Hollow fibre membrane element

A fiber membrane and hollow technology, applied in the field of water treatment equipment, can solve the problem of difficult pollutants to be taken away, achieve smooth and continuous water intake, improve the effect of cleaning, and achieve the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

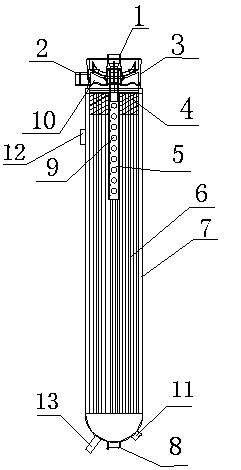

[0051] Such as figure 2 As shown, the hollow fiber membrane element of this embodiment is composed of a pressure-bearing housing 7 , a water distribution pipe 5 , a hollow fiber membrane 6 , and a head cover 3 .

[0052] Wherein, the pressure-bearing shell 7 is a cylindrical structure with one end closed of plastic material, and is made of a plastic pipe with an outer diameter of 225mm, an inner diameter of 215mm, and a length of 1.5m. The packaging cover 3 is hermetically arranged at the other end of the pressure-bearing housing 7 , and there is a cap cavity 10 in the middle of the package cover 3 , and the cap cavity 10 is provided with a cap liquid port 2 . The cover cavity 10 is isolated from the inside of the pressure-bearing type shell 7 . The water distribution pipe 5 is arranged inside the pressure-bearing housing 7 through the packaging cover 3; regularly distributed water distribution holes 9 are arranged on the water distribution pipe 5. The part of the water dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com