of axial flow electric and submersible motors, applied in axial flow pumps, non-variable pumps, non-displacement pumps, etc., can solve the problems of reduced pump efficiency, impeller stuck, increased hydraulic loss, etc., to eliminate burning The effect of increasing the flow rate of the machine, increasing the water flow, and increasing the operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

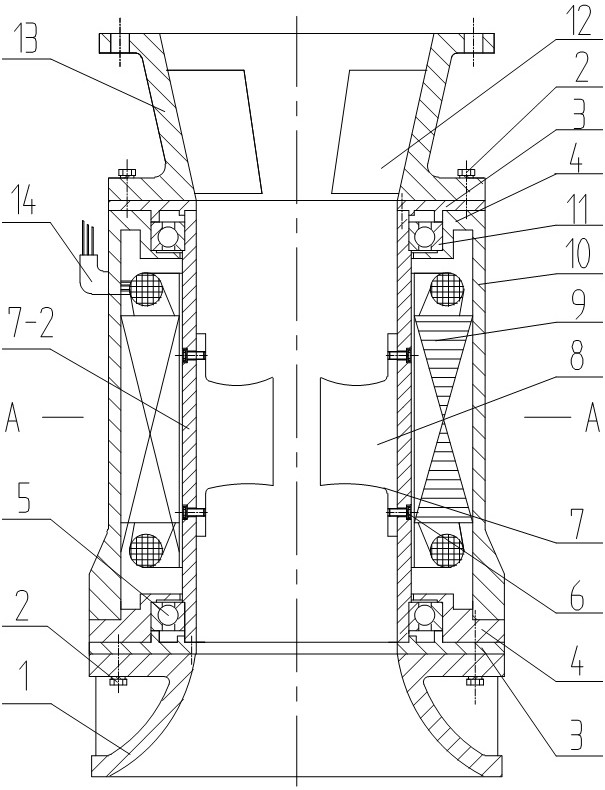

[0035] Example 1: figure 1 Shown is a diagram of a shaftless submersible axial flow pump.

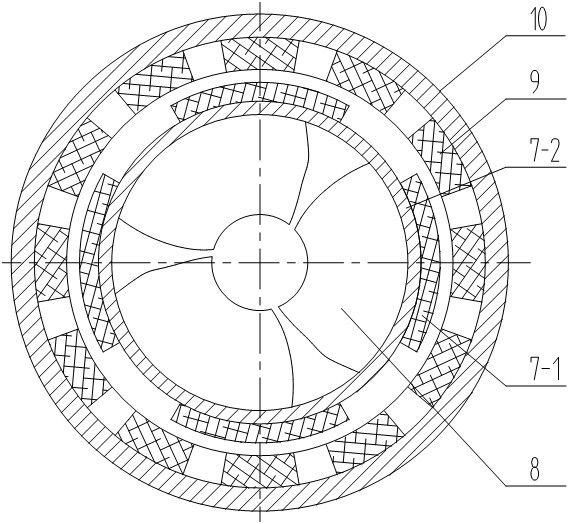

[0036] figure 2 Shown is a schematic diagram of the cross-sectional structure of the shaftless submersible axial flow pump A--A.

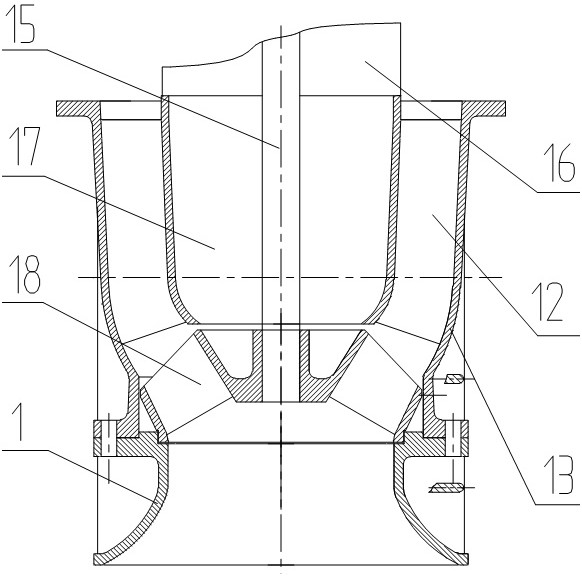

[0037] The water inlet section 1 is located at the bottom of the submersible electric pump and is designed in the shape of a bell mouth to guide the water flow into the inner cavity of the submersible electric pump. , the bearing support seat 4 and the machine casing 10 are closely connected together, and similarly, the guide body 13 is closely connected with the bearing sealing device 3, the bearing support seat 4 and the machine casing 10 through the fastening bolts 2 to form an integral Submersible electric pump;

[0038] The stator winding 9 of the submersible motor extends out of the submersible pump through the lead-out cable and the cable sealing device 14, the stator winding 9 of the submersible motor is tightly combined with the inner wall of t...

Embodiment 2

[0041] Embodiment 2: The bearing device described is a magnetic-fluid double-suspension support bearing; the rotor assembly 7 is supported on the magnetic-fluid double-suspension support bearing. The body is suspended in the space between the stator and the stator, and the suspended rotor assembly 7 is under the action of the high-speed rotating magnetic field of the stator winding 9, and the water pump blade 8 embedded in the inner cylinder rotates at a high speed together with the rotor bushing 7-2. High-speed rotation reduces the mechanical friction of the rotor and improves the efficiency of the pump.

[0042] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com